A kind of manufacturing method of polymer material

A technology of high molecular polymers and manufacturing methods, applied in the field of high molecular polymer material manufacturing, can solve problems such as difficult to achieve micro-mixing, unproposed process flow, poor performance of blends, etc., and achieve good application value and production cost Low cost, reasonable process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

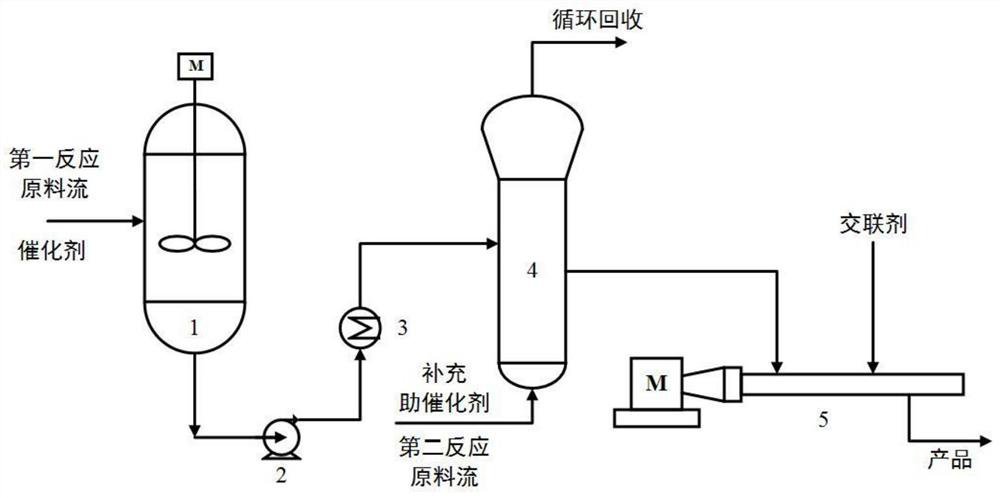

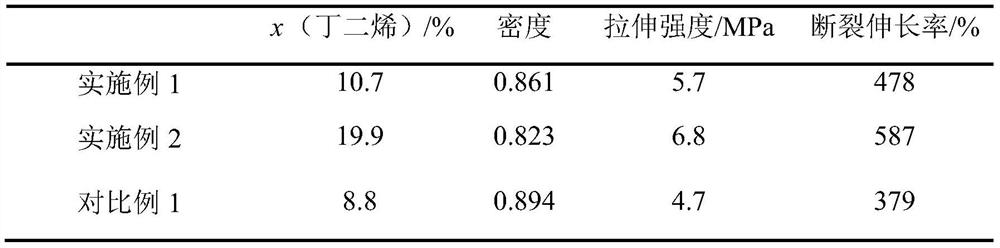

[0036] Such as figure 1 As shown, a manufacturing method of a high molecular polymer material is generated in two series reactors, with an output of 40,000 tons / year, and the weight distribution of the two reaction monomer units in the final product is 10:90.

[0037] S1, in the process described, the first reaction material consisting of monomer 1,3-butadiene and diluent is mixed with isopentane and Ziegler-Naturium composed of titanium tetrachloride and triethylaluminum The tower catalyst system (titanium / aluminum is 1:1000) enters the first reactor 1 (stirred tank reactor) together, the feed flow rate of the catalyst system is 1kg / h, the reaction temperature of the first reactor is 30°C, and the reaction pressure is 0.4Mpa, catalyst activity is 5000kg product / kg catalyst, 1,3-butadiene feed is 300kg / h, 1,3-butadiene concentration in reaction solution is 300kg1,3-butadiene / m 3 solvent. The reaction time is 72h. The 1,3-butadiene polymer accounts for 10% of the total mass ...

Embodiment 2

[0041] The operating conditions of the first reactor 1 and the second reactor 4 and the selection of materials in the stream are the same as in Example 1, and the output is also the same as 40,000 tons / year. The difference is that the different reaction polymerizations in the two reactors The monomer content is distributed among the products. In this embodiment, the distribution of butadiene units and ethylene units in the total mass of the final product is 20:80.

[0042] S1, the first reaction raw material stream: monomer 1,3-butadiene and diluent isopentane, Ziegler-Natta catalyst system (titanium / aluminum is 1 :1000) into the first reactor 1 together. The feed flow rate of the catalyst system is 1kg / h, the reaction temperature of the reactor is 30°C, the reaction pressure is 0.4Mpa, the catalyst activity is 5000kg product / kg catalyst, the feed rate of 1,3-butadiene is 300kg / h, and the reaction solution The concentration of 1,3-butadiene in is 300kg1,3-butadiene / m 3 solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com