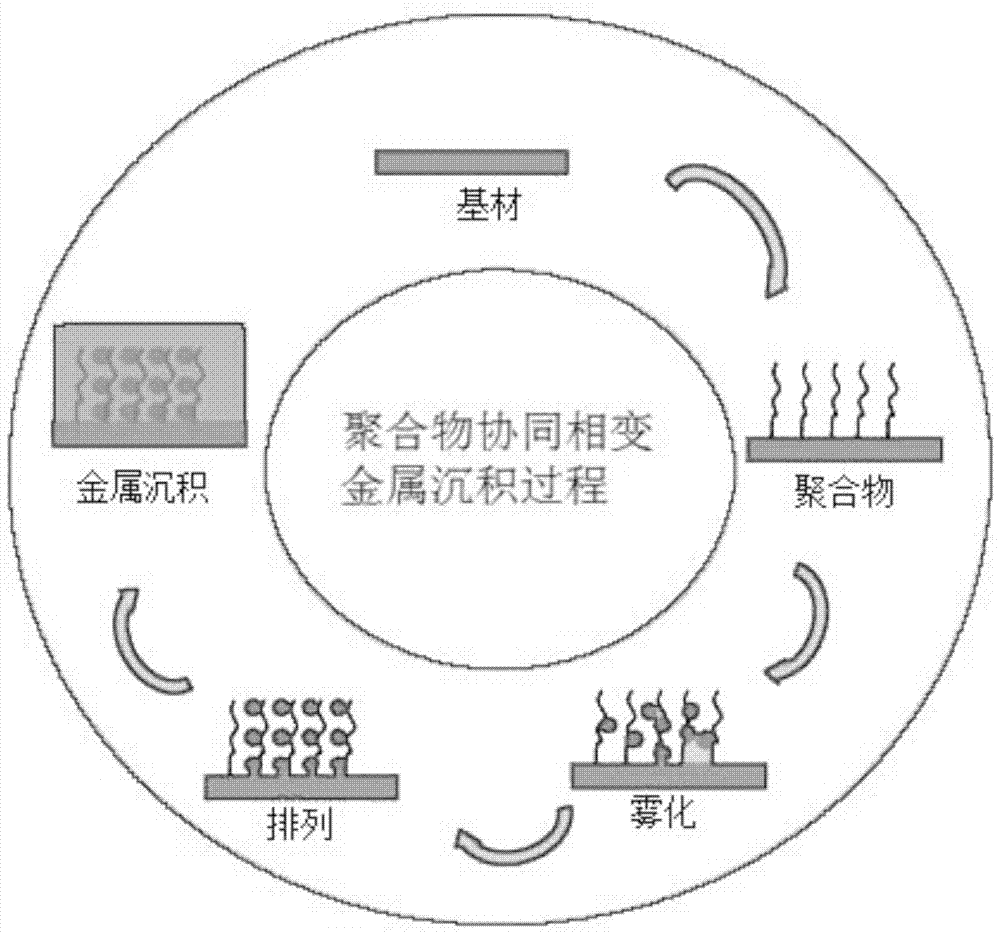

Method for depositing nano-alloy film layer with phase inversion technology

A nano-alloy and phase transformation technology, applied in the field of surface treatment, can solve the problems of anti-corrosion effect, poor surface gloss, high environmental requirements, unstable reagents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

