Floating microalgae cultivation system and microalgae cultivation method

A microalgae culture, floating technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem that the film material is difficult to resist wave impact for a long time, insufficient low cost, large-scale microalgae production, Increase the cost and other issues to achieve the effect of increasing the yield of microalgae production, reducing installation costs and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

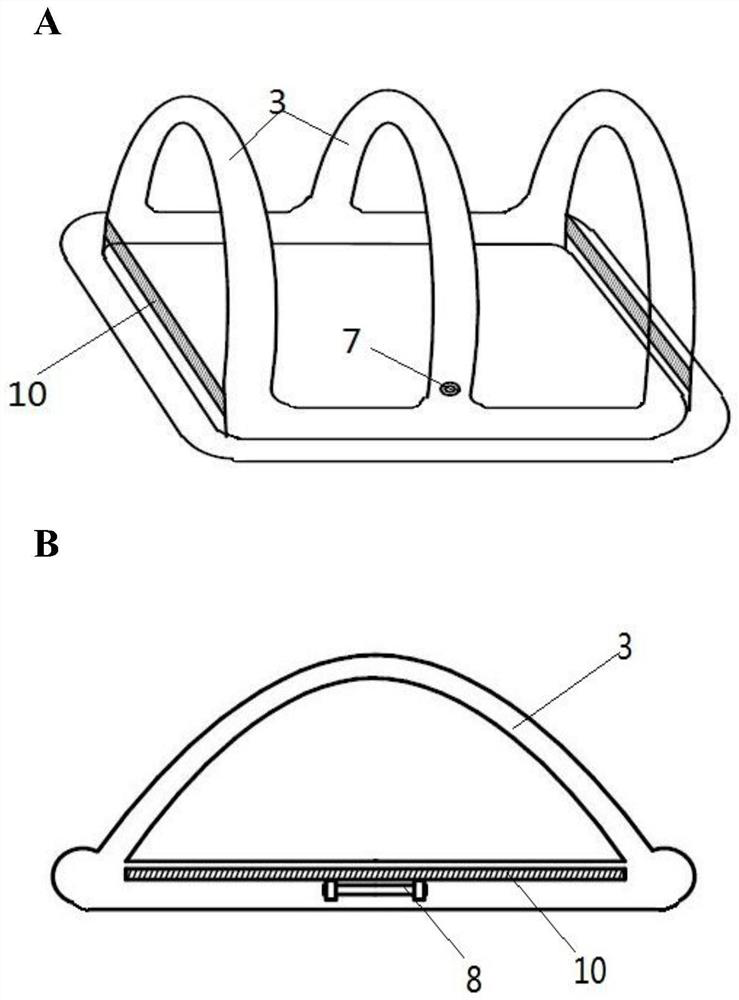

[0042] Example 1. Flexible floating carrier and thin-film photobioreactor with arched structure

[0043] Such as figure 1 , the floating carrier that makes in the present embodiment, its shape is open rectangle, and floating carrier is the rectangular parallelepiped pool that forms by welding together of transparent polyvinyl chloride (PVC) sealing pipe, and the diameter of inflatable pipe is 15.0cm. According to this method, the length of the floating carrier is 10.0m, the width is 2.0m, it has an arched structure, and the height is 1.5m. The floating carrier has a handle ring 8, which can be connected with ropes and anchors, and the floating carrier 1 is fixed in a certain area of water to prevent it from being washed away by water waves. The bottom surface of the floating carrier 1 is used to support the photobioreactor, maintain a rigid structure at the bottom of the reactor, and promote the sufficient mixing of the liquid inside the photobioreactor 2 . When in use, th...

