Method for high-efficiency preparation of high-purity sodium metavanadate

A technology of sodium metavanadate and sodium ammonium vanadate, applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., can solve the problem that the industrial powdery vanadium pentoxide is expensive and the powdery vanadium pentoxide has high quality requirements. , Incomplete removal of impurities by crystallization, etc., to achieve the effect of avoiding impurity wrapping, stable product quality, crystallization efficiency and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

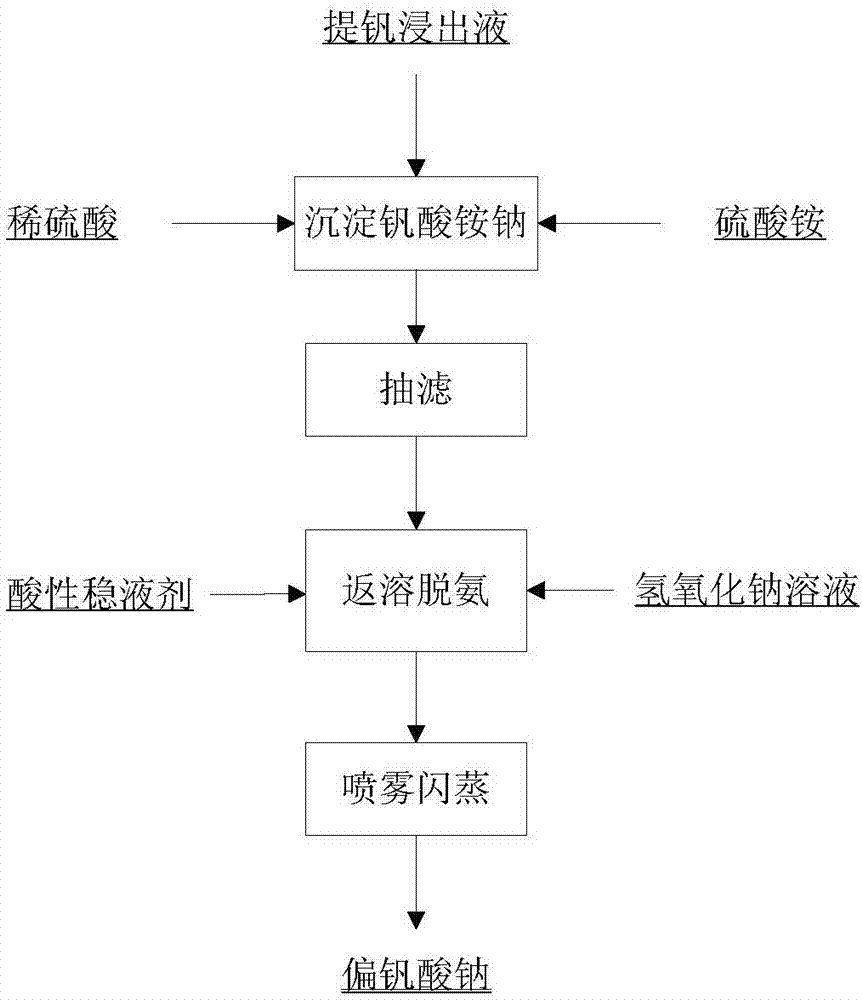

[0022] A preparation method of sodium metavanadate, the method may further comprise the steps:

[0023] A, add sulfuric acid and ammonium sulfate in vanadium extraction leaching solution;

[0024] b, adjust the pH of the solution to 4 to 6, and filter to obtain a solid sodium ammonium vanadate;

[0025] c. adding the sodium ammonium vanadate solid into the sodium hydroxide solution, deamination, and adjusting the pH value of the solution to 8-8.5 to obtain a sodium metavanadate solution;

[0026] d. Spray flash evaporation the sodium metavanadate solution to obtain sodium metavanadate solid.

[0027] The present invention adopts vanadium-extracting leaching liquid to be vanadium-titanium magnetite leaching vanadium solution, and its vanadium concentration is 20~50g / L, and silicon concentration is 1.0~6.0g / L, and chromium concentration is 2.0~8.0g / L; The clarity of sodium vanadate solution is not conducive to the dispersion of sodium metavanadate solution; hexavalent Cr is a ...

Embodiment 1

[0044] Take 3L of vanadium extraction solution, [V]35.2g / L, [Si]1.8g / L, [Cr]2.5g / L, add dilute sulfuric acid with a volume ratio of 1+4, adjust the pH value to 6.43, add 100g of ammonium sulfate, replenish Add 1+4 dilute sulfuric acid to pH 5.41, and filter to obtain orange ammonium ammonium vanadate sodium. Prepare 1L sodium hydroxide solution, the concentration of sodium hydroxide is 65g / L, add 250g sodium ammonium vanadate, heat to boiling, stir, degas, add acid stabilizer to adjust the pH value to 8.41, and obtain 1.1L sodium metavanadate solution. The solution was sprayed and flash evaporated using a NAI-GZJ small spray dryer, the drying temperature was 105°C, and the feed rate was 50mL / min to obtain 252.1g of light yellow sodium metavanadate powder with a purity greater than 99.6%, a yield of 99.4%, and a Cr content of 0.007 %, Si content 0.011%, Fe content 0.004%, As, P content < 0.001%; sodium metavanadate crystal particle size is uniform, particle size in -60 ~ +12...

Embodiment 2

[0046]Take 3L of vanadium extraction leaching solution, [V] 23.2g / L, [Si] 1.1g / L, [Cr] 2.1g / L, add dilute sulfuric acid with a volume ratio of 1+4, adjust the pH value to 6.73, add 100g of ammonium sulfate, replenish Add 1+4 dilute sulfuric acid to pH 5.01, filter to obtain orange ammonium ammonium vanadate sodium. Prepare 1L sodium hydroxide solution, the concentration of sodium hydroxide is 75g / L, add 250g sodium ammonium vanadate, heat to boiling, stir, degas, add acid stabilizer to adjust the pH value to 8.32, and obtain 1.2L sodium metavanadate solution. The solution was sprayed and flashed by NAI-GZJ small spray dryer, the drying temperature was 105°C, the feed rate was 50mL / min, and 165.8g of light yellow sodium metavanadate powder with a purity greater than 99.5% was obtained, the yield was 99.1%, and its Cr content was 0.006% , Si content 0.014%, Fe content 0.005%, As, P content <0.001%; sodium metavanadate crystal particle size is uniform, particle size in -60 ~ +...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com