Automotive wiper motor electrical contact grease composition and preparation method

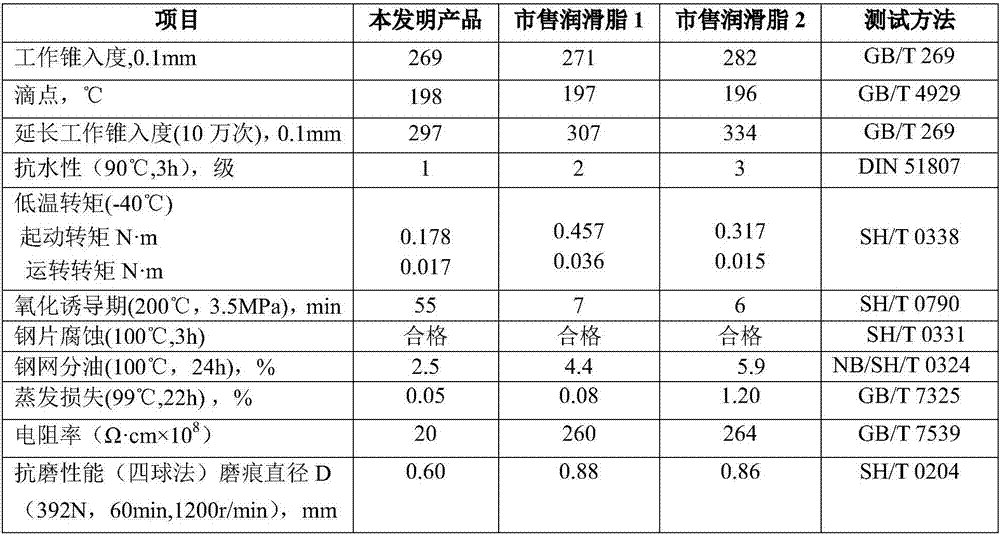

A grease composition and the technology of the composition, applied in the field of grease, can solve the problems of wear resistance, low oil separation rate, low evaporation loss, poor performance, poor lubrication, etc., and achieve small evaporation loss, low oil separation rate, resistance to Arc Prominent Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

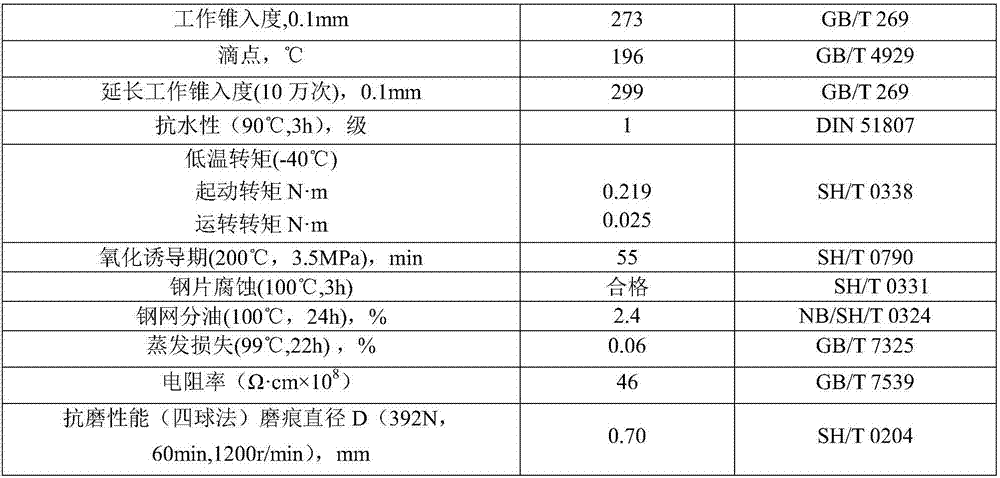

Embodiment 1

[0029] Embodiment 1: each component comprises by the total weight of composition:

[0030] (1) Base oil 84.97%;

[0031] (2) Thickener 11%;

[0032] (3) Antioxidant 1%;

[0033] (4) 0.03% rust inhibitor;

[0034] (5) Anti-wear agent 1%;

[0035] (6) Conductive agent 1%;

[0036] (7) Filler 1%.

[0037] With 110 grams of 12 hydroxy fatty acid lithium soap and 356g of PAO (the freezing point is -40 ℃, the viscosity at 100 ℃ is 8mm 2 / s) Put it into the reactor and heat it up to 85°C, add 178g of PAO for dehydration; after completing the heating and dehydration, continue to heat up to 200°C, then use 178g of PAO to cool in the reactor, and the temperature after cooling is controlled at 170°C Keep the temperature for 20 minutes, add the remaining 178g of PAO, after the temperature drops to 80°C, add 10 grams of 4,4-methylene bis-2,6-di-tert-butyl p-cresol, 0.3 grams of benzotriazole, 10 grams of diphosphite n-butyl ester, 10 grams of conductive polyaniline and 10 grams of p...

Embodiment 2

[0041] Embodiment 2: each component comprises by the total weight of composition:

[0042] (1) Base oil 77.97%;

[0043] (2) Thickener 13.0%;

[0044] (3) Antioxidant 1%;

[0045] (4) 0.03% rust inhibitor;

[0046] (5) Anti-wear agent 2%;

[0047] (6) Conductive agent 3%;

[0048] (7) Filler 3%.

[0049] Mix 130 grams of lithium stearate soap and 348 grams of perfluoropolyether (the freezing point is -42°C, the viscosity at 100°C is 6mm 2 / s) Put it into the reactor and heat it up to 95°C, add 174g of perfluoropolyether for dehydration; The temperature was controlled at 190°C for 10 minutes, and the remaining 174g of perfluoropolyether was added. After the temperature dropped to 80°C, 10g of 2,6-di-tert-butyl-p-cresol, 0.3g of heptadecenyl imidazoline, and 20g of phosphoric acid were added. Tricresyl ester, 30 grams of graphite and 30 grams of melamine cyanurate salt are subjected to post-treatment processes such as grinding and degassing to obtain the electrical contac...

Embodiment 3

[0053]Embodiment 3: each component comprises by the total weight of composition:

[0054] (1) Base oil 84.47%;

[0055] (2) Thickener 9%;

[0056] (3) Antioxidant 1%;

[0057] (4) 0.03% rust inhibitor;

[0058] (5) 1.5% anti-wear agent;

[0059] (6) Conductive agent 2%;

[0060] (7) Filler 2%.

[0061] Mix 90 grams of lithium stearate soap with 364 g of PAO and perfluoropolyether mixture (the freezing point is -42 ° C, the viscosity at 100 ° C is 10mm 2 / s) Put it into the reactor and heat it up to 90°C, add 182g of PAO and perfluoropolyether mixture for dehydration; After cooling, the temperature was controlled at 180°C for 15 minutes, and the remaining 182g of PAO and perfluoropolyether mixture was added. After the temperature dropped to 80°C, 10g of 2,6-di-tert-butyl-p-cresol, 0.3g of mercaptobenzo Thiazole, 15 grams of iso-octyl diphenyl phosphite, 20 grams of iron oxide and 20 grams of melamine cyanurate salt, after grinding, degassing and other post-treatment proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com