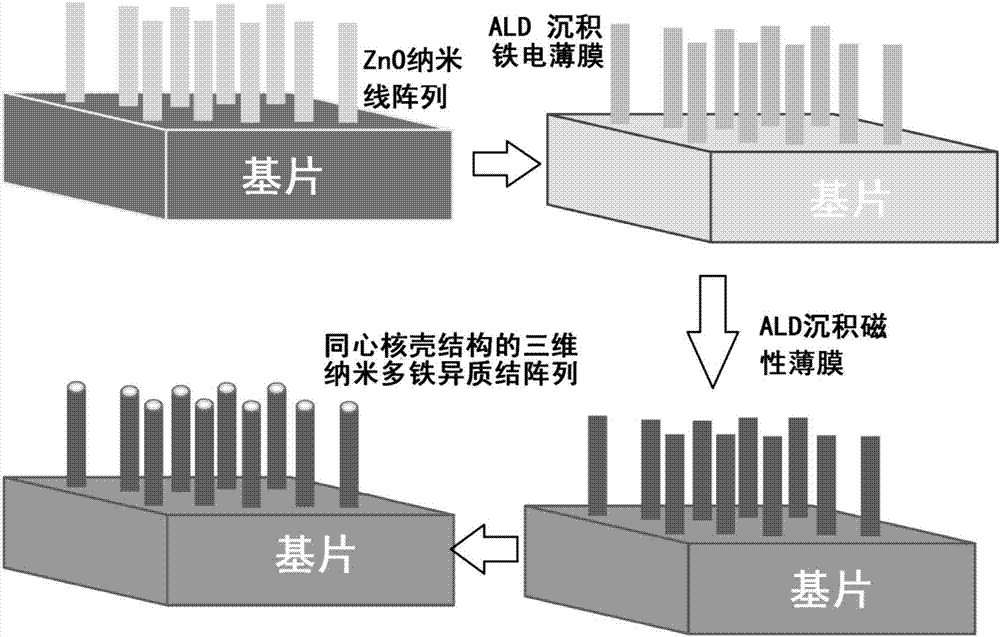

Method for constructing concentric nuclear-shell three-dimensional nano multi-ferroic heterojunction array by ALD

A multiferroic heterojunction, three-dimensional nanotechnology, applied in the fields of nanotechnology for information processing, nanotechnology for materials and surface science, nanotechnology, etc. Staying in the plane structure and other problems, to achieve the effect of simple and easy preparation process, simple operation, and improved integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Include the following steps:

[0033] 1) The ZnO single crystal nanowire array grown on the FTO or ITO conductive glass by the hydrothermal method, and the surface is cleaned by dry nitrogen blowing for later use;

[0034] 2) The ZnO nanowire array grown on the conductive glass in step 1) is sent to the atomic layer deposition system through the vacuum loading robot arm of the atomic layer deposition system, and the ZnO nanowire array substrate is heated to 200°C-300°C for Prepare for deposition of ferroelectric thin film materials;

[0035] 3) On the basis of step 2), cyclopentadiene grade Ba[(cp-Ba)-type] and deionized water (H 2 O) was used as Ba and O precursor sources respectively, and uniform conformal BaTiO was deposited on the surface of ZnO nanowires by ALD technique. 3 Thin film formed BaTiO 3 / ZnO core-shell structure; or using bis(2,2,6,6,-tetramethyl-3,5-heptanedionate) lead [P b (DPM 2 )], titanium tetraisopropoxide [Ti(Oi–Pr) 4 ], tetrakis (ethylmet...

Embodiment 2

[0041] Include the following steps:

[0042] 1) The surface of the ZnO single crystal nanowire array grown on FTO or ITO conductive glass by hydrothermal method is purged and cleaned with dry nitrogen for further use.

[0043] 2) The ZnO nanowire array grown on the conductive glass in step 1 is sent to the atomic layer deposition system through the vacuum loading robot arm of the atomic layer deposition system, and the ZnO nanowire array substrate is heated to 200°C-300°C Prepare for deposition of ferroelectric thin film materials.

[0044] 3) On the basis of step 2), cyclopentadiene grade Ba[(cp-Ba)-type] and deionized water (H 2 O) was used as Ba and O precursor sources respectively, and uniform conformal BaTiO was deposited on the surface of ZnO nanowires by ALD technique. 3 Thin film formed BaTiO 3 / ZnO core-shell structure; or using bis(2,2,6,6,-tetramethyl-3,5-heptanedionate) lead [P b (DPM 2 )], titanium tetraisopropoxide [Ti(Oi–Pr) 4 ], tetrakis (ethylmethylamino...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com