Modified nanofiltration membrane suitable for recycling industrial wastewater, and production method and application thereof

A technology of industrial wastewater and nanofiltration membranes, which is applied in chemical instruments and methods, membranes, membrane technologies, etc., can solve the problems that restrict the promotion and application of nanofiltration membrane technology, have little effect, and low water flux, and achieve good industrial application The effect of prospect, simple preparation process and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Pour 60~80 g of dry PES into a three-necked flask, add 460~500 ml of deionized water, pass high-pressure nitrogen for 15~25 minutes, and add 0.4%~0.6% of BPO. After excitation for 25-30 min, 300-320ml of PEGMA solution was added dropwise, and reacted in a constant temperature water bath at 65-75°C for 1.8-2.2 h. After the reaction was completed, cool to room temperature, immerse the product in absolute ethanol for 20-24 hours, then wash thoroughly, collect the product, and dry it to constant weight at 70-90°C to obtain PES-g-PEGMA.

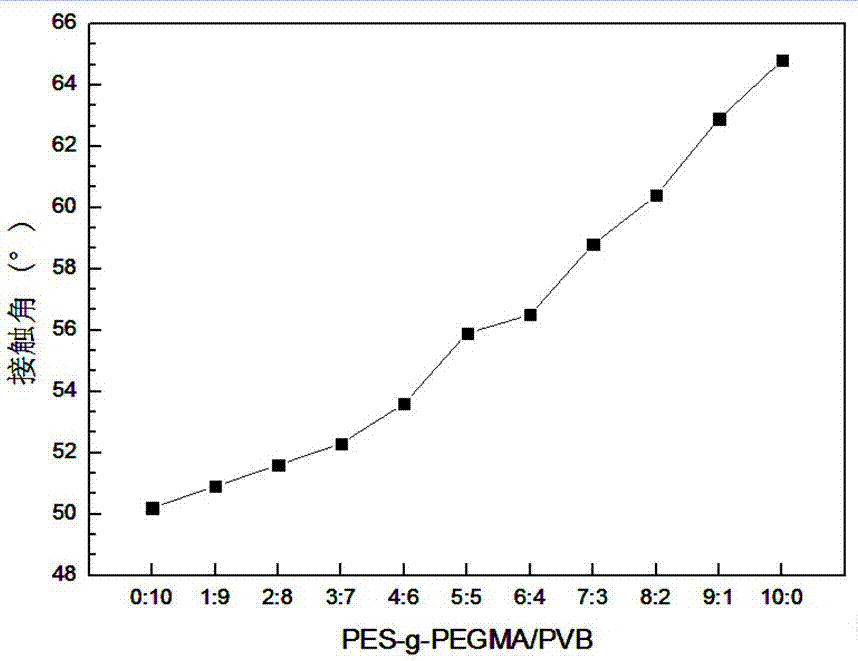

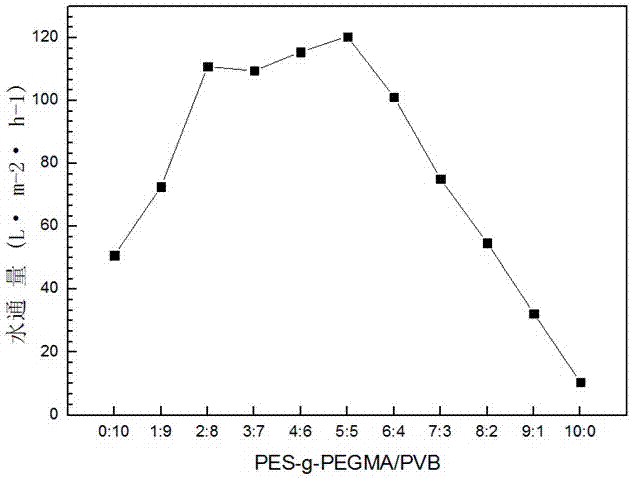

[0026] 2. Dissolve PES-g-PEGMA and PVB with a total mass ratio of 12~16% in N,N-dimethylformamide, stir in a constant temperature water bath at 75~85°C for 7~8 hours, and then reach a uniform and stable casting Membrane fluid. Degas the casting solution at a constant temperature of 40~50°C and vacuum conditions.

[0027] 3. Pour the obtained mixed casting solution on a clean glass plate, and use a scraper machine to form a flat film wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com