Carbon nanotube (CNT) reinforced injectable antibacterial conductive nano composite haemostatic cryogel dressing as well as preparation method and application thereof

A carbon nanotube and conductive nanotechnology, applied in the field of injectable antibacterial conductive nanocomposite hemostatic crystal glue dressing and its preparation, can solve problems such as loss of effect, and achieve the effects of promoting healing and promoting the formation of vascularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the present invention comprises the following steps:

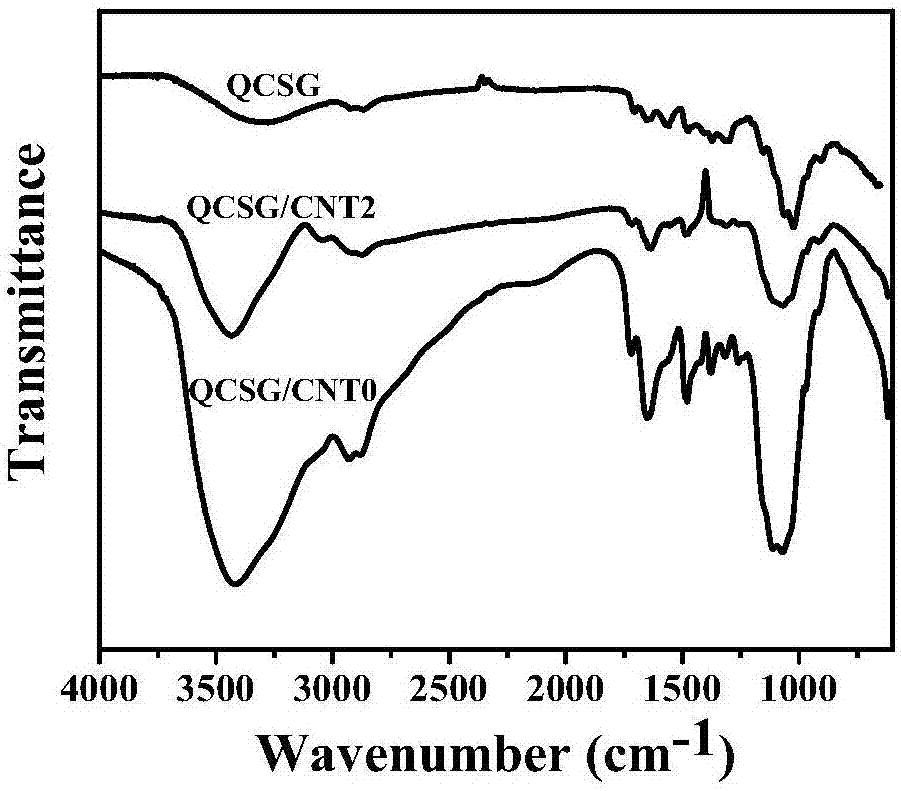

[0047] 1) Preparation of QCSG (glycidyl methacrylate functionalized quaternized chitosan, glycidyl methacrylate functionalized quaternized chitosan) polymer: 0.8-1.2 g of chitosan was resuspended in 36 mL of deionized water, and then 180 μL of Glacial acetic acid was added dropwise while stirring, and then heated at 50-60°C and stirred for 30-60 minutes. Subsequently, 773 μL˜2319 μL of GTMAC (glycidyltrimethylammonium chloride, glycidyltrimethylammonium chloride) was added dropwise to the chitosan solution. Then keep stirring at 50-60°C and react for 15-18 hours. After the reaction, 382.16-764.32 μL of GMA (glycidyl methacrylate, glycidyl methacrylate) was added to the above reaction solution respectively, and then the reaction was continued at 50-60° C. in the dark for 15-18 hours. A preferred reaction is to use 1.0 g of chitosan, heat the reaction at 55°C, 2319 μL of GTMAC, and 382.16 μ...

Embodiment 1

[0054] 1) One-pot preparation of QCSG polymer: 1 g of chitosan was resuspended in 36 mL of deionized water, then 180 μL of glacial acetic acid was added dropwise with stirring, and then heated at 55°C and stirred for 30 min. Then 2319 μL of GTMAC was added dropwise to the chitosan solution. Subsequently, stirring was continued at 55° C. for 15 h. After the reaction was completed, 382.16 μL of GMA was added dropwise to the reaction solution, and then the reaction was continued for 15 h at 55° C. in the dark. After the reaction, the reaction solution was centrifuged at 7000 rpm for 20 min, and then the supernatant was precipitated in pre-cooled acetone to obtain a crude product of QCSG. The crude QCSG product was subsequently dissolved in deionized water and dialyzed for three days using a dialysis bag with a molecular cutoff of 3500 DA. After dialysis, the purified QCSG product was obtained by lyophilization.

