High-tap-density metal oxide, preparation method and lithium-ion battery

A lithium-ion battery, tap density technology, applied in battery electrodes, circuits, electrode manufacturing, etc., can solve problems such as no solutions, achieve uniform composition, improve tap density, and improve the effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

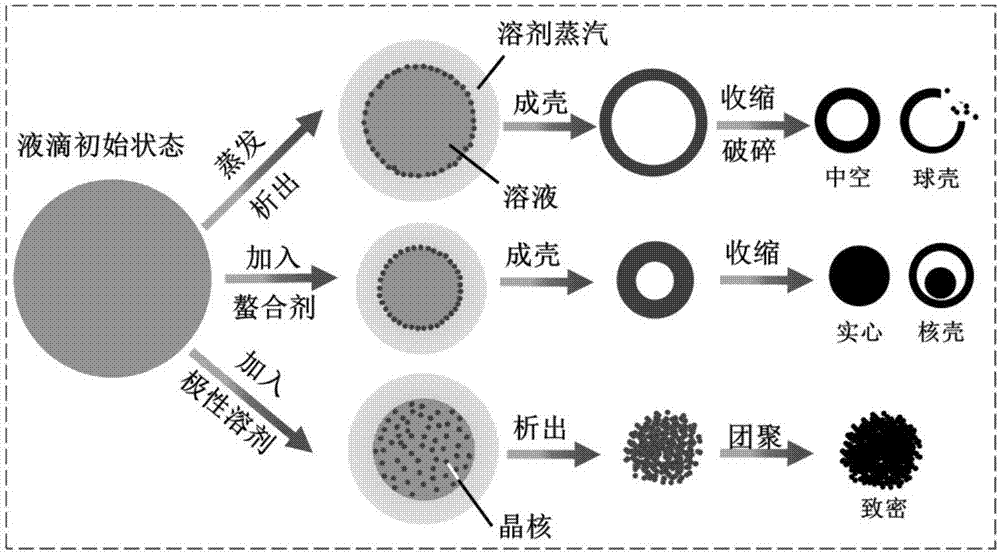

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of spray precursor solution

[0041] Dissolve nickel nitrate salt with deionized water to prepare a nickel nitrate solution with a metal ion concentration of 0.5mol / L, and then add an organic additive tartaric acid, wherein the tartaric acid concentrations are 0, 0.25mol / L, 0.5mol / L, and 1.0mol / L, and mixed uniformly to obtain spray precursor solutions with different additive concentrations.

[0042] (2) Preparation of high tap density metal oxides by spray pyrolysis

[0043] The different nickel nitrate spray precursor solutions described in (1) are atomized by an ultrasonic atomizer respectively, and the carrier gas (O2) with a flow rate of 5L / min is used to send the atomized spray precursor solution into the vertical The spray pyrolysis furnace is used for pyrolysis respectively. The spray pyrolysis temperature is 800°C. The pyrolysis products are collected by a powder collector to obtain solid and dense oxide powder.

