Method for regulating growth behavior of spinel phase in stainless steel slag

A technology of stainless steel slag and spinel phase, which is applied in the field of comprehensive utilization of metallurgical resources, can solve problems such as the difficulty of spinel phase growth, and achieve the effects of harmless treatment, increased crystallinity, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1: Take 1 kg of stainless steel slag from a steel plant as raw material, and its chemical composition is shown in Table 1. Put the stainless steel slag in a high-temperature furnace, raise the temperature to 1650°C, and add Al with a mass of 9% of the stainless steel slag 2 o 3 Modifier. Using a magnesia single-layer three-narrow-bladed propeller-type stirring paddle, stir at the center of the melt at a rate of 50rpm. During the stirring process, the paddle reciprocates longitudinally along the central axis of the melt, and heats it at 1650°C for 10 minutes;

[0042] Table 1 Chemical composition of stainless steel slag

[0043]

[0044] Step 2: Uniformly cool the slag from 1650°C to 1250°C at a cooling rate of 1°C / min. When the temperature drops to 1250°C and the melting modification treatment is completed, the shear force input is stopped and the slag is discharged;

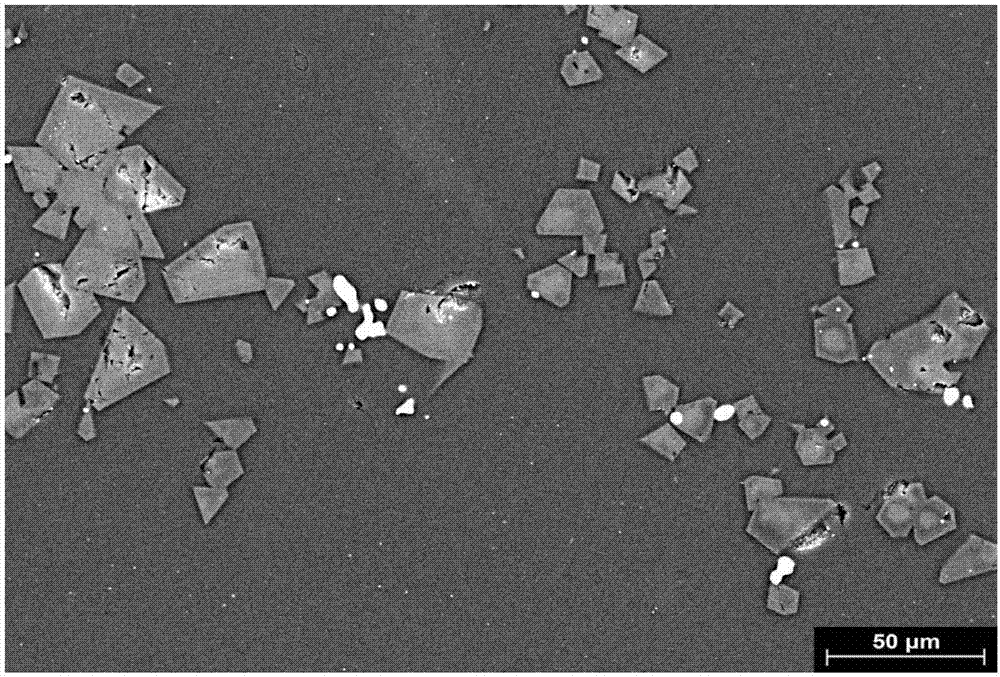

[0045] Step 3: The slag is cooled down to room temperature after water quenching to obtain...

Embodiment 2

[0049] Step 1: Take 1 kg of stainless steel slag from a steel factory as raw material, and its chemical composition is shown in Table 2. The stainless steel slag is placed in a high-temperature furnace, the temperature is raised to 1500° C., and an MnO modifier whose mass is 8% of the mass of the stainless steel slag is added. Use alumina double-layer three-narrow-bladed propeller-type stirring paddles, stir at a rate of 70rpm at a position lower than the center of the melt, and keep warm at 1500°C for 8 minutes;

[0050] Table 2 Chemical composition of stainless steel slag

[0051]

[0052] Step 2: Uniformly cool the slag from 1500°C to 1250°C at a cooling rate of 5°C / min. When the temperature drops to 1250°C and the melting modification treatment is completed, the shear force input is stopped and the slag is discharged;

[0053] Step 3: The slag is cooled down to room temperature after air quenching to obtain modified stainless steel slag.