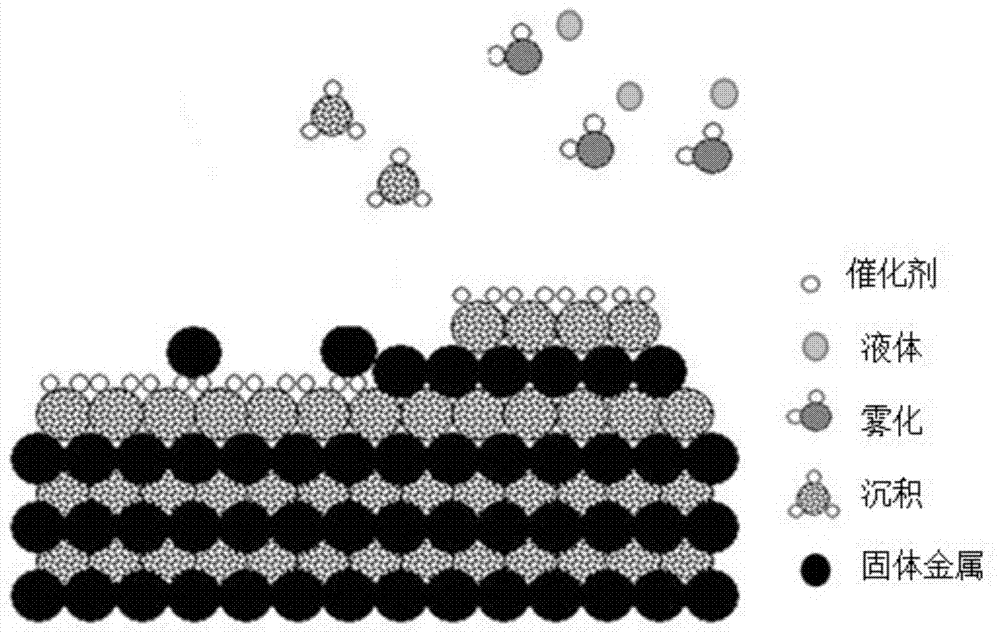

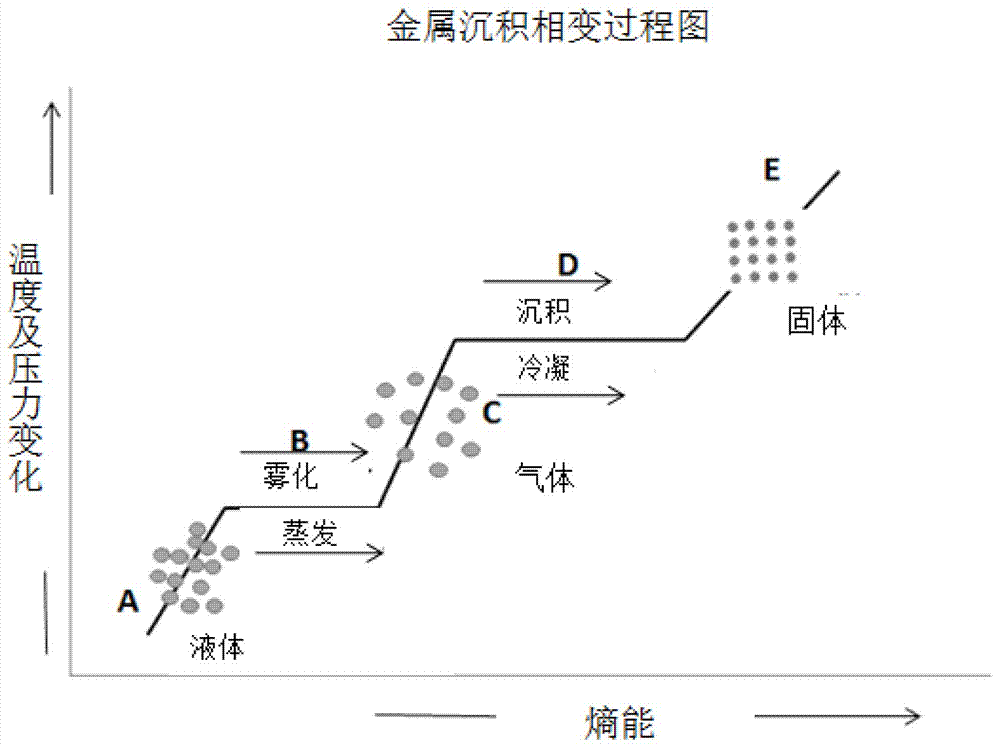

Method used

Image

Examples

Embodiment 1

[0033] (1) Catalyst preparation: take niobium chloride 0.2g, potassium permanganate 5g, mass fraction is 5% dilute hydrochloric acid 6ml, 90 milliliters of water

[0034] (2) Phase inversion alloy reactant preparation: 2g nickel chloride and 1g cobalt chloride solid are mixed and dissolved in 100ml water to obtain a solution containing nickel ions and cobalt ions; the configuration method of the reducing agent is: sodium hypophosphite 2.5 g, 0.5g of citric acid, 0.6g of sodium citrate, and 0.2ml of hydrazine hydrate were dissolved in 100ml of water, and stirred evenly.

[0035] (3) Clean the ABS base material with a hydrocarbon solution at 60°C and dry it, then coat the ABS base material with a layer of water-based polyurethane polymer, and then use a spray gun to uniformly spray the catalyst in (1) under a pressure of 90 psi Spray on the surface of the polymer, and then use a spray gun to atomize and spray the liquid containing nickel ions and cobalt ions on the surface of th...

Embodiment 2

[0045] (1) catalyst preparation: take niobium chloride 0.3g, potassium permanganate 8g, mass fraction is 5% dilute hydrochloric acid 10ml, 85 milliliters of water

[0046] (2) Phase inversion alloy reactant preparation: 2.0g nickel chloride and 1.0g cobalt chloride solid are mixed and dissolved in 100ml water to obtain a solution containing nickel ions and cobalt ions; the configuration method of the reducing agent is: hypophosphorous acid Dissolve 2.6g of sodium, 0.6g of citric acid, 0.7g of sodium citrate, and 0.3ml of hydrazine hydrate in 100ml of water, and stir well.

[0047] (3) Clean the ceramic substrate with a hydrocarbon solution at 60°C and dry it, then coat a layer of water-based polyurethane polymer on the ABS substrate, and then use a spray gun to uniformly spray the catalyst in (1) under a pressure of 90 psi Spray on the surface of the polymer, and then use a spray gun to atomize and spray the liquid containing nickel ions and cobalt ions on the surface of the p...

Embodiment 3

[0052] (1) Catalyst preparation: weigh 0.5 g of niobium chloride, 10 g of potassium permanganate, 10 ml of dilute hydrochloric acid with a mass fraction of 5%, and 80 ml of water.

[0053] (2) Phase inversion alloy reactant preparation: 2.0g nickel chloride and 1.2g cobalt chloride solid are mixed and dissolved in 100ml water to obtain a solution containing nickel ions and cobalt ions; the configuration method of the reducing agent is: hypophosphorous acid Dissolve 2.5g of sodium, 0.5g of citric acid, 0.6g of sodium citrate, and 0.2ml of hydrazine hydrate in 100ml of water, and stir well.

[0054] (3) Clean the glass substrate with a hydrocarbon solution at 60°C and dry it, then coat the glass substrate with a layer of water-based polyurethane polymer, and then use a spray gun to uniformly spray the catalyst in (1) under a pressure of 90 psi Spray on the surface of the polymer, and then use a spray gun to atomize and spray the liquid containing nickel ions and cobalt ions on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com