A kind of extraction and separation method of ajoene in garlic

A separation method and technology of ajoene, which is applied in the field of extraction and separation of garlic ajoene, can solve problems such as difficulty in obtaining ajoene products, large consumption of ethanol and vegetable oil, difficult recovery and utilization of solvents, etc., and achieve high utilization rate, The effect of short production cycle and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

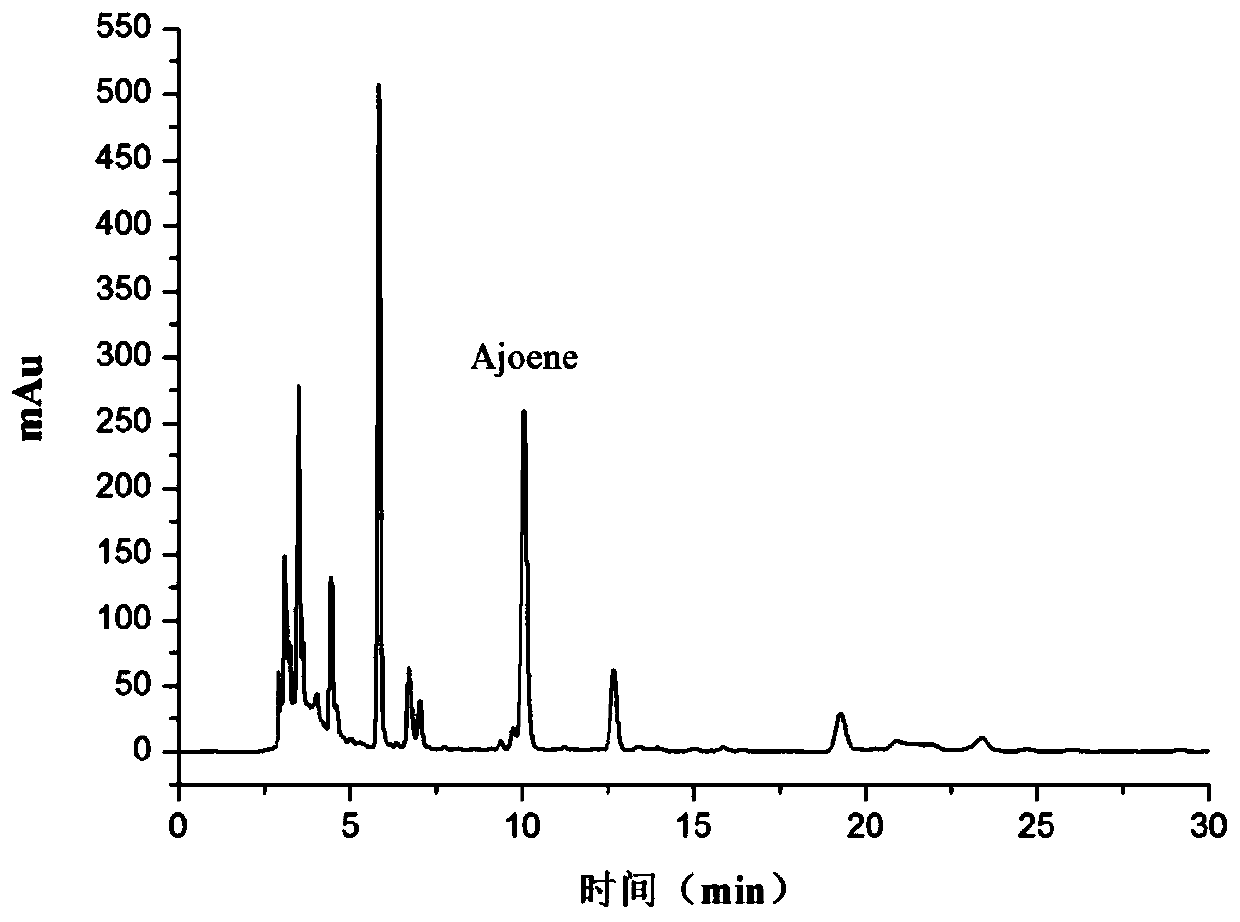

[0026] (1) Weigh 10 kg of pretreated Shandong garlic, pulverize with a grinder to a particle size of 1 mm, add 40L of 95% ethanol solution, and extract with ultrasonic vibration at room temperature for 1 hour. After the extraction is completed, filter with a bag, and the filtrate is concentrated under reduced pressure at 50-60℃ to remove the solvent. Concrete extract I. The recovered ethanol will be used for the next batch of extraction after inspection and meet the requirements, and the garlic residue will be used to extract polar components such as polysaccharides or to make feed;

[0027] (2) Put the extract I obtained in step (1) into the extraction kettle of the supercritical extraction device, using supercritical CO 2 Fluid extraction and separation. The extraction kettle is heated to 65°C and the pressure is increased to 40MPa, and the separation kettle I is heated to 50°C and the pressure is increased to 16MPa, and then cyclic extraction is started to control CO 2 The flo...

