Vinyl chloride polymerization reaction termination method

A technology of vinyl chloride polymerization and vinyl chloride monomer, which is applied in the field of vinyl chloride polymerization reaction termination, can solve the problems such as narrowing of use range, poor thermal stability improvement effect, inability to quickly terminate the thermal stability of vinyl chloride resin, etc. Termination effect, effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

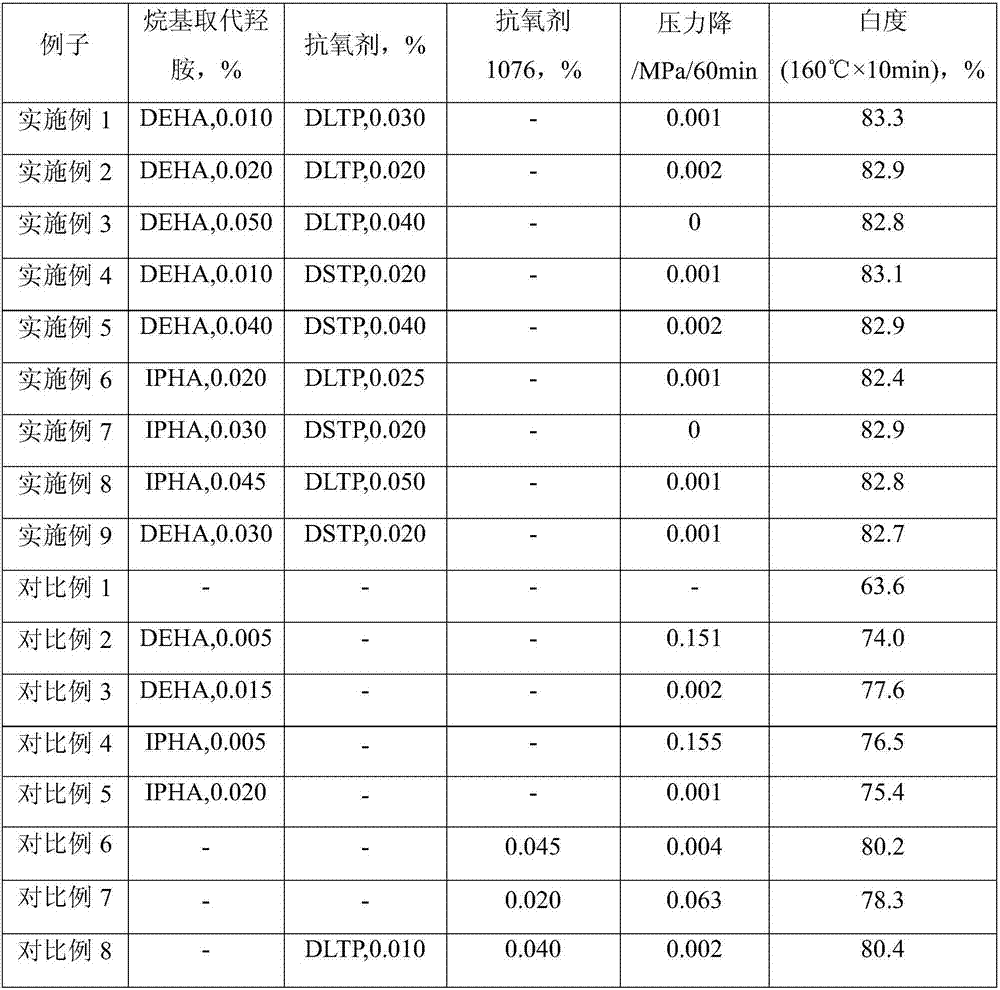

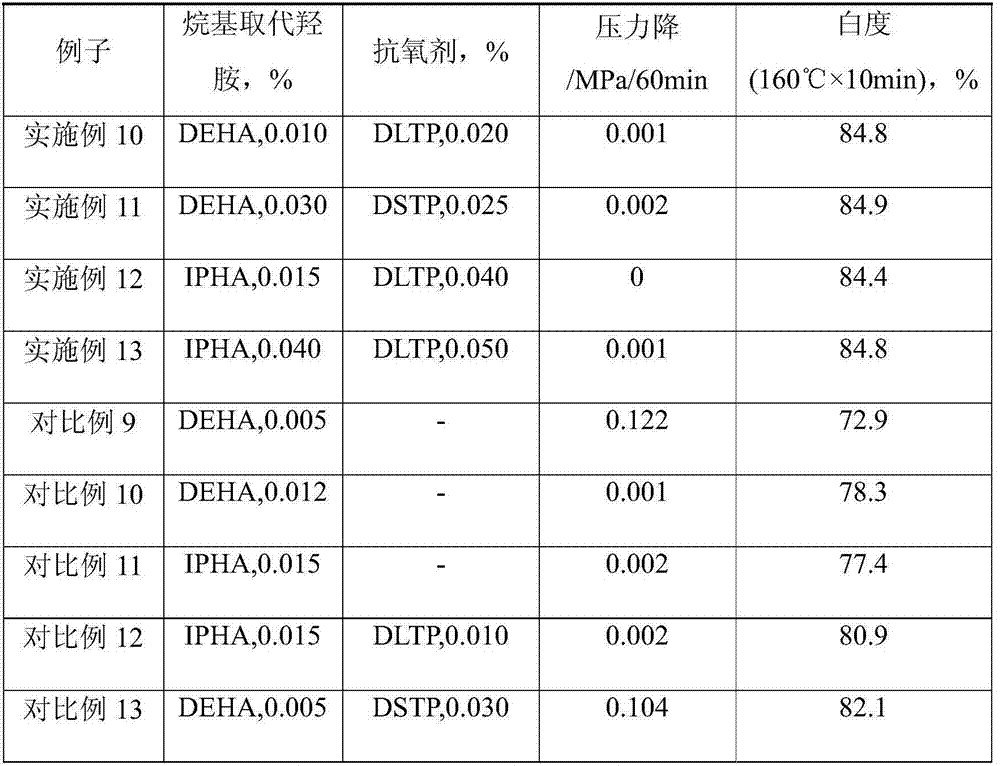

Examples

Embodiment 1

[0036] Add 2.4kg desalted water, 8.0g concentration of 5.0% polyvinyl alcohol 424H aqueous solution (KURARAY company product), 10.0g concentration of 3.0% hydroxypropyl methylcellulose in the 5L stainless steel pressure reactor equipped with two-layer double-leaf flat paddle Element E50 solution (Dow chemical products), 0.267g content 75% tert-butyl peroxyneodecanoate (TBPND, Akzo Nobel Tianjin company production) and 0.533g content 75% pivalate pivalate (TAPP, Akzo Nobel produced by Tianjin Company). Evacuate the pressure inside the kettle to below -0.090MPa, add 1.0kg of vinyl chloride monomer, start stirring, control the speed at 480rpm, stir and mix at room temperature for 10 minutes, then raise the temperature of the kettle to 62.2°C, and react after the temperature is stable Start timing, and add 22.0 g of 1% NG aqueous solution of formula quantity to kettle by plunger metering pump with 0.2 g / min flow rate. When the pressure drop in the kettle reached 0.10MPa, add 10.0...

Embodiment 2

[0042] The polymerization operation method is the same as that of Example 1, except that 50.0 g of 1.0% DEHA aqueous solution and 2.0 g of DLTP emulsion with an effective content of 20% are used to terminate the polymerization. The results are shown in Table 1.

Embodiment 3

[0044] The polymerization operation method is the same as in Example 1, except that 10.0 g of 1.0% DEHA aqueous solution and 1.0 g of 20% effective content of distearyl thiodipropionate (DSTP) emulsion are used to terminate the polymerization.

[0045] In this example, the preparation method of the DSTP emulsion is the same as that of the DLTP in Example 1, except that it needs to be heated up to 75°C, and then cooled to below 50°C. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com