Gas chromatography detection method and preparation method of iodometyl pivalate

A technology of iodomethyl pivalate and a detection method, applied in the gas chromatography detection method of iodomethyl pivalate and the field of preparation thereof, can solve the problems of complicated operation, difficult application, high cost and the like, and achieve high product yield , good purity, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

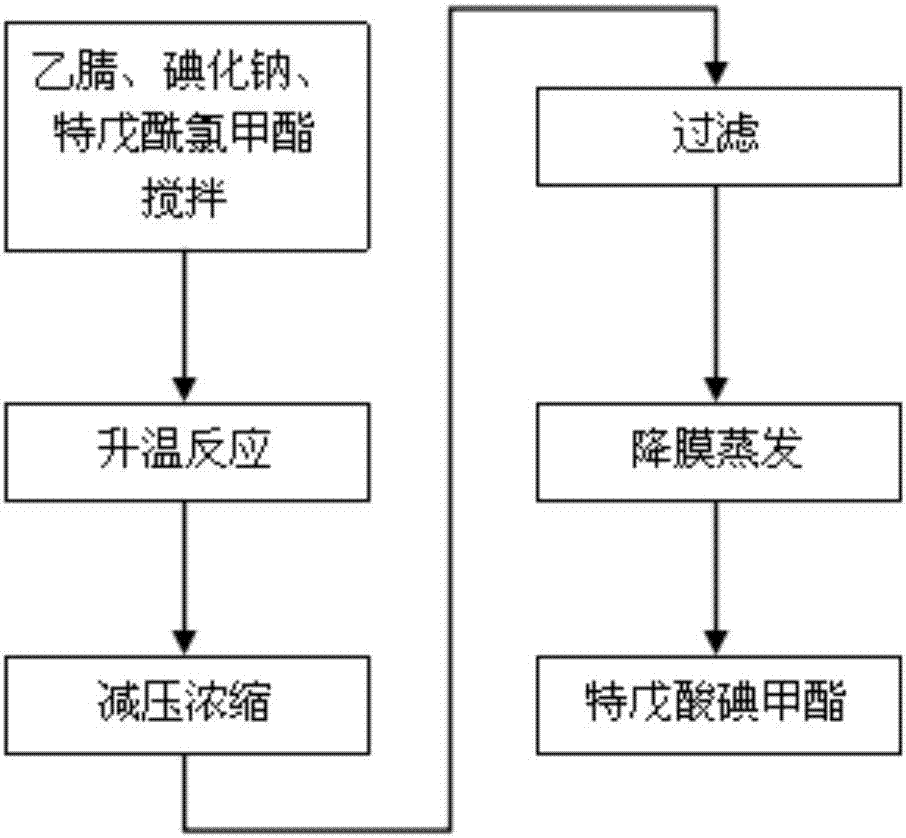

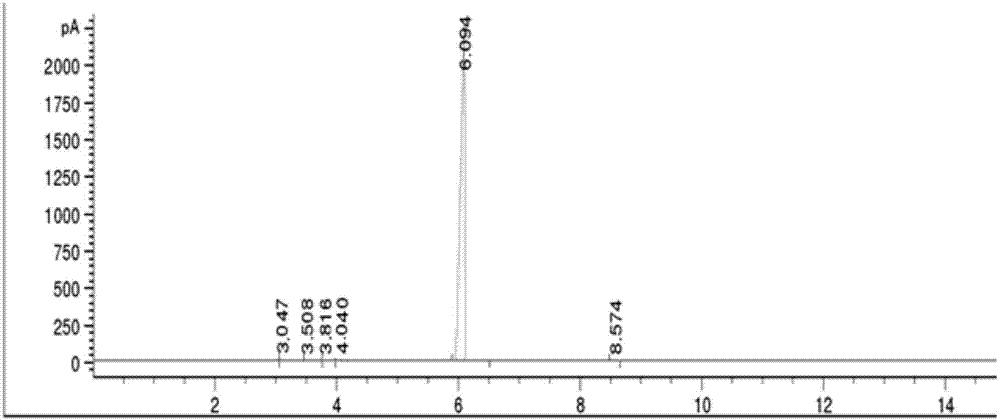

preparation Embodiment 1

[0109] Add 50ml of acetonitrile and 13.2g of sodium iodide to a 250ml single-necked bottle, stir and raise the temperature to 50°C, add 12g of pivaloyl chloride methyl ester, and react for 1h. The liquid was concentrated under reduced pressure at 20°C until a large amount of solids were precipitated, and 90 ml of dichloromethane was added for filtration. The filtrate was passed through a 30° C. falling film evaporator at 2 ml / min to obtain 18.5 g of iodomethyl pivalate with a yield of 95.9% and a product purity of 99.8%.

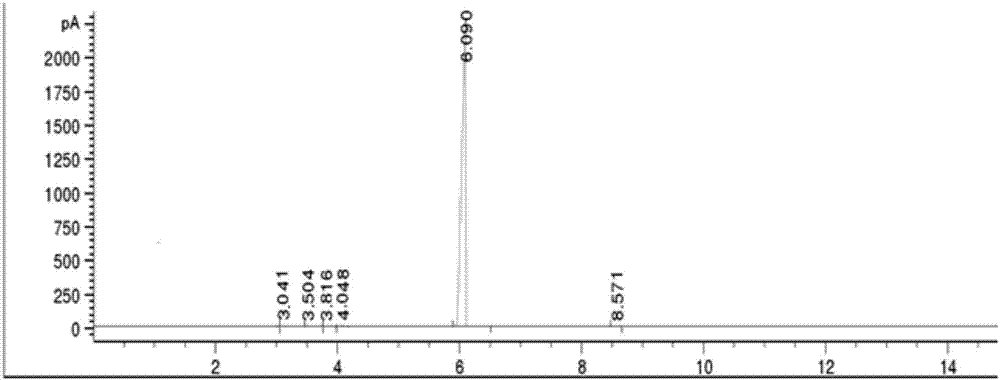

preparation Embodiment 2

[0111] Add 36ml of ethyl acetate and 15.0g of sodium iodide to a 250ml single-necked bottle, stir and raise the temperature to 40°C, add 12g of pivaloyl chloride methyl ester, and react for 3h. The liquid was concentrated under reduced pressure at 25°C until a large amount of solids were precipitated, and 72ml of dichloromethane was added for filtration. The filtrate was passed through a 40°C falling film evaporator at 2.5ml / min to obtain 18.2g of iodomethyl pivalate with a yield of 94.4% and a product purity of 99.8%.

preparation Embodiment 3

[0113] Add 72ml of acetone and 16.8g of sodium iodide to a 250ml single-necked bottle, stir and raise the temperature to 30°C, add 12g of pivaloyl chloride methyl ester, and react for 2h. Concentrate the liquid under reduced pressure at 30°C until a large amount of solid precipitates, add 100ml of dichloromethane and filter. The filtrate was passed through a 50° C. falling film evaporator at 3 ml / min to obtain 18.0 g of iodomethyl pivalate with a yield of 93.4% and a product purity of 99.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com