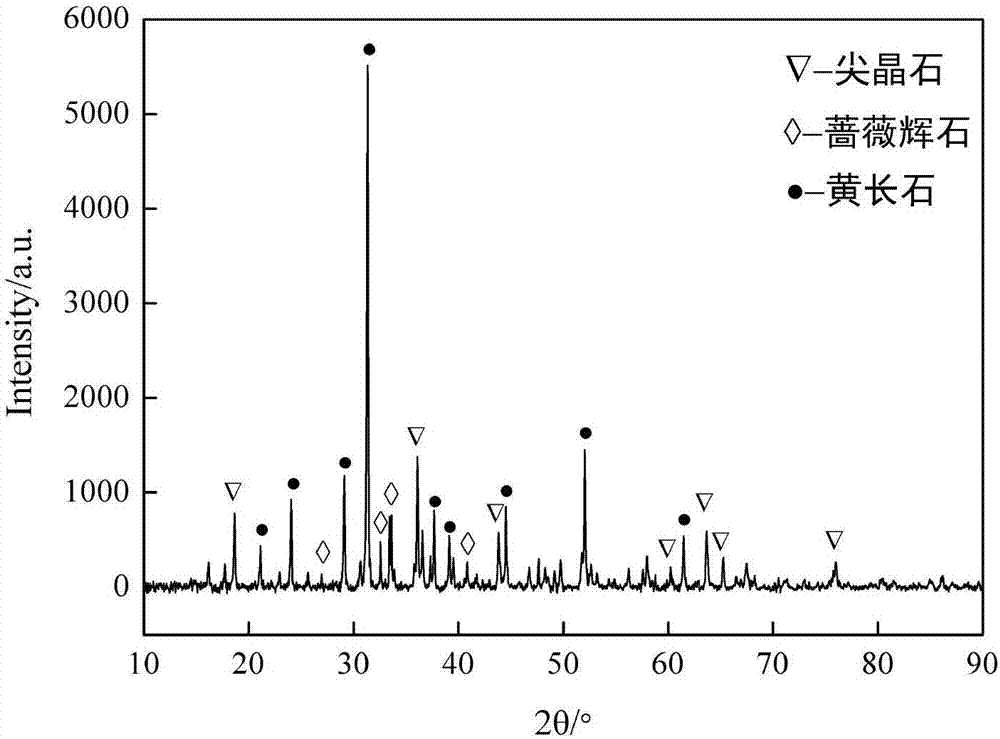

[0054] The results were ana...

Embodiment 3

[0057] Step 1: Take 800g of stainless steel slag from a steel factory as a raw material, and its chemical composition is shown in Table 3. Put the stainless steel slag in a high-temperature furnace, raise the temperature to 1630°C, and add FeC with a mass of 10% of the mass of the stainless steel slag 2 o 4 Modifier. Use molybdenum single-layer three-narrow-bladed propeller-type stirring paddle, stir at the upper position of the melt center at a rate of 30rpm, and keep warm at 1630°C for 1min;

[0058] Table 3 Chemical composition of stainless steel slag

[0059]

[0060] Step 2: Uniformly cool the slag from 1630°C to 1250°C at a cooling rate of 3°C / min. When the temperature drops to 1250°C and the melting modification treatment is completed, the shear force input is stopped and the slag is discharged;

[0061] Step 3: The slag is cooled down to room temperature after being treated with heat pouring, and the modified stainless steel slag is obtained.

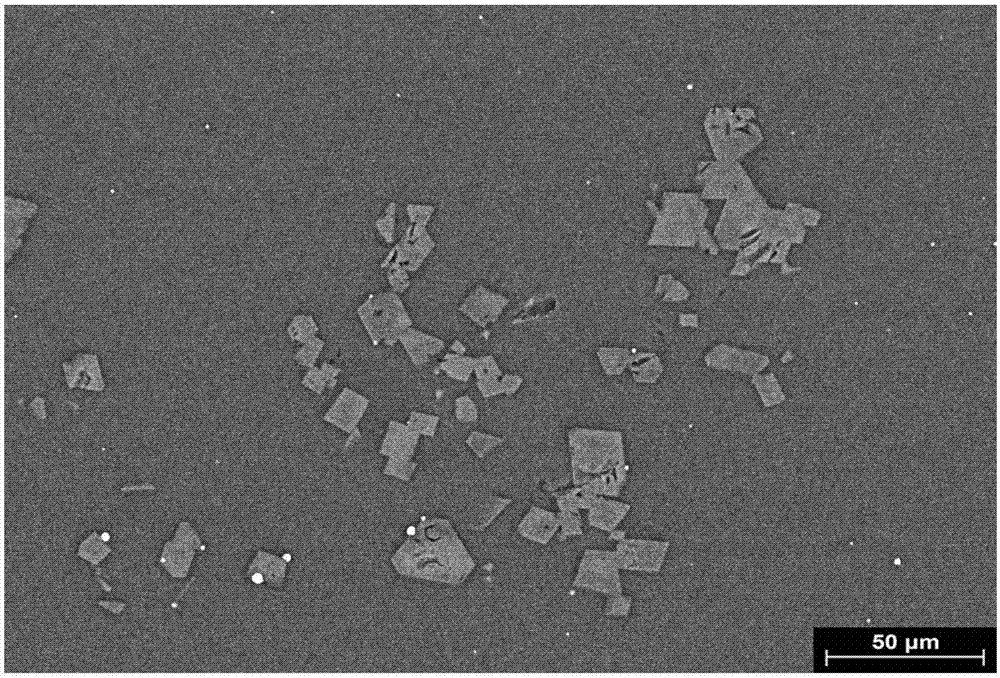

[0062] The resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com