Method for improving hydrogen evolution/hydrogen reabsorption performance of lithium borohydride

A technology of lithium borohydride and performance, applied in chemical instruments and methods, borane/diborane hydride, hydrogen and other directions, can solve the problems of potential safety hazards, low production process yield, etc., and achieves low price and simple process. , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

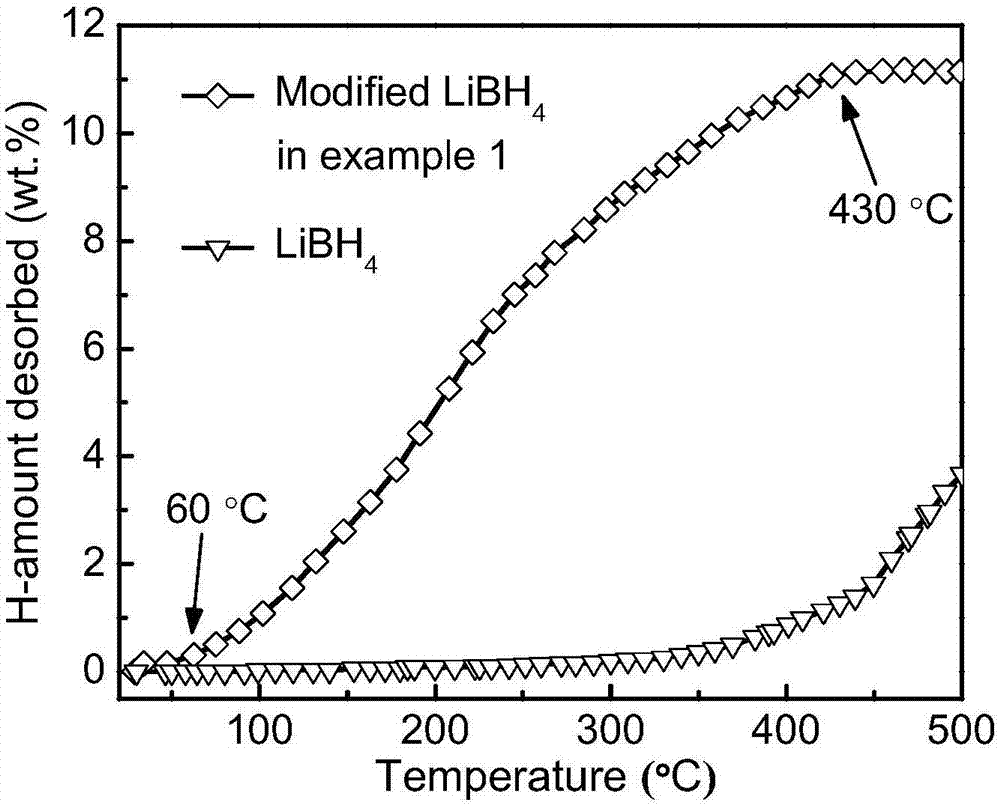

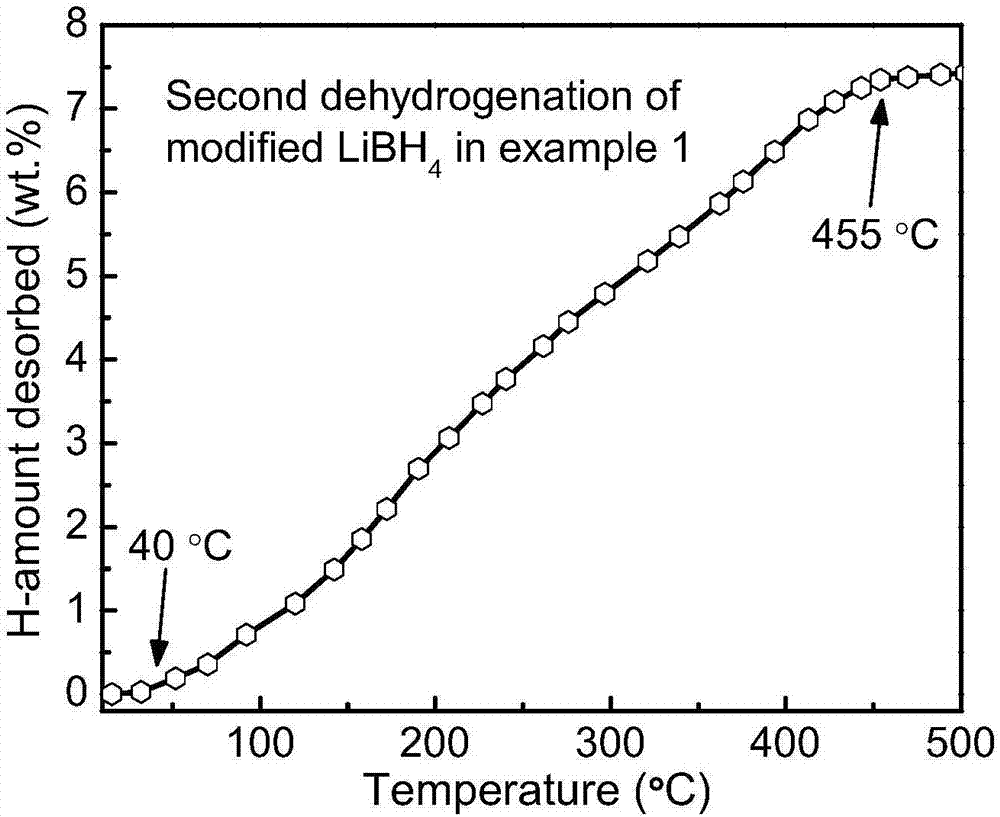

[0025] According to the molar ratio of 1:3, the metal nickel and aluminum flakes with a purity of not less than 99.5% are weighed; the nickel flakes and aluminum flakes are smelted into alloys using a high-frequency magnetic levitation induction melting furnace; the smelted block alloys are mechanically crushed into particle sizes Alloy powder less than 300 mesh; measure a certain amount of 5mol / L sodium hydroxide solution in a beaker, and place the beaker in a water bath at 80°C, add the alloy powder into the sodium hydroxide solution and stir, after 1h Washing with deionized water and absolute ethanol in sequence, followed by vacuum drying to obtain the alkali-treated product; weighing lithium borohydride and alkali-treated product according to the mass ratio of 1:5, pouring them into anhydrous tetrahydrofuran solution and stirring, and then The solution was extracted under vacuum to obtain modified lithium borohydride. Depend on figure 1 It can be seen that the modified li...

Embodiment 2

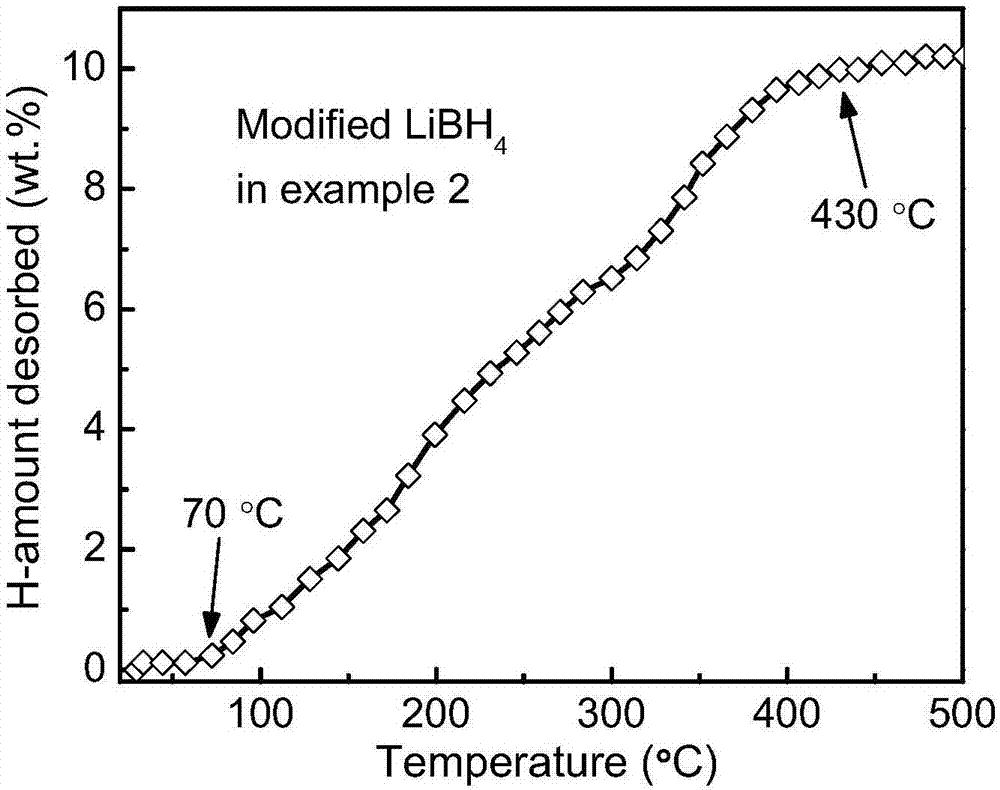