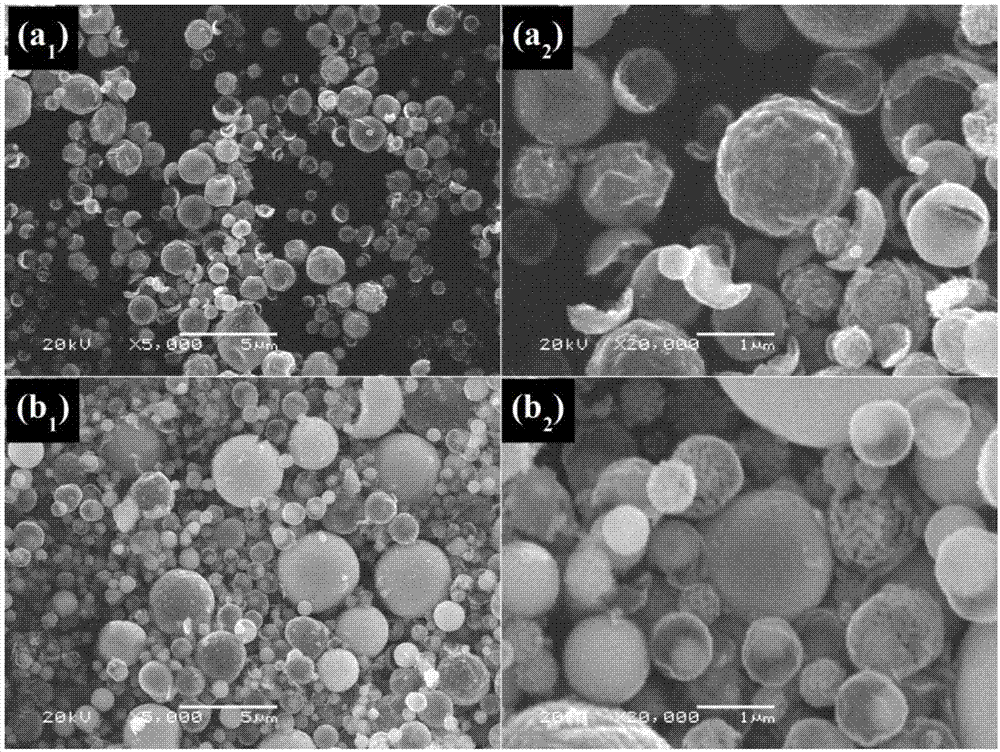

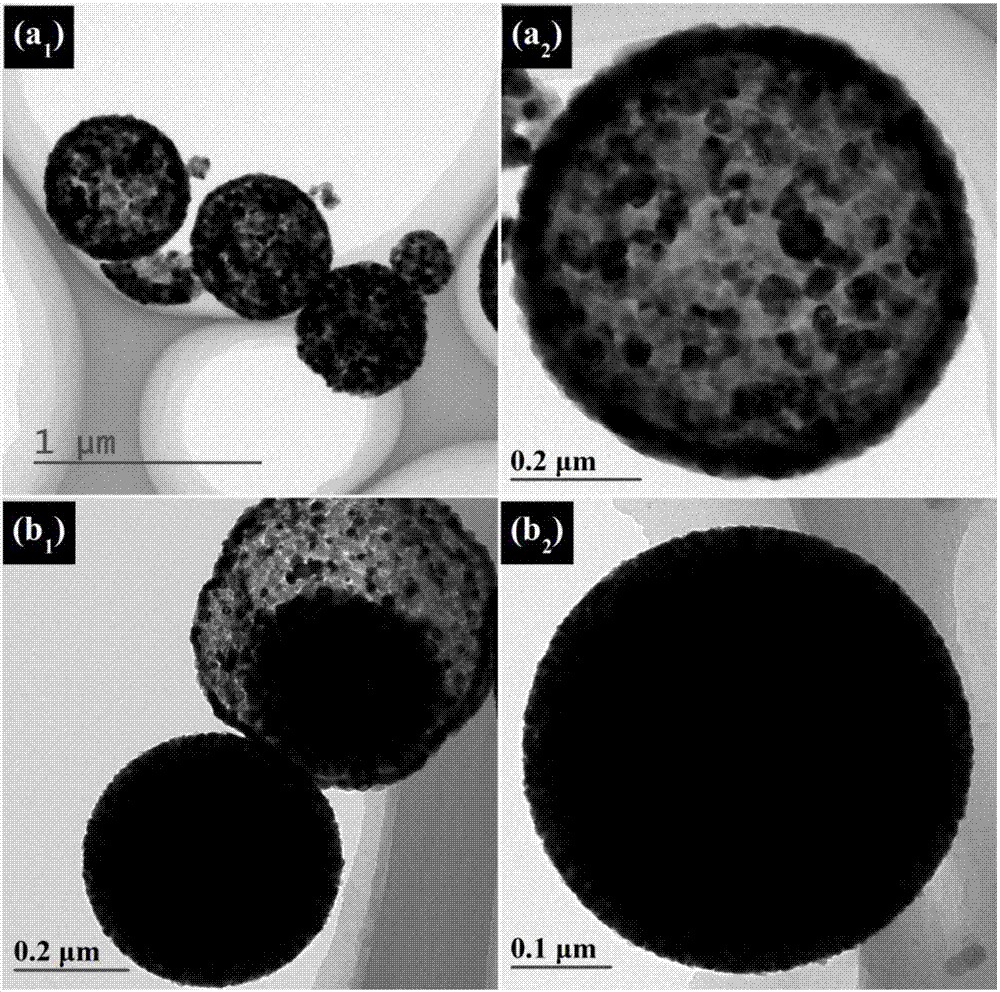

[0044] (3) Test analysis

...

Embodiment 2

[0050] (1) Preparation of spray precursor solution

[0051] Dissolve the cobalt acetate salt with deionized water to prepare a cobalt acetate solution with a cobalt ion concentration of 2mol / L, then add the organic additive dimethyl sulfoxide (DMSO), wherein the dimethyl sulfoxide concentration is 1mol / L, mix After being uniform, a spray precursor solution is obtained.

[0052] (2) Preparation of high tap density metal oxides by spray pyrolysis

[0053] The nickel nitrate spray precursor solution described in (1) is utilized ultrasonic nebulizer atomization, utilizes the carrier gas (O 2 ) Send the atomized spray precursor solution into a vertical spray pyrolysis furnace for pyrolysis respectively. The pyrolysis product can obtain solid and dense oxide powder.

[0054] (3) Test analysis

[0055] Carry out X-ray diffraction (XRD), scanning electron microscope (SEM), transmission electron microscope (TEM), tap density (TD) test analysis to the material collected in (2) respe...

Embodiment 3

[0060] (1) Preparation of spray precursor solution

[0061] Dissolve the mixed salts of nickel chloride, cobalt chloride and aluminum chloride with de-distilled water to prepare a mixed nickel chloride, cobalt chloride and aluminum chloride with a total metal ion concentration of 0.5mol / L of nickel ions, cobalt ions and aluminum ions solution, wherein the ratio of the amount of each metal element is Ni:Co:Al=80:15:5, and then add the organic additive N,N-dimethylformamide (DMF), wherein N,N-dimethylformamide The amide concentration is 0.75mol / L, and after mixing evenly, a spray precursor solution is obtained.

[0062] (2) Preparation of high tap density metal oxides by spray pyrolysis

[0063] The spray precursor mixed solution described in (1) is atomized by an ultrasonic atomizer, and the carrier gas (O 2 ) Send the atomized spray precursor solution into a vertical spray pyrolysis furnace for pyrolysis respectively, the spray pyrolysis temperature is 800°C, and the pyrolys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com