Bioactive peptides extracted from galliformes phasianidae animals, and extraction method of bioactive peptides

A technology of biologically active peptides and active peptides, applied in the field of protein, can solve the problems of waste of raw materials, bitterness and fishy smell, low product yield, long enzymatic hydrolysis time, etc., and achieve the effects of improving production efficiency, low molecular weight, and easy absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: A kind of extraction method of quail active peptide

[0032] Include the following steps:

[0033] 1. Pretreatment

[0034] Slaughter the quail, remove the hair, remove the viscera and fat, clean it, put it into the enzymatic hydrolysis reaction tank, add drinking water according to the weight ratio of quail to drinking water 1:1.5, and cook at 100°C under normal pressure for 2 hours until the quail is cooked. Cool to about 50°C, add lipase (weight ratio of quail to lipase: 1:0.025) and stir at 47°C for degreasing treatment for 2 hours. Rapidly raise the temperature to 100°C at a heating rate of 10°C / min, and keep stirring for 10 minutes. Cool to about 50°C.

[0035] 2. Enzymolysis

[0036] Add the above cooling liquid to the compound enzyme (the weight of quail and compound enzyme is 1:0.008), stir the enzymolysis at 58°C for 3 hours, rapidly raise the temperature to 100°C at a heating rate of 10°C / min, stir and keep it for 10 minutes, and separate th...

Embodiment 2

[0048] Embodiment 2: A kind of extraction method of partridge active peptide

[0049] Include the following steps:

[0050] 1. Pretreatment

[0051] Slaughter the partridge and remove the hair, remove the viscera and fat, clean it, put it into the enzymatic hydrolysis reaction tank, add drinking water according to the weight ratio of the partridge to drinking water 1:1.5, and cook at 100°C for 2 hours under normal pressure until the partridge is cooked. . Cool to about 50°C, add lipase (weight ratio of partridge to lipase: 1:0.025) and stir at 50°C for degreasing treatment for 2 hours. Rapidly raise the temperature to 100°C at a heating rate of 10°C / min, and keep stirring for 10 minutes. Cool to about 50°C.

[0052] 2. Enzyme hydrolysis

[0053] Add the above-mentioned cooling liquid to the compound enzyme (the weight of partridge and compound enzyme is 1:0.008), and stir the enzymolysis at 56°C for 3 hours. Rapidly raise the temperature to 100°C at a heating rate of 10°...

Embodiment 3

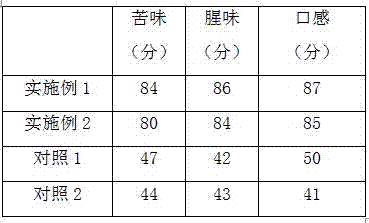

[0064] Embodiment 3 sensory evaluation experiment

[0065] Using the method of anonymous scoring, 9 experts with experience in active peptide tasting and 50 ordinary consumers were invited to form an evaluation team to evaluate the bitterness, fishy smell, and taste of the product. The closer to the best features of the product, the best features of each indicator are:

[0066] Bitterness: no bitterness;

[0067] Fishy smell: no fishy smell

[0068] Taste: strong umami taste, no peculiar smell;

[0069] The products evaluated were the quail active peptide extracted in Example 1, the partridge active peptide extracted in Example 2, the quail active peptide extracted by the method of the prior art (control 1), and the partridge active peptide extracted by the method of the prior art. Active peptide (control 2).

[0070] The extraction method used in comparison 1 and comparison 2 is the extraction method described in Chinese patent CN1523117A, and the raw materials are replac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com