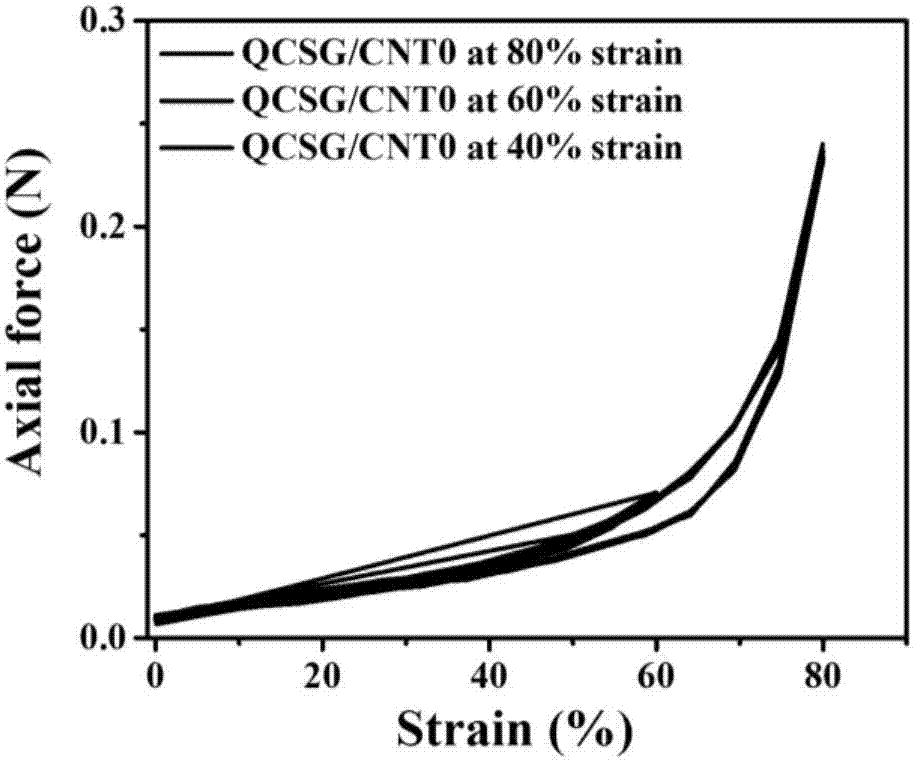

[0055] 2) Preparation of QCSG / CNT0 gel: the QCSG polymer was pre...

Embodiment 2

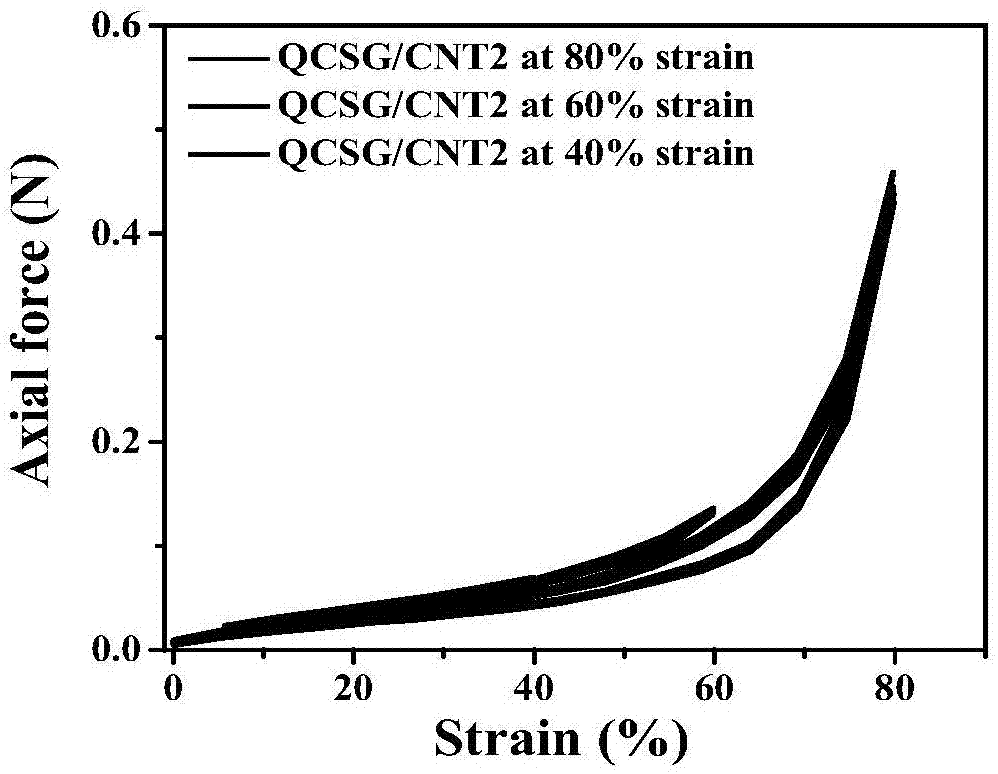

[0057] 1) One-pot preparation of QCSG polymer: 1 g of chitosan was resuspended in 36 mL of deionized water, then 180 μL of glacial acetic acid was added dropwise with stirring, and then heated at 55°C and stirred for 30 min. Then 2319 μL of GTMAC was added dropwise to the chitosan solution. Subsequently, stirring was continued at 55° C. for 15 h. After the reaction was completed, 382.16 μL of GMA was added dropwise to the reaction solution, and then the reaction was continued for 15 h at 55° C. in the dark. After the reaction, the reaction solution was centrifuged at 7000 rpm for 20 min, and then the supernatant was precipitated in pre-cooled acetone to obtain a crude product of QCSG. The crude QCSG product was subsequently dissolved in deionized water and dialyzed for three days using a dialysis bag with a molecular cutoff of 3500 DA. After dialysis, the purified QCSG product was obtained by lyophilization.

[0058] 2) Preparation of PF127-DA polymer: Dissolve 2.54g of PF1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com