PP (Propene Polymer) honeycomb board material for automobile spare tyre cover plate

A technology of automobile spare tire cover and honeycomb panel, which is applied to vehicle parts, film/sheet without carrier, synthetic resin layered products, etc. It can solve the problems of easy deformation of paper honeycomb, short service life, insufficient strength, etc., and achieve Fast drying, improved mechanical properties, high heat resistance and high cohesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

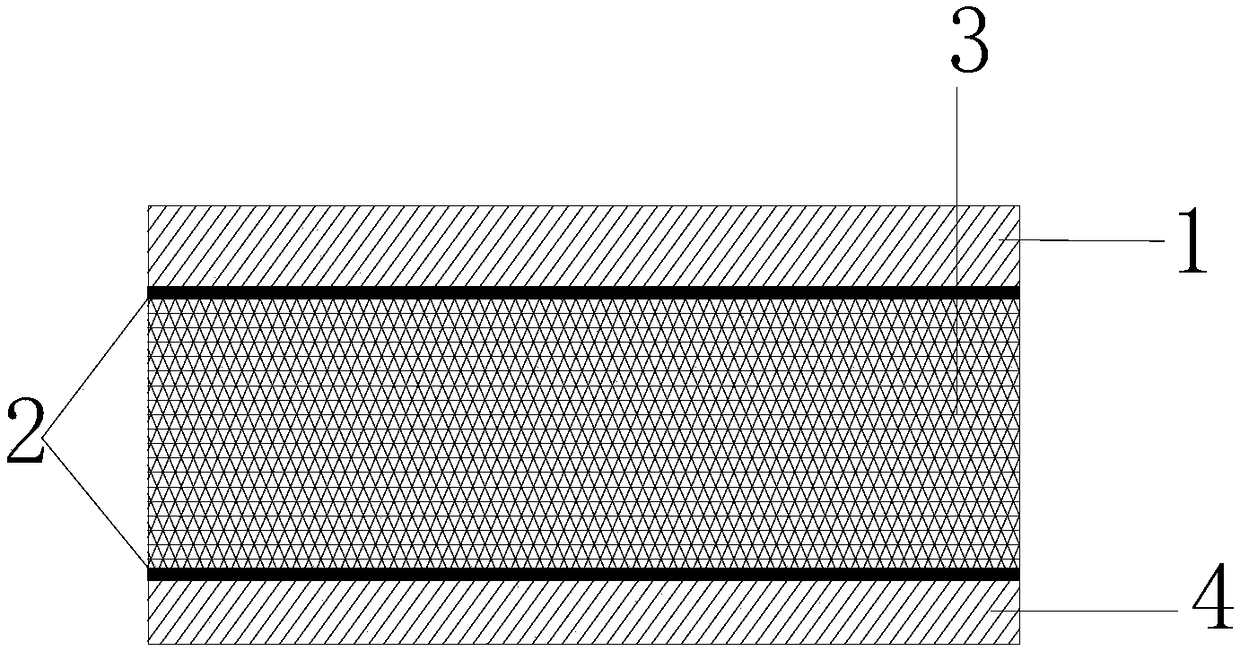

[0040] The PP honeycomb panel material for the automobile spare tire cover plate of the present embodiment comprises a surface layer 1, a bottom layer 4 and a polypropylene honeycomb core layer 3 arranged between the surface layer 1 and the bottom layer 4 and the surface layer 1, the polypropylene honeycomb core Layer 3 and bottom layer 4 are bonded as one hot-melt adhesive film layer 2, the surface layer 1 and bottom layer 4 are glass fiber materials, and the hot-melt adhesive film layer 2 raw materials include by weight:

