Vegetable cold storage method

A vegetable and refrigeration device technology, which is applied in the fields of fruit and vegetable preservation, food freezing, and preservation of fruits/vegetables through freezing/refrigeration, etc. It can solve the problems of bad smell, low moisture content, and peculiar smell of refrigeration devices, so as to improve the shelf life and production cost. Low, extended shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

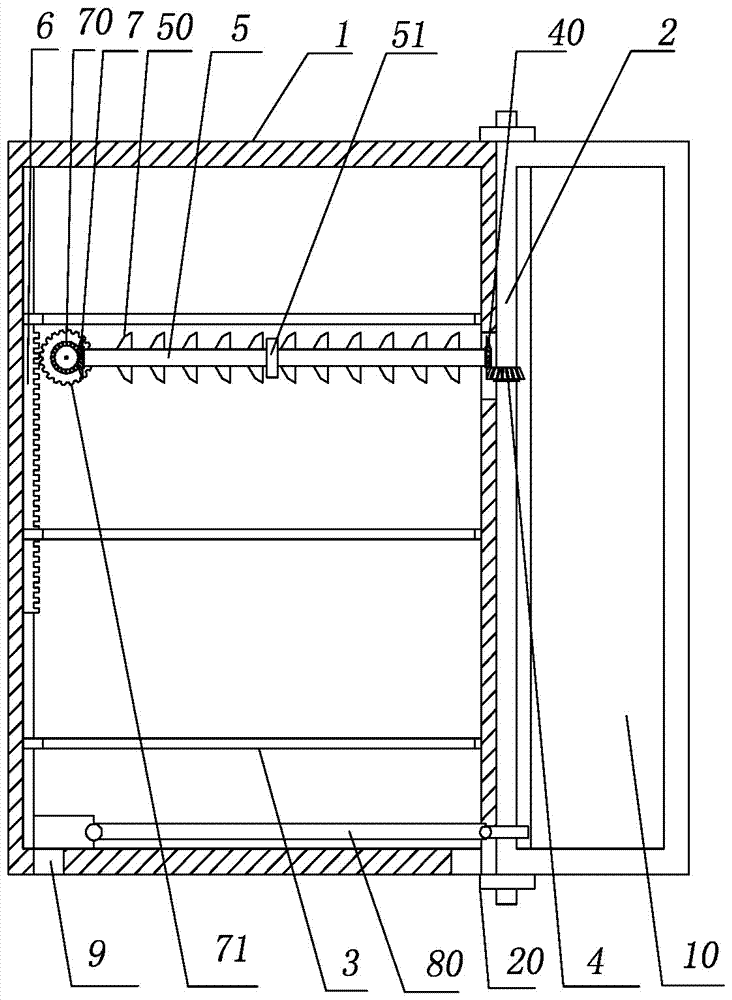

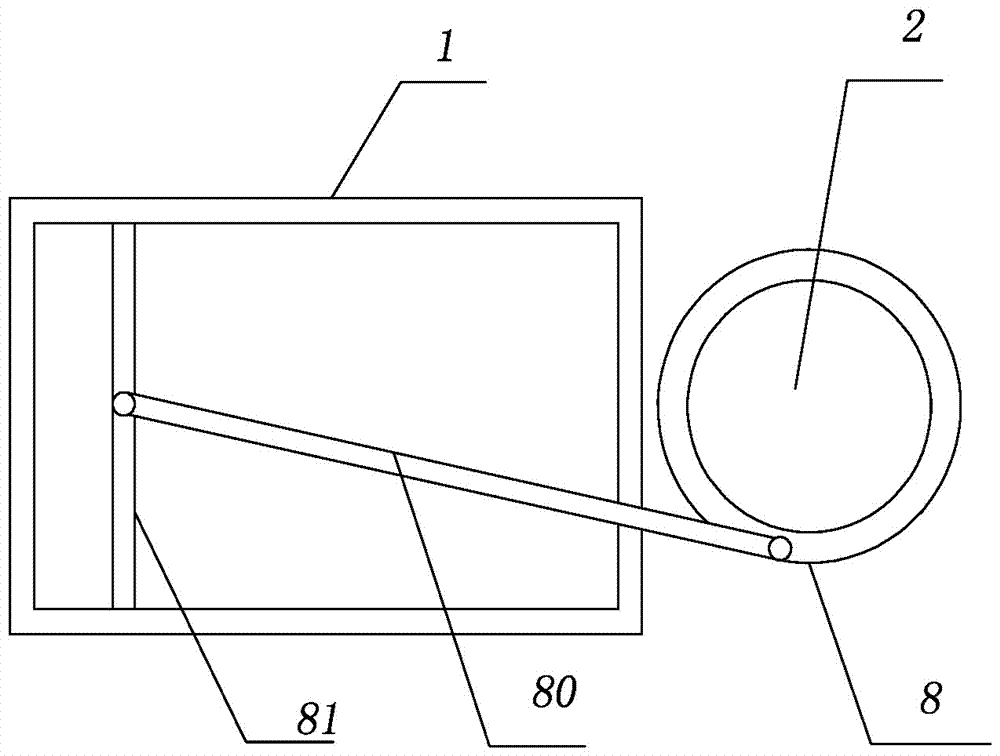

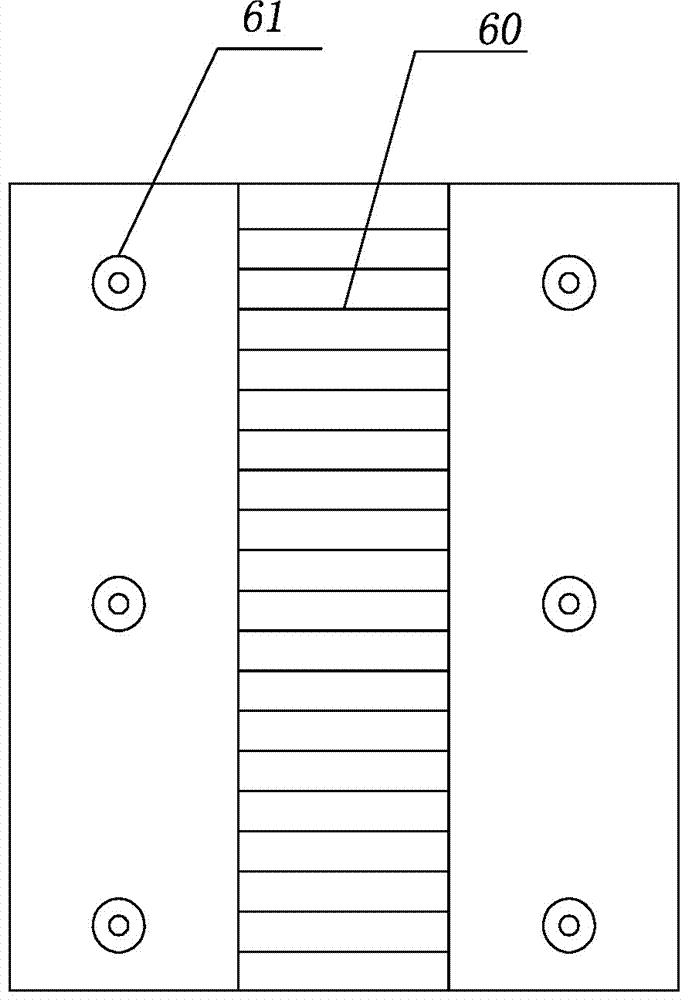

[0032] as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 Shown: the method for refrigerating vegetables, using a vegetable refrigerating device for refrigerating; the vegetable refrigerating device includes a refrigerating body 1 and a case cover 10 for covering the refrigerating body 1 , and a rotating shaft 2 is connected between the refrigerating body 1 and the case cover 10 , and the rotating shaft 2 Respectively be provided with a fixed ring 20 at the upper and lower ends of the upper and lower ends, be used for fixing rotating shaft 2, simultaneously rotating shaft 2 and case cover 10 are integrally connected, when rotating case cover 10 like this, rotating shaft 2 also can rotate together thereupon. The refrigerator body 1 is provided with several layers of placement trays 3, a drainage mechanism, a spray structure, a sweeping structure, an active mechanism and a passive mechanism.

[0033] Such as Figure 4 As shown, the placement...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is: in step B, the temperature inside the refrigerator body 1 is 6°C, in step C, the nozzle 61 is activated twice a day, and in step D, the frequency of opening the lid 10 is once a day.

Embodiment 3

[0048] The difference between this embodiment and Embodiment 1 is: in step B, the temperature inside the refrigerator body 1 is 8°C, in step C, the nozzle 61 is started 3 times a day, and in step D, the frequency of opening the box cover 10 is 2 times a day.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com