Heat medium liquid

A heat medium and antifreeze technology, applied in heat exchange materials, additives, petroleum industry, etc., can solve the problems of increased foaming of heat medium liquid, inability to circulate heat medium liquid, and increasing the volume of heat release bodies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

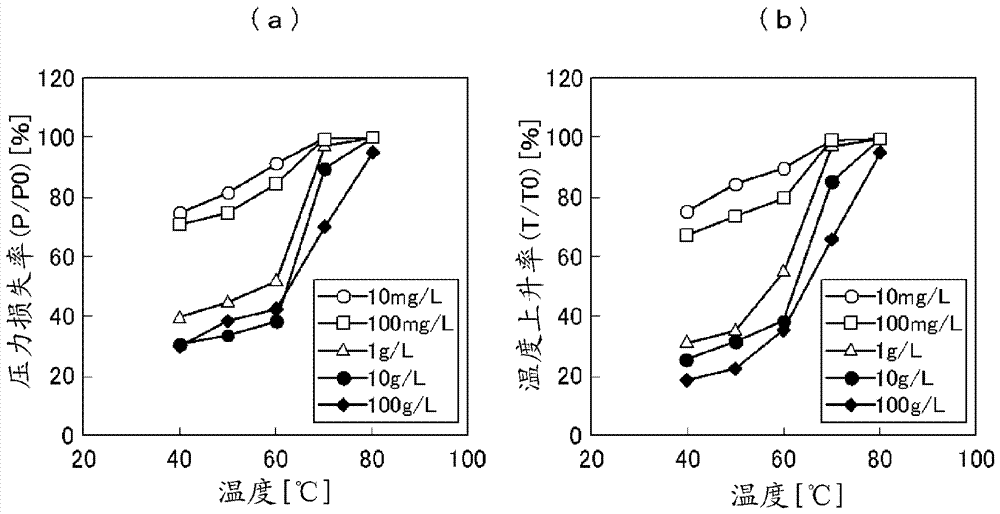

[0079] A heat medium solution for a test was prepared by adding xanthan gum (manufactured by Sanjing Co., Ltd., a type of water-soluble polymer compound) to the reference heat medium so as to have a test concentration. With regard to this test heat medium liquid, the pressure loss P and the temperature increase T were measured in the same procedure as the above reference heat medium. The test concentrations were 10mg / L, 100mg / L, 1g / L, 10g / L, and 100g / L. express the result in figure 1 middle. exist figure 1 , under the downstream side pressure P and downstream side temperature T of each straight pipe section, the ratio (=P / P0, T / T0) of the downstream side pressure P0 and the downstream side temperature T0 of the reference heat medium is obtained as the pressure loss rate , Temperature rise rate, expressed in percentage.

Embodiment 2)

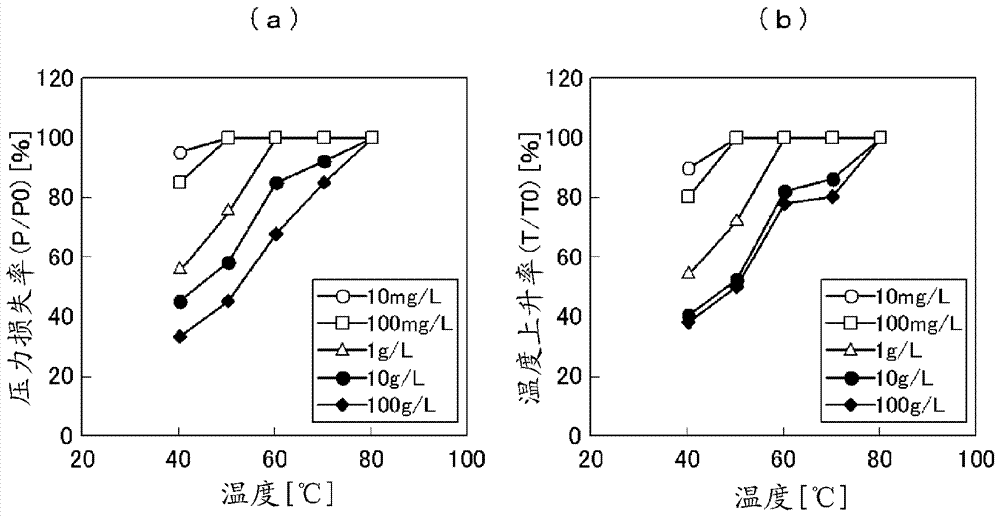

[0081] A heat medium solution for a test was prepared by adding poly(ethylene glycol)(propylene glycol) copolymer stearate (manufactured by Nikko Chemical Karls Co., Ltd.) to the reference heat medium so as to have a test concentration. With regard to this test heat medium liquid, the pressure loss P and the temperature increase T were measured in the same procedure as the above reference heat medium. express the result in figure 2 middle.

Embodiment 3)

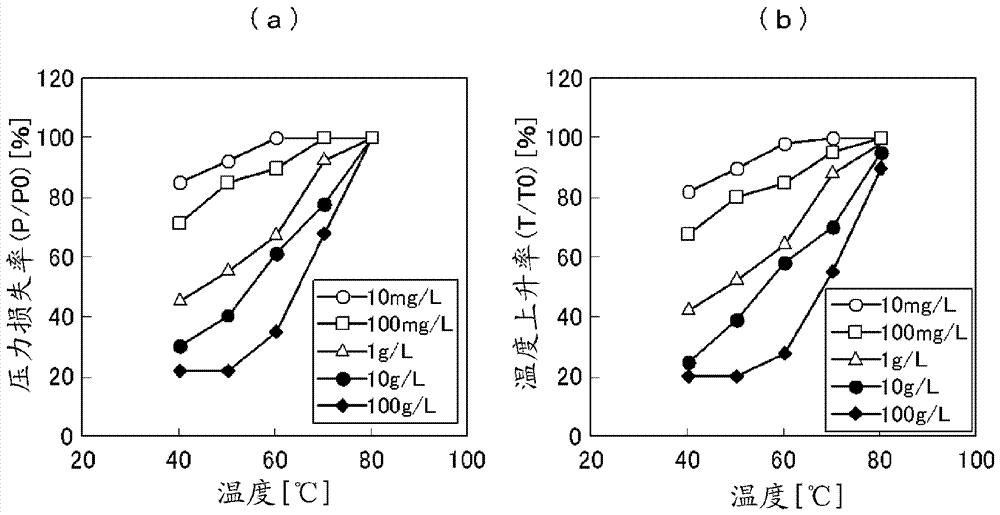

[0083]A heat medium liquid for testing was prepared by adding a sulfonated tetrafluoroethylene polymer (Wako Pure Chemical Industries, Ltd., product name: Nafion 20) to the reference heat medium to obtain a test concentration. With regard to this test heat medium liquid, the pressure loss P and the temperature increase T were measured in the same procedure as the above reference heat medium. express the result in image 3 middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com