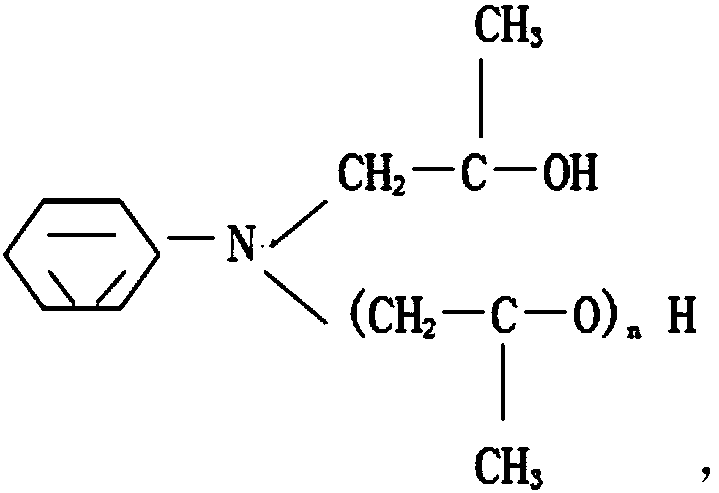

[0041] 25 ethylene-vinyl acetate copolymers, 5 parts 1,2-benzisothiazolin-3-one, 6 parts butyl rubber, 5 parts polymaleic anhydride, 10 parts 2,6-di-tert-butyl-p-cresol , 3 parts of filler, 5 parts of (2,3-dimethyl) dibutylene triamine, 5 parts of petroleum resin, 6 parts of diphenylmethane diisocyanate, 3 parts of 4,6-bis(dodecylthiomethyl )-O-cresol, 4 parts of N-methylol acrylamide, 1 part of N.N-dihydroxy (diisopropyl) aniline, 1 part of ultraviolet ab...

Embodiment 2

[0051] The PP honeycomb panel material for the automobile spare tire cover plate of the present embodiment comprises a surface layer 1, a bottom layer 4 and a polypropylene honeycomb core layer 3 arranged between the surface layer 1 and the bottom layer 4 and the surface layer 1, the polypropylene honeycomb core Layer 3 and bottom layer 4 are bonded as one hot-melt adhesive film layer 2, the surface layer 1 and bottom layer 4 are glass fiber materials, and the hot-melt adhesive film layer 2 raw materials include by weight:

[0052] 32 ethylene-vinyl acetate copolymers, 8 parts 1,2-benzisothiazolin-3-one, 10 parts butyl rubber, 10 parts polymaleic anhydride, 15 parts 2,6-di-tert-butyl-p-cresol , 8 parts of filler, 10 parts of (2,3-dimethyl) dibutylene triamine, 10 parts of petroleum resin, 9 parts of diphenylmethane diisocyanate, 6 parts of 4,6-bis(dodecylthiomethyl )-O-cresol, 8 parts of N-methylolacrylamide, 3 parts of N.N-dihydroxy (diisopropyl) aniline, 3 parts of ultraviol...

Embodiment 3

[0062] The PP honeycomb panel material for the automobile spare tire cover plate of the present embodiment comprises a surface layer 1, a bottom layer 4 and a polypropylene honeycomb core layer 3 arranged between the surface layer 1 and the bottom layer 4 and the surface layer 1, the polypropylene honeycomb core Layer 3 and bottom layer 4 are bonded as one hot-melt adhesive film layer 2, the surface layer 1 and bottom layer 4 are glass fiber materials, and the hot-melt adhesive film layer 2 raw materials include by weight:

[0063] 25 ethylene-vinyl acetate copolymers, 8 parts 1,2-benzisothiazolin-3-one, 6 parts butyl rubber, 10 parts polymaleic anhydride, 10 parts 2,6-di-tert-butyl-p-cresol , 8 parts of filler, 5 parts of (2,3-dimethyl) dibutylene triamine, 10 parts of petroleum resin, 6 parts of diphenylmethane diisocyanate, 6 parts of 4,6-bis(dodecylthiomethyl )-O-cresol, 4 parts of N-methylol acrylamide, 3 parts of N.N-dihydroxy (diisopropyl) aniline, 1 part of ultraviolet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com