Preparation method of caramel sunflower seeds

A technology of sunflower seeds and caramelization, which is applied in the field of preparation of caramelized sunflower seeds, can solve the problems of not being able to meet the needs of the audience, the single sweetness of caramelized sunflower seeds, and the unbalanced appearance and taste of caramelized sunflower seeds. Mature methods and process equipment, bright luster, and excellent market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

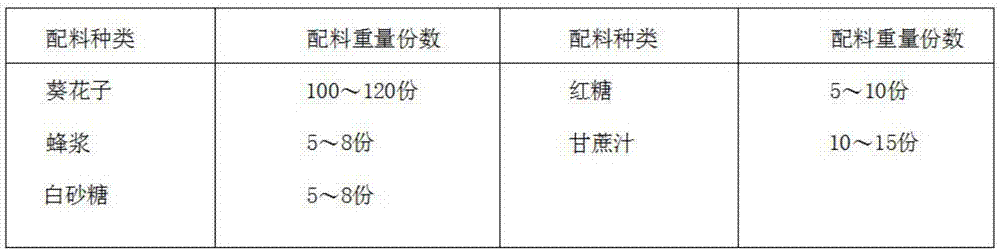

[0021] see Figure 1-2 As shown, the present invention provides a kind of technical scheme: a kind of preparation method of caramelized sunflower seeds, the preparation method of described caramelized sunflower seeds specifically comprises the following steps:

[0022] 1). Washing: Put 100 parts of sunflower seeds that have been stripped into a warm water basin at 60°C, remove unqualified sunflower seeds floating on the hot water surface, soak for 30 minutes, stir and wash the sunflower seeds;

[0023] 2). Drying: Dry the washed sunflower seeds in the open air and put them in the oven. Set the drying temperature in the oven to 80°C and dry for 30 minutes. Take it out and cool it;

[0024] 3). Dipping material: Pour the dried sunflower seeds into the pot, add 45 parts of brown sugar, 10 parts of bee jelly, 15 parts of white sugar, 15 parts of sugarcane juice, 5 parts of tangerine peel powder, and 3 parts of cinnamon powder in parts by weight , 5 parts of pepper, 5 parts of sta...

Embodiment 2

[0027] see Figure 1-2 As shown, the present invention provides a kind of technical scheme: a kind of preparation method of caramelized sunflower seeds, the preparation method of described caramelized sunflower seeds specifically comprises the following steps:

[0028] 1). Washing: Put 100 parts of sunflower seeds that have been stripped into a warm water basin at 50°C, remove unqualified sunflower seeds floating on the hot water surface, soak for 55 minutes, stir and wash the sunflower seeds;

[0029] 2). Drying: Dry the washed sunflower seeds in the open air and put them in the oven. Set the drying temperature in the oven to 75°C and dry for 55 minutes. Take it out and cool it;

[0030] 3). Dipping material: Pour the dried sunflower seeds into the pot, add 30-45 parts of brown sugar, 15 parts of bee jelly, 15 parts of white sugar, 20 parts of sugarcane juice, 3 parts of tangerine peel powder, and cinnamon powder in parts by weight. 3 parts, 2 parts of pepper, 5 parts of sta...

Embodiment 3

[0033] see Figure 1-2 As shown, the present invention provides a kind of technical scheme: a kind of preparation method of caramelized sunflower seeds, the preparation method of described caramelized sunflower seeds specifically comprises the following steps:

[0034] 1). Washing: Put 120 parts of sunflower seeds that have been stripped into a warm water basin at 45°C, remove unqualified sunflower seeds floating on the hot water surface, soak for 60 minutes, stir and wash the sunflower seeds;

[0035] 2). Drying: Dry the washed sunflower seeds in the open air and put them in the oven. Set the drying temperature in the oven to 70°C and dry for 45 minutes. Take it out and cool it;

[0036] 3). Dipping material: pour the dried sunflower seeds into the pot, add 35 parts of brown sugar, 13 parts of bee jelly, 10 parts of white sugar, 16 parts of sugarcane juice, 3 parts of tangerine peel powder, and 3 parts of cinnamon powder according to the parts by weight , 5 parts of pepper, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com