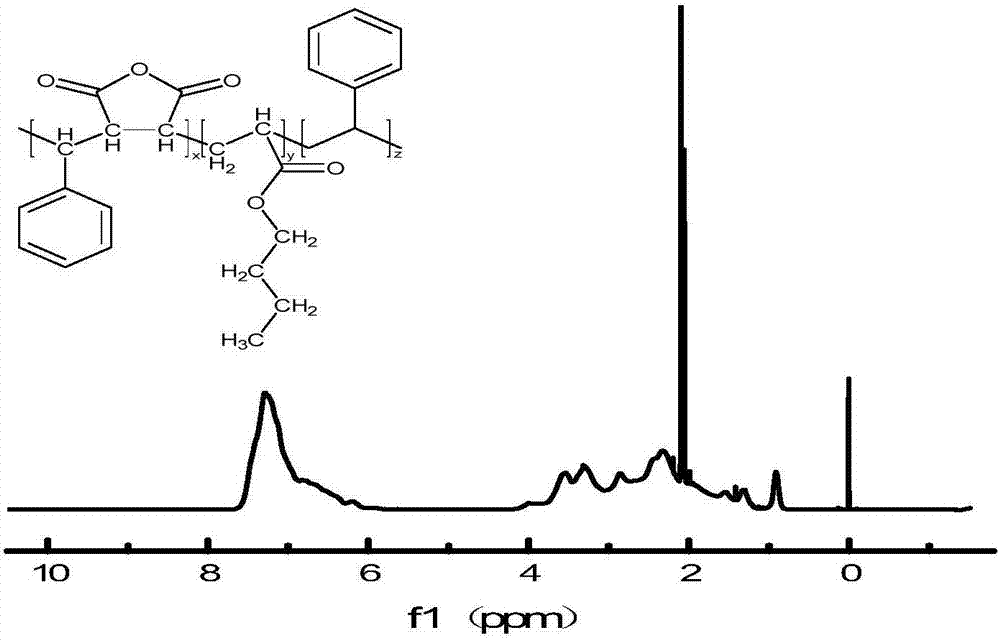

Multipolymer micro-nano particles and preparation method thereof

A technology of micro-nano particles and multi-copolymers, which is applied in the field of multi-copolymer micro-nano particles and their preparation, can solve problems such as poor water resistance, and achieve the effects of high preparation efficiency, improved water resistance, and easy recycling and reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

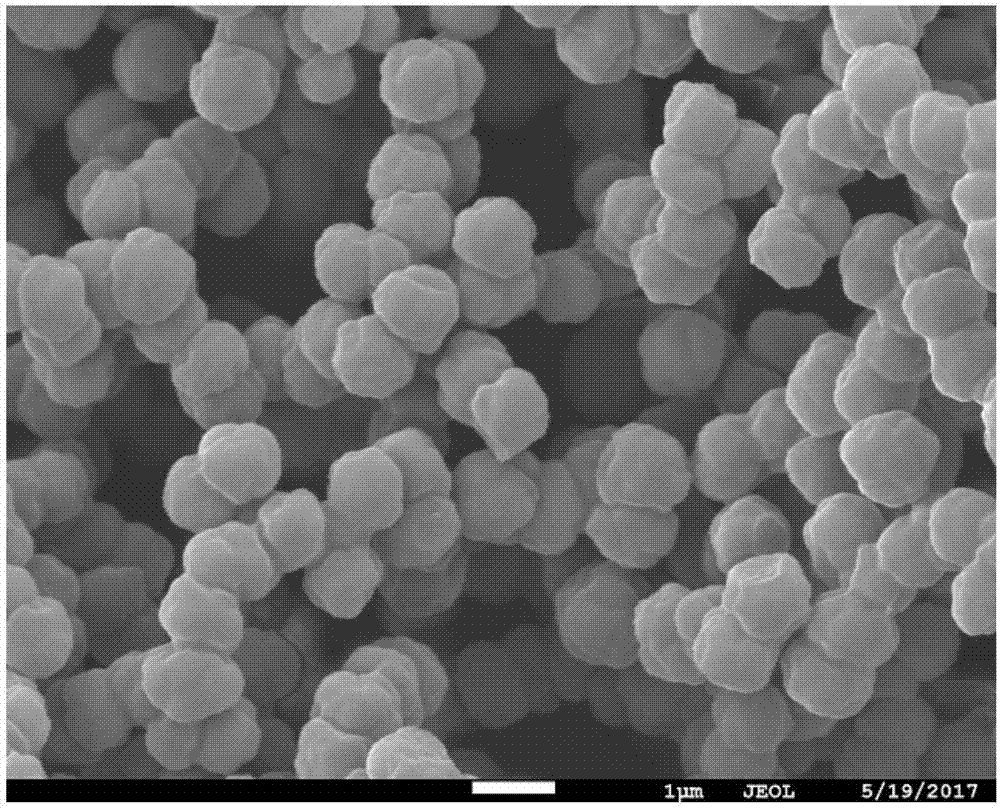

[0041] Embodiment 1: oil-soluble free radical initiator AIBN 0.025g is dissolved in 22.5g isoamyl acetate, adds St 1.25g, MAH 0.9423g, BA 0.2984g successively in the system (the mol ratio of St, MAH and BA is 5:4:1). After the monomers are dissolved and mixed evenly, the reaction system is ventilated with nitrogen for 30 minutes to remove oxygen; after that, the reaction system is placed in a constant temperature oil bath at 75°C, and the reaction time is set to 8 hours. After centrifugation for 10 min, the resulting copolymer microspheres were separated from the reaction system and dried. The yield of the polymer microspheres was 81%, and the particle diameter of the obtained terpolymer microspheres by scanning electron microscope was 423nm, and the particle size distribution was 1.02, the Tg of the terpolymer measured by DSC is 196°C, and the St:MAH:BA=0.4655:0.4456:0.0888 measured by elemental analysis.

