Dirt dispersion agent for ultra-high-rate operation of circulating cooling water

A scale inhibitor and dispersant, multi-rate technology, applied in the field of water treatment, can solve the problems of large amount of compounding, narrow water quality adaptation range and high use concentration, and achieve the effect of improving operating index and good scale inhibition and dispersion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of polyamino polyether group methylene phosphonic acid:

[0037] 1) Amino-terminated polyether and phosphorous acid are added to the reactor at a molar ratio of 1:4, and sulfuric acid with a mass fraction of phosphorous acid (calculated as sulfuric acid) of 7% and partially demineralized water are added;

[0038] 2) Keep the reaction temperature at about 45°C for 1 hour, raise the temperature to 100°C, condense and reflux, and slowly add formaldehyde dropwise to the solution for not less than 1 hour, and the molar ratio of amino-terminated polyether to formaldehyde is 1:5 ;

[0039] 3) After the dropwise addition of formaldehyde is completed, continue to heat and reflux for about 2 hours at a temperature not less than 105°C.

[0040] 4) Distill under reduced pressure, finally add a certain amount of demineralized water, and mix well to obtain a qualified liquid product.

Embodiment 2

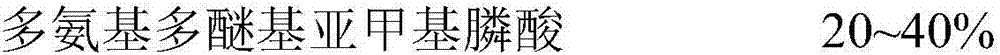

[0043] A scale inhibitor dispersant composition for ultra-high rate operation of circulating cooling water, the mass percentage of each component is composed of:

[0044]

[0045] The amino-terminated polyether used in the preparation of the polyamino polyether group methylene phosphonic acid is the amino-terminated polyether D2000.

Embodiment 3

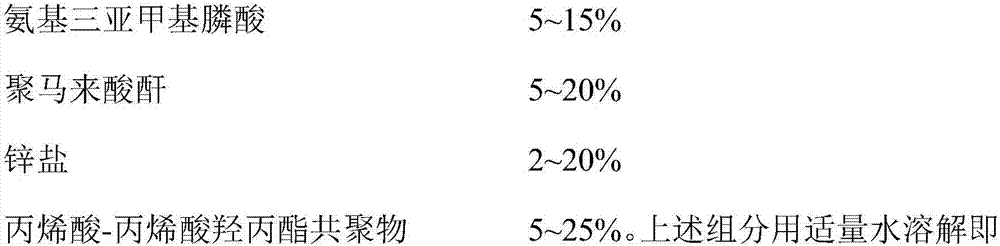

[0047] A scale inhibitor dispersant composition for ultra-high rate operation of circulating cooling water, the mass percentage of each component is composed of:

[0048]

[0049]The amino-terminated polyether used in the preparation of the polyamino-polyether-based methylene phosphonic acid is amino-terminated polyether D230.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com