[0027] According to the molar ratio of 1:3, the metal nickel and aluminum flakes with a purity of not less than 99.5% are weighed; the nickel flakes and aluminum flakes are smelted into alloys using a high-frequency magnetic levitation induction melting furnace; the smelted block alloys are mechanically crushed into particle sizes Alloy powder less than 300 mesh; measure a certain amount of 5mol / L sodium hydroxide solution in a beaker, and place the beaker in a water bath at 75°C, add the alloy powder into the sodium hydroxide solution and stir, after 1h Wash with deionized water and absolute ethanol in sequence, and then vacuum dry to obtain the alkali-treated product; weigh lithium borohydride and alkali-treated product according to the mass ratio of 2:5, pour into anhydrous tetrahydrofuran solution and stir, and then The solution was extracted under vacuum to obtain modified lithium borohydride. Depend on image 3 It can be seen that the modified lithium borohydride starts...

Embodiment 3

[0029] According to the molar ratio of 1:3, the metal nickel and aluminum flakes with a purity of not less than 99.5% are weighed; the nickel flakes and aluminum flakes are smelted into alloys using a high-frequency magnetic levitation induction melting furnace; the smelted block alloys are mechanically crushed into particle sizes Alloy powder less than 300 mesh; measure a certain amount of 5mol / L sodium hydroxide solution in a beaker, and place the beaker in a water bath at 85°C, add the alloy powder into the sodium hydroxide solution and stir, after 1h Wash with deionized water and absolute ethanol in sequence, and then vacuum dry to obtain the alkali-treated product; weigh lithium borohydride and alkali-treated product according to the mass ratio of 3:5, pour into anhydrous tetrahydrofuran solution and stir, and then The solution was extracted under vacuum to obtain modified lithium borohydride. Depend on Figure 4 It can be seen that the modified lithium borohydride start...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com