Composite rockwool panel with flexible surface layers and preparation method of composite rockwool panel

A flexible surface, rock wool board technology, applied in the field of building thermal insulation materials, can solve the problems of low water absorption and thermal conductivity, high price, unacceptable, etc., achieve superior tensile and crack resistance, improve crack resistance, and improve adhesion The effect of connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

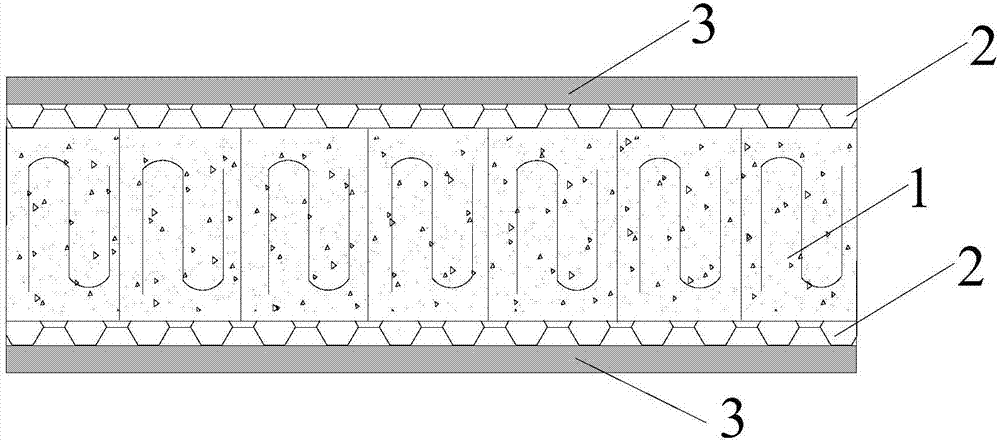

[0023] The flexible surface layer composite rock wool board provided by the present invention has a layered structure, which are respectively from bottom to top: flexible surface layer 3, adhesive layer 2, middle insulation layer 1, adhesive layer 2 and flexible surface layer 3, The middle insulation layer 1 and the flexible surface layer 3 are bonded by an adhesive layer 2, the middle insulation layer 1 is rock wool, the adhesive layer 2 is foamed polyurethane, and the flexible surface layer 3 Coated fiberglass mat for cement.

[0024] A method for preparing a flexible surface layer composite rock wool board, the steps are as follows: 1) Prepare two layers of cement-coated fiberglass mats, lay one layer of cement-coated fiberglass mats on the production line, Spray 2mm foam polyurethane on the upper surface;

[0025] 2) Laying rock wool on cement-coated fiberglass felt sprayed with polyurethane foam;

[0026] 3) Spray 2 mm of foamed polyurethane on the upper surface of the ...

Embodiment 2

[0030] The flexible surface layer composite rock wool board provided by the present invention has a layered structure, which are respectively from bottom to top: flexible surface layer 3, adhesive layer 2, middle insulation layer 1, adhesive layer 2 and flexible surface layer 3, The middle insulation layer 1 and the flexible surface layer 3 are bonded by an adhesive layer 2, the middle insulation layer 1 is rock wool, the adhesive layer 2 is foamed polyurethane, and the flexible surface layer 3 For cement coated cloth.

[0031] A preparation method for a flexible surface layer composite rock wool board, the steps are as follows: 1) prepare two layers of cement-coated cloth, lay one layer of cement-coated cloth on the production line, and spray 3mm hair on the upper surface of the cement-coated cloth. Polyurethane foam;

[0032] 2) Lay the rock wool on the cement-coated cloth sprayed with foamed polyurethane;

[0033] 3) Spray 3mm polyurethane foam on the upper surface of the...

Embodiment 3

[0037] A flexible surface layer composite rock wool board provided by the present invention has a layered structure, and the flexible surface layer composite rock wool board has a layered structure, which are respectively: flexible surface layer 3, adhesive layer 2, middle Insulation layer 1, adhesive layer 2 and flexible surface layer 3, the middle insulation layer 1 and the flexible surface layer 3 are bonded by adhesive layer 2, the middle insulation layer 1 is rock wool, and the adhesive The knot layer 2 is foamed polyurethane, and the flexible surface layer 3 is cement coated cloth.

[0038] A preparation method of a flexible surface layer composite rock wool board, the steps are as follows: 1) prepare two layers of cement-coated cloth, lay one layer of cement-coated cloth on the production line, and spray 5mm hair on the upper surface of the cement-coated cloth. Polyurethane foam;

[0039] 2) Lay the rock wool on the cement-coated cloth sprayed with foamed polyurethane;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com