Potassium feldspar powder production and preparation method

A technology of potassium feldspar powder and potassium feldspar, which is applied in the field of production and preparation of potassium feldspar powder, can solve the problems of increasing the production cost of potassium feldspar powder, removing impurities and separating polluted ores, and high cost of wastewater treatment, achieving low production cost and no environmental pollution Harm, low recycling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

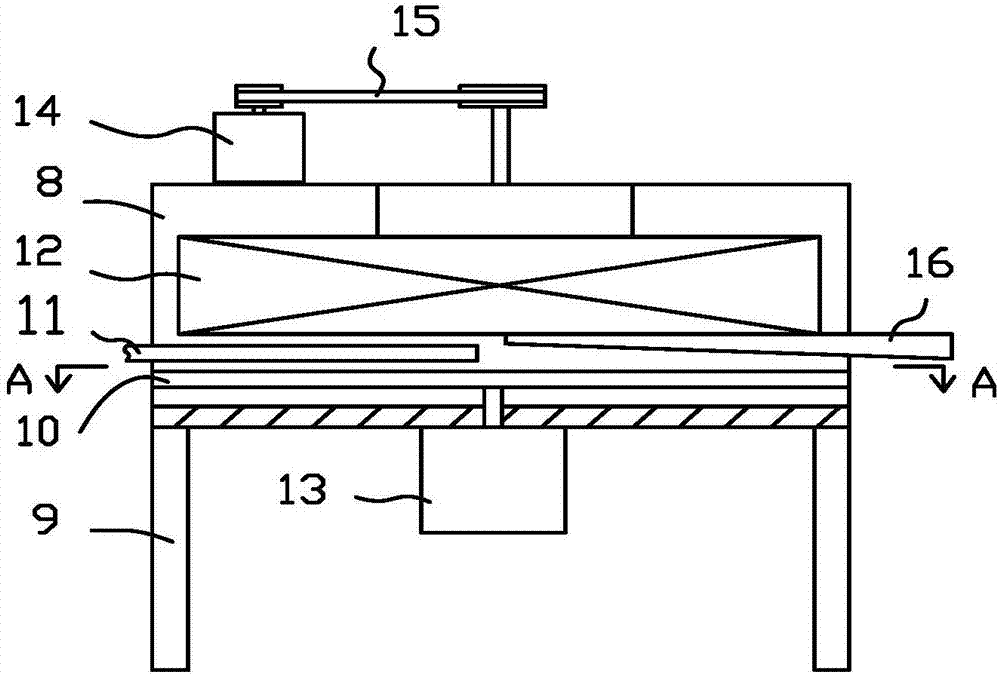

[0038] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

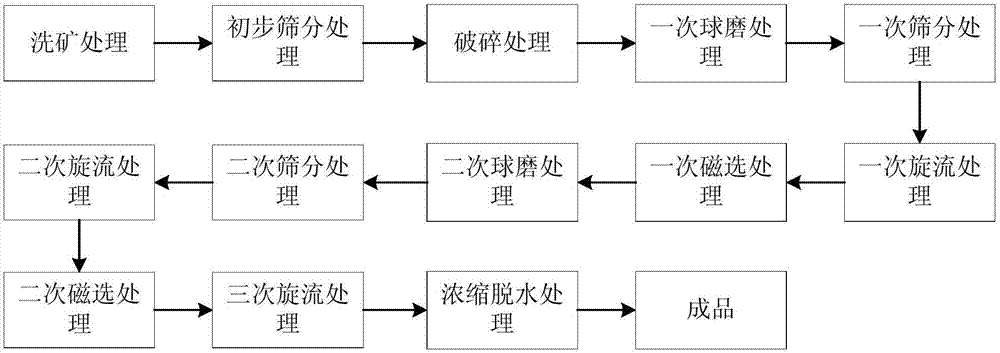

[0039] Such as figure 1 Shown, a kind of potassium feldspar powder production preparation method comprises the following processing steps:

[0040] 1. Ore washing treatment, after mining, the raw potassium feldspar ore is crushed and washed through a spiral chute to remove the sludge in the raw ore, and finally dehydrated for use.

[0041] 2. Preliminary screening treatment, the drained raw ore is sent to the ore color sorter, and the ore color sorter screens to obtain raw ore with a whiteness greater than 15%; specifically, the ore color sorter screens in the preliminary screening The raw ore with whiteness not less than 25% is obtained.

[0042] 3. Crushing treatment, the raw ore obtained by screening is crushed, and the ore crushed to a particle size of less than 1cm is obtained.

[0043] 4. A ball milling process, the ore is sent into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com