Embodiment 2

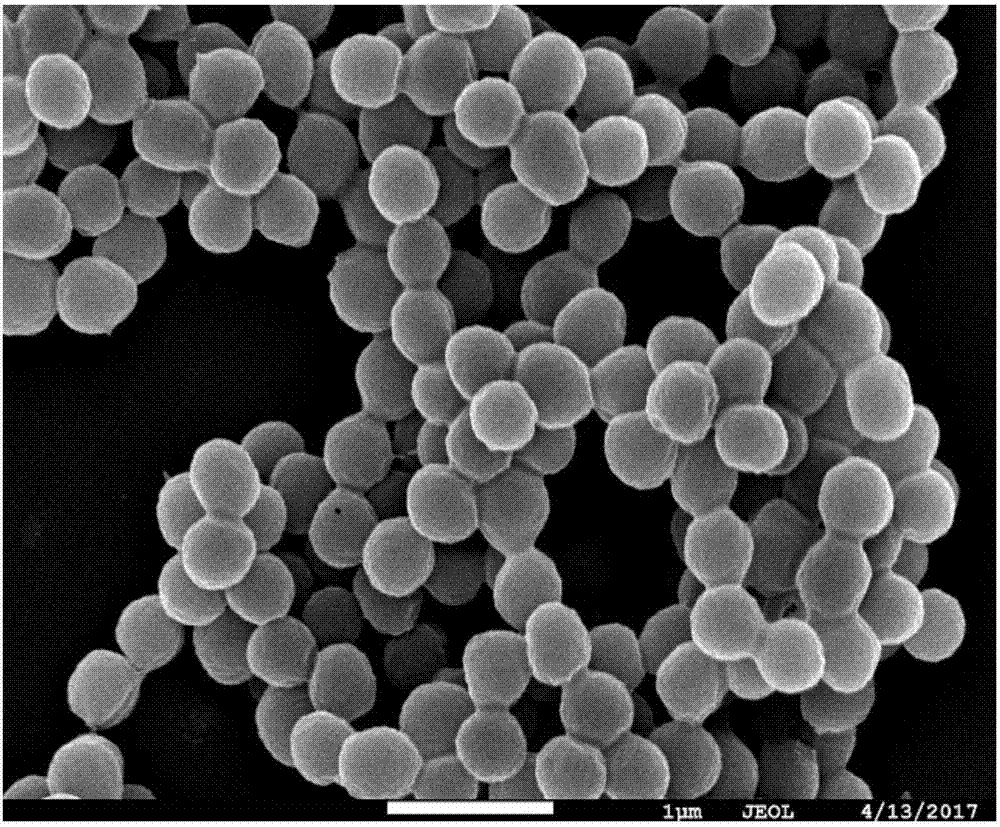

[0042] Embodiment 2: oil-soluble radical initiator AIBN 0.025g is dissolved in 22.5g isoamyl acetate, adds St 1.2149g, MAH 0.6869g, BA 0.5981g successively in the system (the mol ratio of St, MAH and BA is 5:3:2). After the monomers are dissolved and mixed evenly, the reaction system is ventilated with nitrogen for 30 minutes to remove oxygen; after that, the reaction system is placed in a constant temperature oil bath at 75°C, and the reaction time is set to 8 hours. After centrifugation for 10min, the copolymer microspheres obtained by the reaction were separated and dried from the reaction system, and the yield of the polymer microspheres was 60%. The particle diameter of the obtained terpolymer microspheres by scanning electron microscope was 389nm, and the particle size distribution was 1.03, the Tg of the terpolymer measured by DSC is 185° C., and the St:MAH:BA=0.4685:0.4208:0.1106 measured by elemental analysis.

Embodiment 3

[0043] Embodiment 3: oil-soluble free radical initiator AIBN 0.025g is dissolved in the mixed solvent of 18.75g isoamyl acetate and 3.75g n-heptane (the mass ratio of isoamyl acetate and n-heptane is 5:1), Add St1.2149g, MAH0.6869g, BA0.5981g to the system in turn (the molar ratio of St, MAH and BA is 5:3:2). After the monomers are dissolved and mixed evenly, the reaction system is ventilated with nitrogen for 30 minutes to remove oxygen; after that, the reaction system is placed in a constant temperature oil bath at 75°C, and the reaction time is set to 8 hours. After centrifugation for 10min, the copolymer microspheres obtained by the reaction were separated and dried from the reaction system, and the polymer microsphere yield was 78%, and the particle diameter of the terpolymer microspheres obtained by the scanning electron microscope was 288nm, and the particle size distribution was 1.01, the Tg of the terpolymer measured by DSC is 178° C., and the St:MAH:BA=0.4545:0.4212:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com