Preparation method of stretchable crystalline semiconductor nanowire based on linear design and guidance of planar nanowire

A nanowire and semiconductor technology, which is applied in the production field of spring structure crystal nanowires, can solve the problems that the existing technology is not very good, and achieve the effects of facilitating integration and use, and improving device characteristics and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

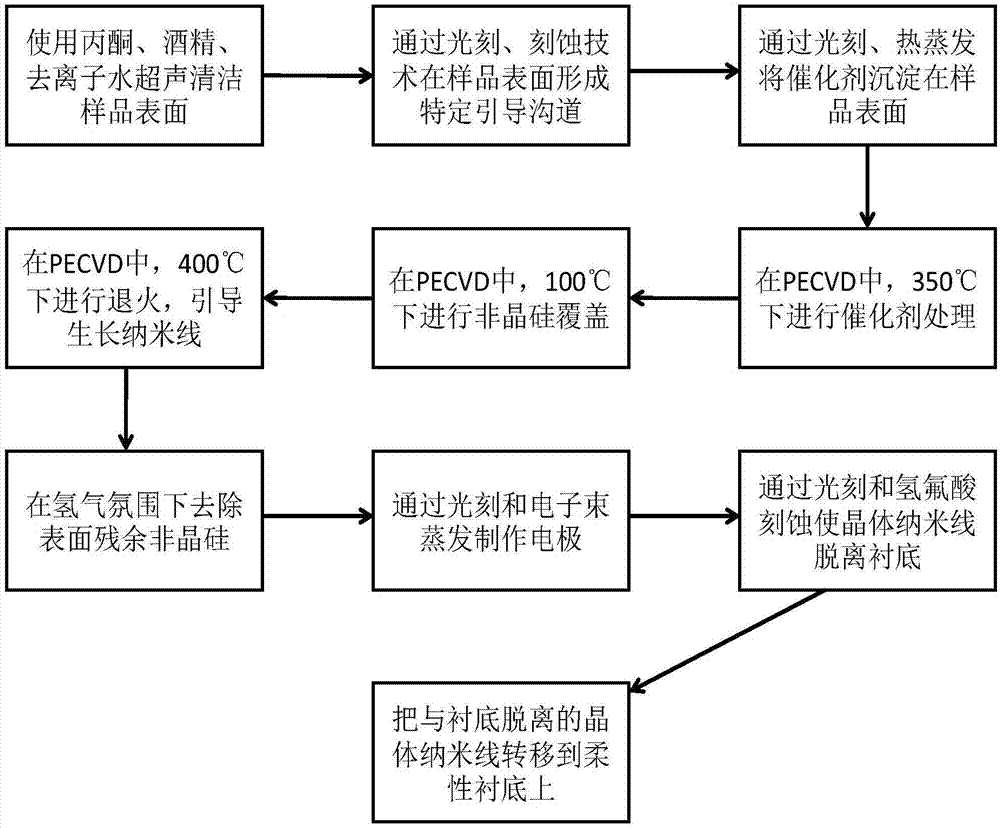

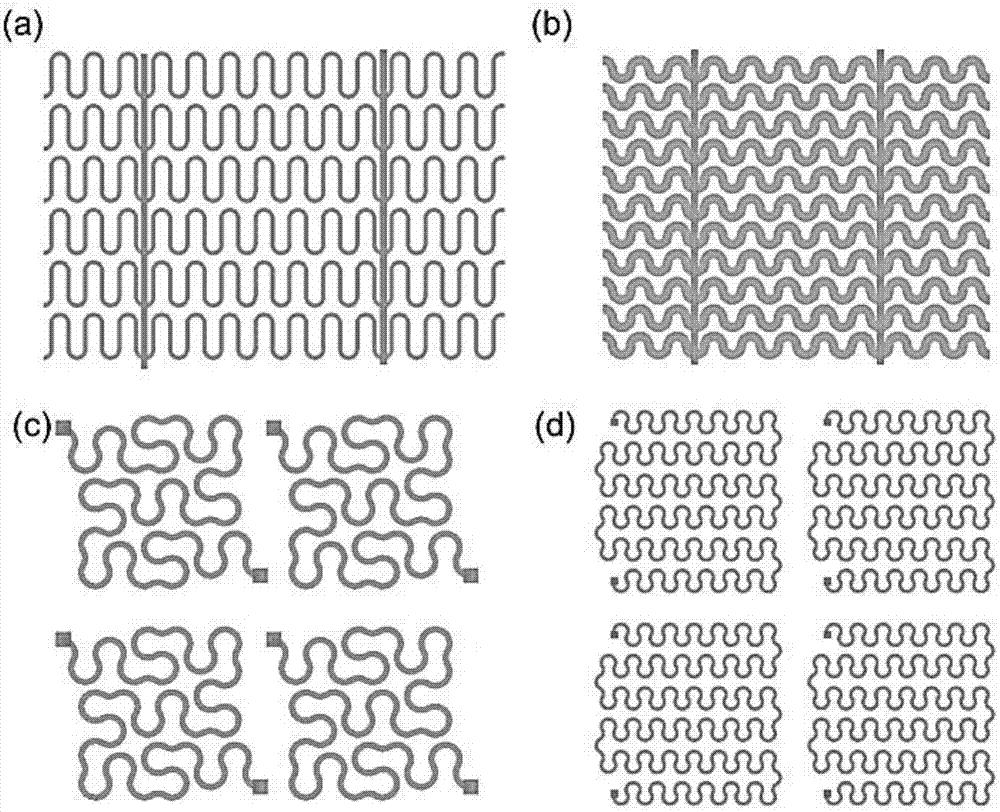

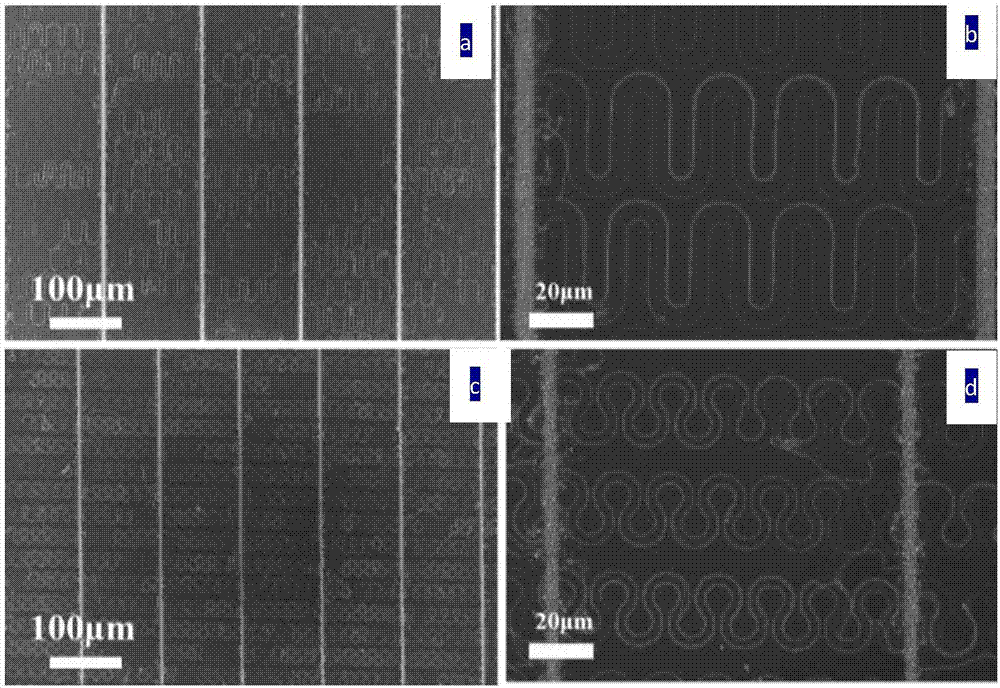

[0030] In order to make the objectives, technical solutions, functions and advantages of the present invention more clear, the following will further explain the present invention in detail with reference to specific examples. Flow chart attached figure 1 Shown. A linear design and guided growth technology based on planar nanowires realizes a preparation method of crystalline semiconductor (including silicon, germanium, etc.) stretchable electronic devices. Using conventional photolithography, etching techniques, or other template and surface processing techniques, a guide step with a specific shape is made on a glass or crystalline silicon substrate, and an amorphous thin film (using amorphous silicon, amorphous germanium and other amorphous silicon Crystalline inorganic semiconductor materials) are used as precursors, using metal (indium, tin, gallium, bismuth, etc.) catalytic particles to absorb amorphous films, and in the process of guiding the movement of the steps, the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com