Embodiment 2

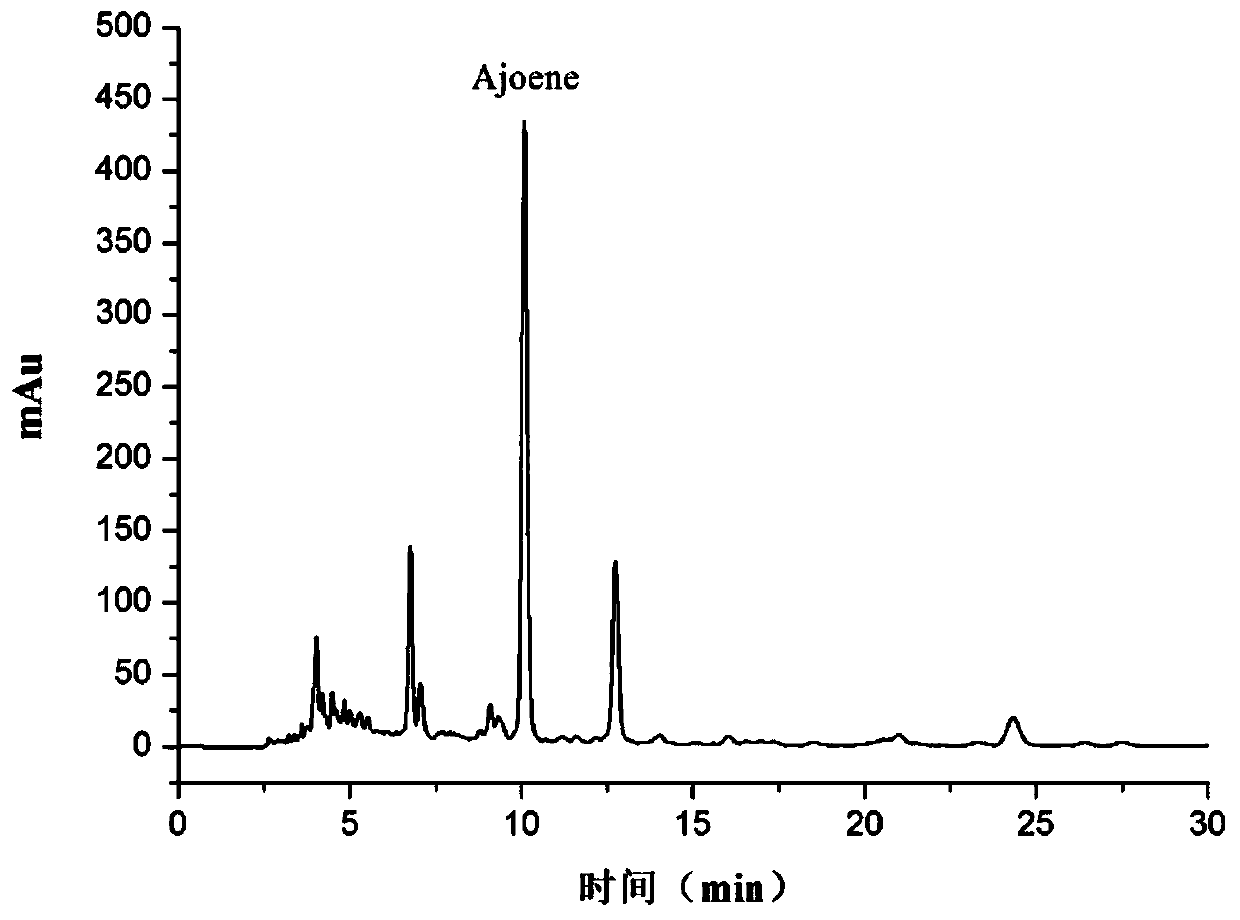

[0031] (1) Weigh 10 kg of pretreated Gansu garlic, pulverize with a grinder to a particle size of 0.2mm, add 20L of 95% ethanol solution, and extract with ultrasonic vibration at room temperature for 2 hours. After the extraction is completed, filter with a cloth bag, and the filtrate is concentrated and removed under reduced pressure at 50-60°C. The solvent is used to obtain extract II. The recovered ethanol will be used for the next batch of extraction after inspection and meet the requirements, and the garlic residue will be used to extract polar components such as polysaccharides or to make feed;

[0032] (2) Put the extract II obtained in step (1) into the extraction kettle of the supercritical extraction device, using supercritical CO 2 Fluid extraction and separation. The extraction kettle is heated to 75°C and the pressure is increased to 15MPa, and the separation kettle I is heated to 60°C and the pressure is increased to 20MPa, and then the cyclic extraction is started ...