Embodiment 2

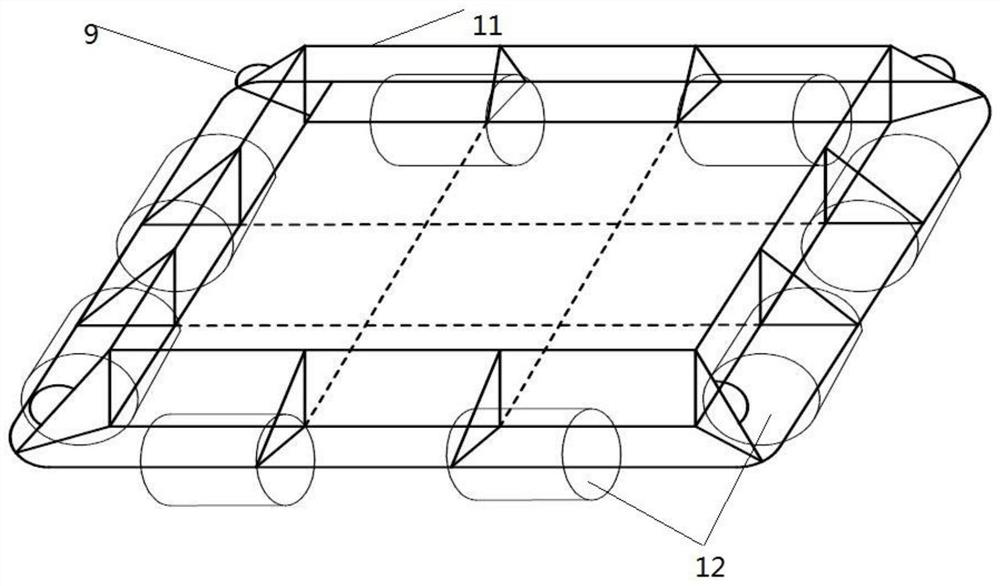

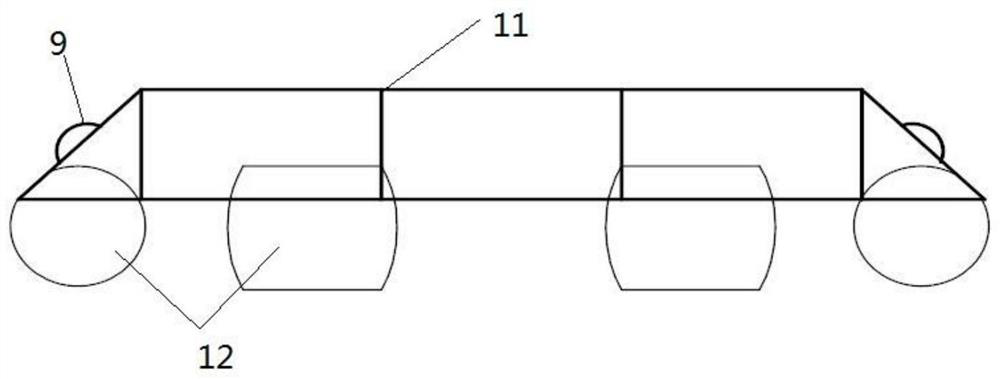

[0044] Example 2. Rigid floating carrier and thin-film photobioreactor with arched structure

[0045] The difference from Example 1 is that the floating carrier 1 of the rigid arch structure produced in this embodiment is rectangular or square, and its main material is stainless steel material with anti-seawater corrosion, and the arch structure 3 is an arch of stainless steel material. Tube, the diameter of the tube is 2.0cm. The production method is as follows: the carrier is four independent anti-seawater corrosion stainless steel support frames such as figure 2 and 3 , the frame is a triangle formed by connecting steel pipes through electric welding, and the diameter of the steel pipes used is 5.0cm. After docking and correction, the frame is connected into a cuboid through U-shaped cards. A certain number of foam plastic floats are fixed at the bottom of the frame to provide buoyancy. The arched steel pipe with a certain radian is connected to the top of the box by e...

Embodiment 3

[0047] Example 3. Rigid floating carrier has a thin-film photobioreactor with a cavity structure upper wall

[0048] Such as Figure 5 As shown, the upper surface of the reactor has a cavitation structure (ie, a transparent inflated gas). The top of the photobioreactor is provided with an inlet and outlet 6, which communicates with the inside of the cavity 4 through the upper surface. When in use, the reactor is placed in a floating carrier without an arched structure, and is fixed with the floating carrier through an adhesive tape buckle structure, such as Figure 6 shown. Then put materials for microalgae cultivation through the inlet and outlet 6, such as microalgae and microalgae culture fluid, and during the cultivation of microalgae, also take samples through the inlet and outlet to observe the growth of microalgae.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com