Fiberboard

A fiberboard and polyester fiberboard technology, applied in the field of fiberboard, can solve the problems of high cost, affecting the quality of the fiber itself, poor washing resistance of the auxiliary agent, etc., achieving good elasticity and tension, promoting healthy sleep, and avoiding the breeding effect of mites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

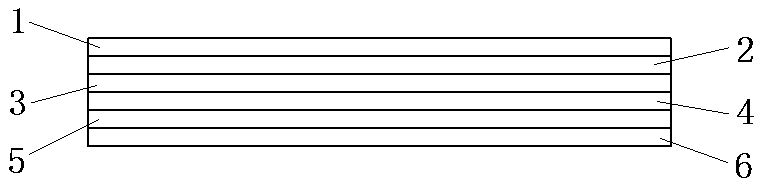

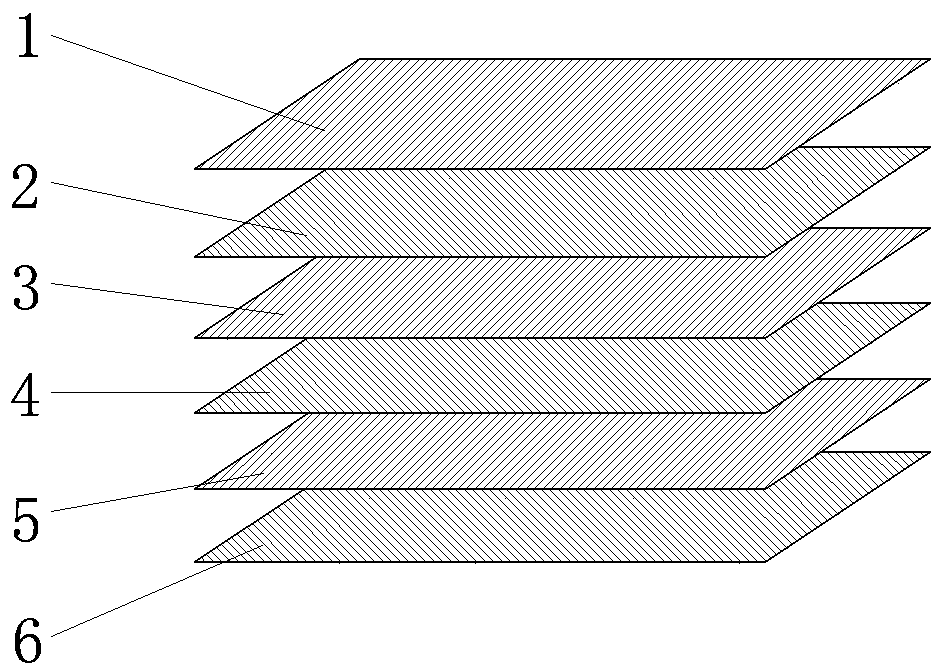

[0032](1) Take the low-melting point polyester fiber and the three-dimensional curly round hollow fiber with a mass ratio of 1:1, put them into a stirring grinder and pulverize them, and the particle size is 300 mesh; dry and mix evenly; pour into the reactive gel , fully mixed to obtain a mixture a; put the mixture a into a mold, and press the mixture under high pressure, with a temperature of 150° C. and a pressure of 2 MPa to obtain a fiberboard I layer 1;

[0033] (2) Take the low-melting point polyester fiber and the spiral renewable fiber with a mass ratio of 2:1, put them into a stirring grinder and pulverize them, and the particle size is 330 mesh; dry and mix evenly; pour in the reactive gel , fully mixed to obtain a mixture b; put the mixture b into a mold, and press the mixture under high pressure at a temperature of 155° C. and a pressure of 2.5 MPa to obtain the fiberboard II layer 2;

[0034] (3) Take the low-melting-point polyester fiber and hemp plant fiber wit...

Embodiment 2

[0040] (1) Take the low-melting polyester fiber and the three-dimensional curly round hollow fiber with a mass ratio of 1:5, put them into a stirring grinder and pulverize them, and the particle size is 400 mesh; dry and mix evenly; pour into the reactive gel , carry out thorough mixing to obtain the mixture a; put the mixture a into a mold, press the mixture under high pressure, the temperature is 155° C., and the pressure is 3 MPa to obtain the fiberboard I layer 1;

[0041] (2) Take the low-melting point polyester fiber and the spiral renewable fiber with a mass ratio of 6:1, put them into a stirring grinder and pulverize them, and the particle size is 490 mesh; dry and mix evenly; pour in the reactive gel , carry out thorough mixing to obtain mixture b; put the mixture b into a mold, press the mixture under high pressure, the temperature is 165° C., and the pressure is 3.5 MPa to obtain the fiberboard II layer 2;

[0042] (3) Take the low-melting-point polyester fiber and ...

Embodiment 3

[0048] (1) Take the low-melting point polyester fiber and the three-dimensional curly round hollow fiber with a mass ratio of 1:2, put them into a stirring grinder and pulverize them, and the particle size is 330 mesh; dry and mix evenly; pour into the reactive gel , carry out thorough mixing to obtain the mixture a; put the mixture a into a mold, press the mixture under high pressure, the temperature is 152° C., and the pressure is 2.5 MPa to obtain the fiberboard I layer 1;

[0049] (2) Take the low-melting polyester fiber and spiral renewable fiber with a mass ratio of 3.5:1, put them into a stirring grinder and pulverize them, and the particle size is 380 mesh; dry and mix evenly; pour into the reactive gel , fully mixed to obtain a mixture b; put the mixture b into a mold, and press the mixture under high pressure, with a temperature of 159° C. and a pressure of 2.8 MPa to obtain a fiberboard II layer 2;

[0050] (3) Take the low-melting point polyester fiber and hemp pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com