Embodiment 3

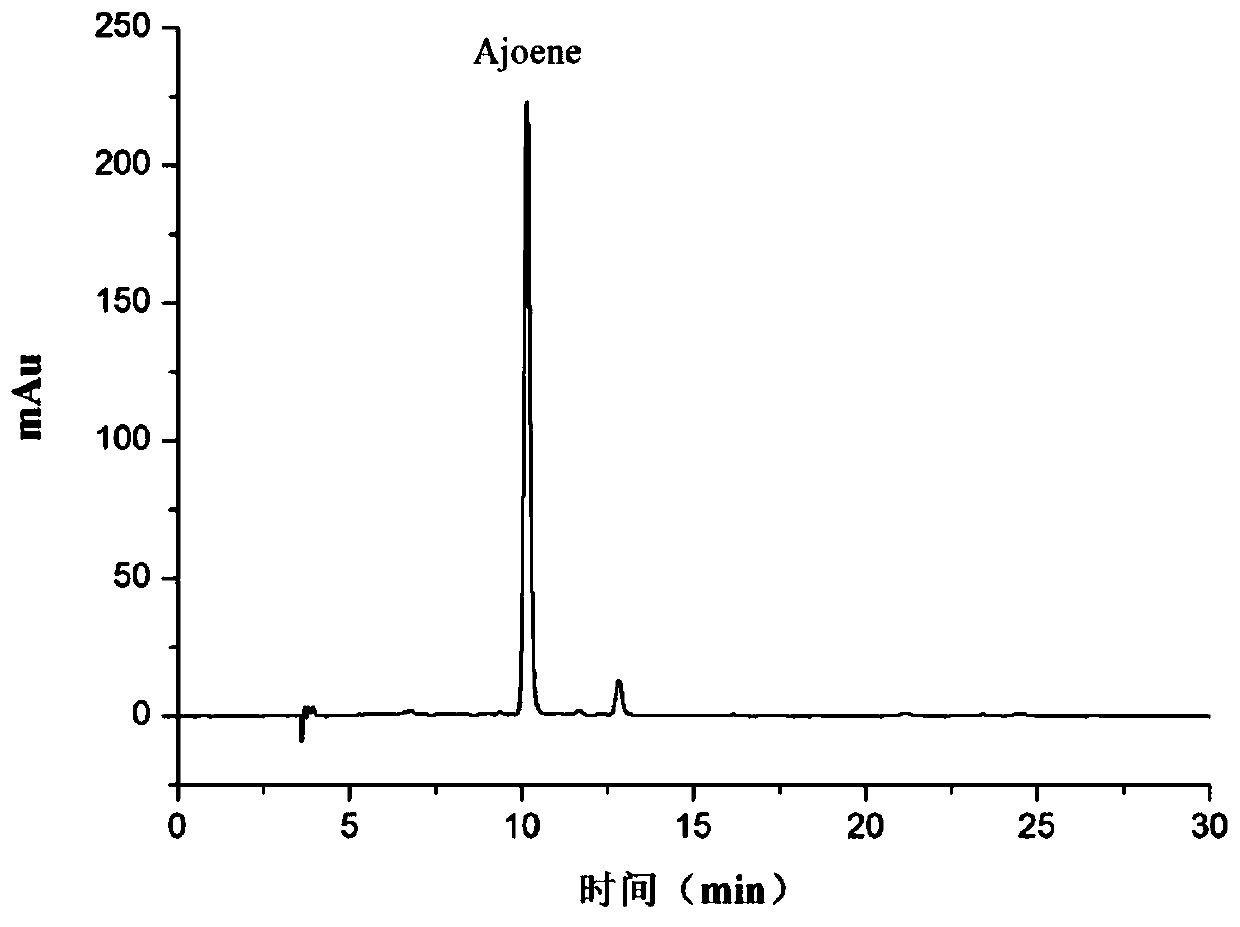

[0036] (1) Weigh 10Kg of the pretreated Yunnan garlic, pulverize it to a particle size of 2mm, add 80L 95% ethanol solution, and extract with ultrasonic vibration at room temperature for 0.5h. After the extraction is completed, filter with a cloth bag, and the filtrate is concentrated and removed under reduced pressure at 50-60℃. The solvent is used to obtain the extract III. The recovered ethanol will be used for the next batch of extraction after inspection and meet the requirements, and the garlic residue will be used to extract polar components such as polysaccharides or to make feed;

[0037] (2) Put the extract III obtained in step (1) into the extraction kettle of the supercritical extraction device, using supercritical CO 2 Fluid extraction and separation. The extraction kettle is heated to 35°C and the pressure is increased to 60MPa, and the separation kettle I is heated to 30°C and the pressure is increased to 9MPa, and then cyclic extraction is started to control CO 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com