Device and method for treating refractory wastewater by coupling electrocatalytic membrane with three-dimensional electrode

A three-dimensional electrode, electrocatalytic membrane technology, applied in chemical instruments and methods, special compound water treatment, oxidized water/sewage treatment, etc. Application difficulties and other problems to achieve the effect of reducing energy consumption, reducing work pressure and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

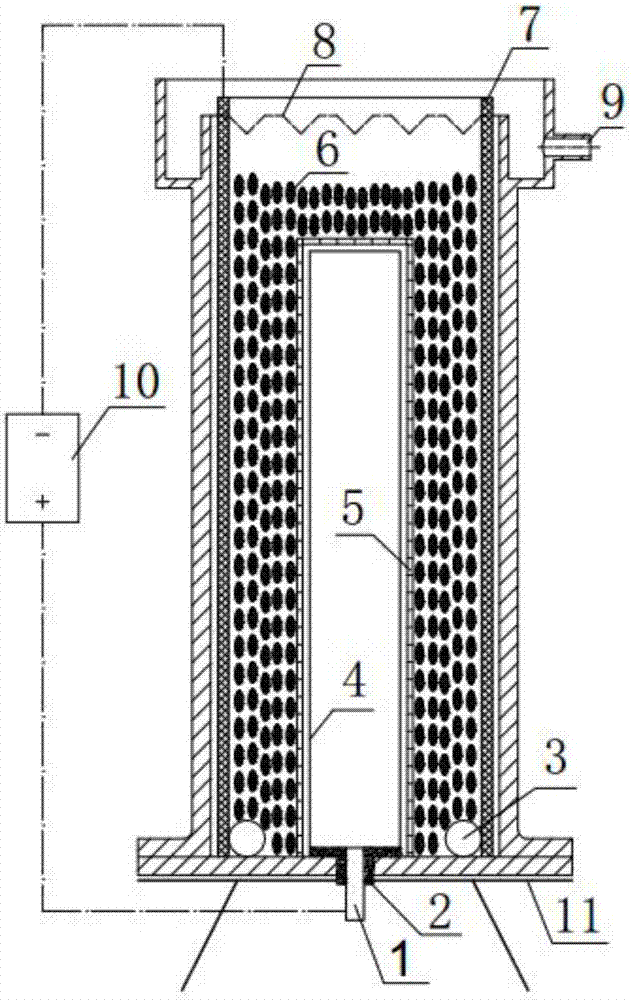

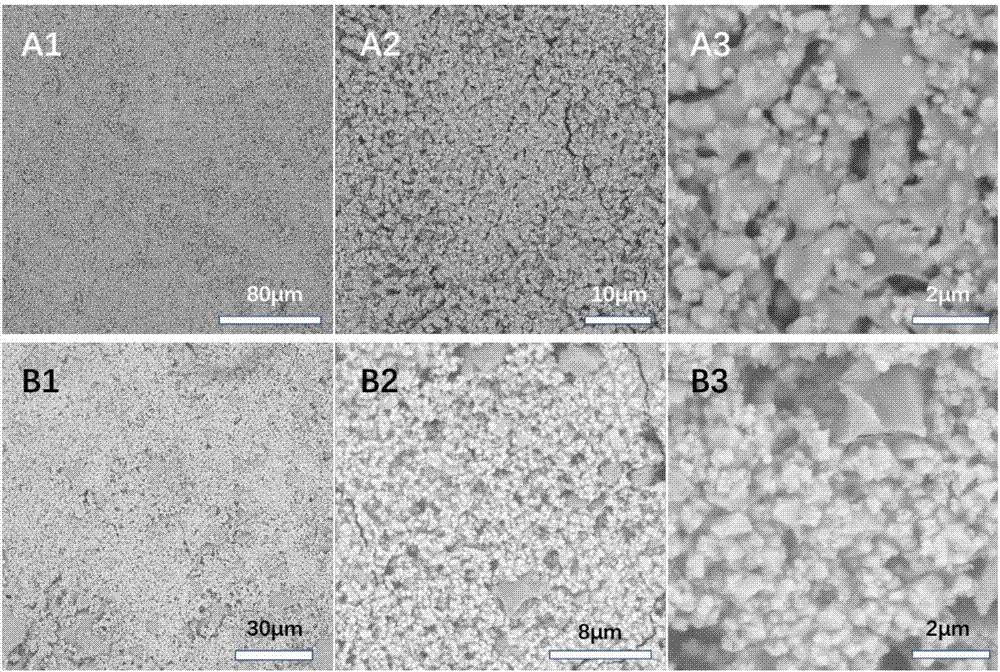

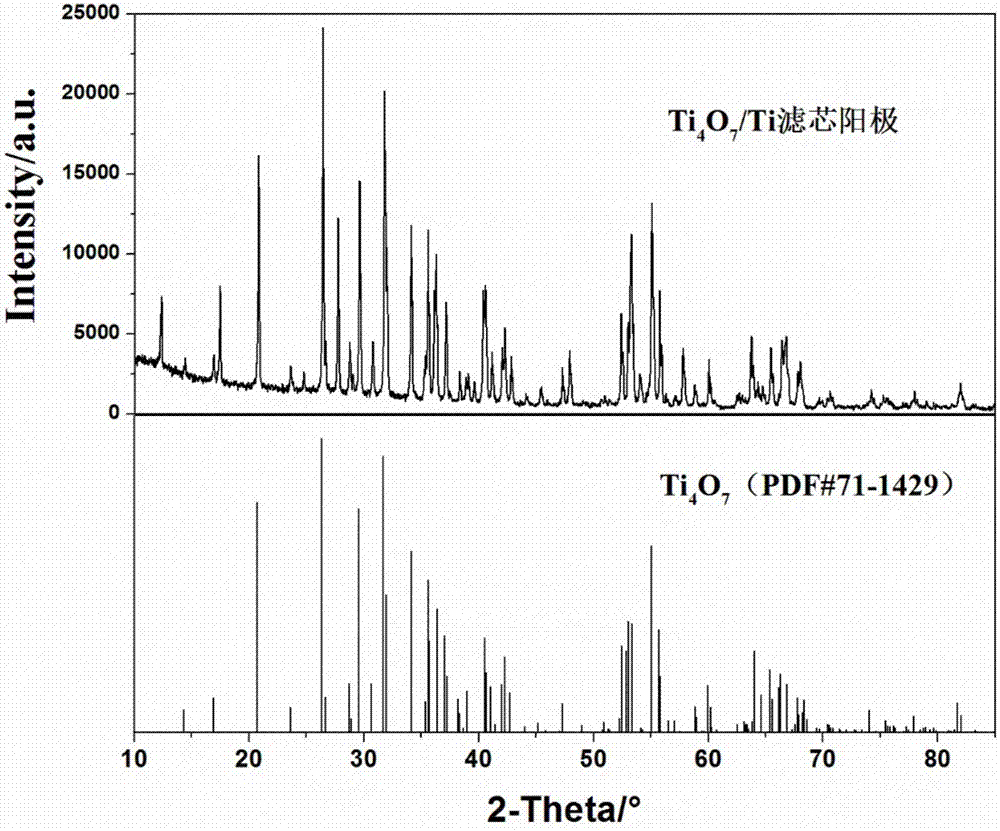

[0055] The embodiment of the present invention provides a device and method for coupling an electrocatalytic membrane and a three-dimensional electrode to treat refractory wastewater. The diagram of the reaction device is as follows figure 1 As shown, the device includes: Ti 4 o 7 / Ti filter anode 4, permeable screen 5, C@Fe 3 o 4 Particles 6, graphite felt cathode 7, aeration pipe 3, constant current and voltage stabilized power supply 10, water inlet 1, water outlet pipe 9, glue seal 2, overflow weir 8 and support 11.

[0056] The composition and structure of the device for coupling electrocatalytic membrane and three-dimensional electrode to treat refractory wastewater are as follows:

[0057] The overall device is cylindrical, from the inside to the outside are: Ti 4 o 7 / Ti filter anode 4, permeable screen 5, C@Fe 3 o 4 Particle 6, graphite felt cathode 7 and support 11; Open a through hole at the bottom of the device, Ti 4 o 7 The water inlet 1 of the anode 4 of...

Embodiment 2

[0087] This embodiment provides a device and method for coupling an electrocatalytic membrane with a three-dimensional electrode to treat refractory wastewater. The main treatment object of the device is refractory organic pollutants. Concentrated water) is used as the treatment target, and the device is used for treatment.

[0088] NF concentrated water was taken from a reclaimed water plant in Beijing, and its water quality indicators are shown in Table 1.

[0089] Table 1 Analysis table of NF concentrated water quality of a water plant in Beijing

[0090]

[0091] The device used is as described in Example 1, and will not be repeated here, and the device used can be referred to as an electrocatalytic oxidation device for short.

[0092] The electrocatalytic oxidation device treats NF concentrated water as follows:

[0093] The water inlet is at the center of the bottom of the device, and the NF concentrated water to be treated is positively pumped into the Ti through a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com