Refining method of methyl chloroformate

A technology of methyl chloroformate and a purification method, which is applied in the field of purification of methyl chloroformate, can solve the problems of long reaction time, low material conversion rate, and many by-products, etc., so as to improve the reaction progress, improve economic benefits and save energy. The effect of synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

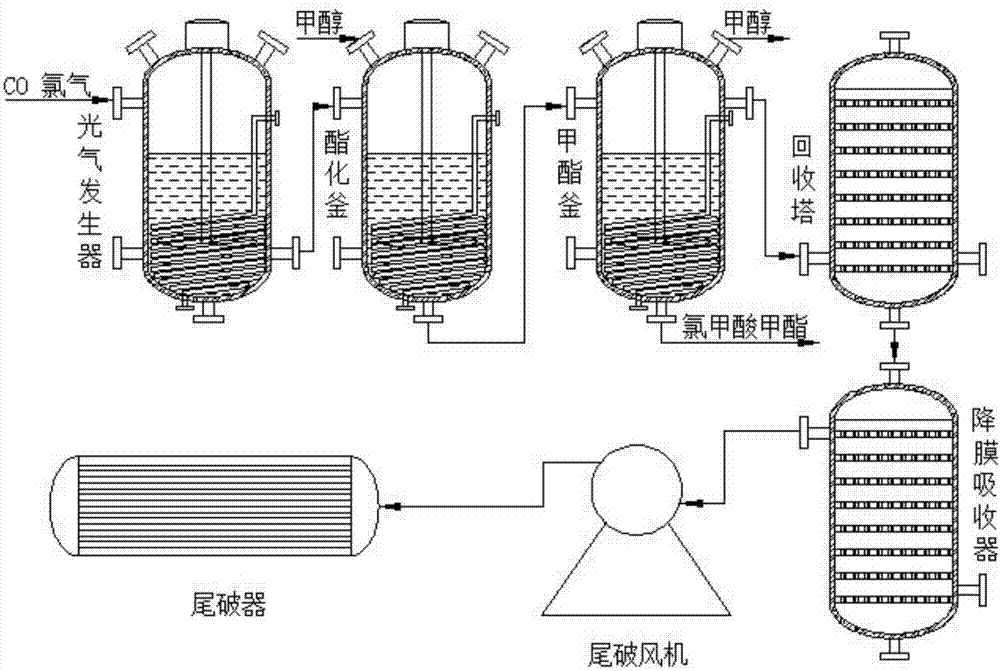

[0026] see figure 1 Shown, the technical scheme that the present invention adopts is: a kind of refining method of methyl chloroformate, the concrete of the refining method of described methyl chloroformate comprises the following steps:

[0027] (1). Synthesis: Pass CO and chlorine gas into the interior of the phosgene generator according to a certain molar ratio, and use the catalytic activity of the catalyst inside the phosgene generator to react and synthesize phosgene, and the synthesized phosgene is transferred to the ester chemical tower;

[0028] (2). Esterification: Set the shell-side refrigerant of the esterification tower to control the temperature in the esterification tower, and pass the generated phosgene and methanol into the esterification tower according to a fixed molar ratio to carry out the esterification reaction of gas-liquid bubbling and Alcoholysis of acid chlorides to synthesize methyl chloroformate;

[0029] (3). Refining: The mixed liquid phase of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com