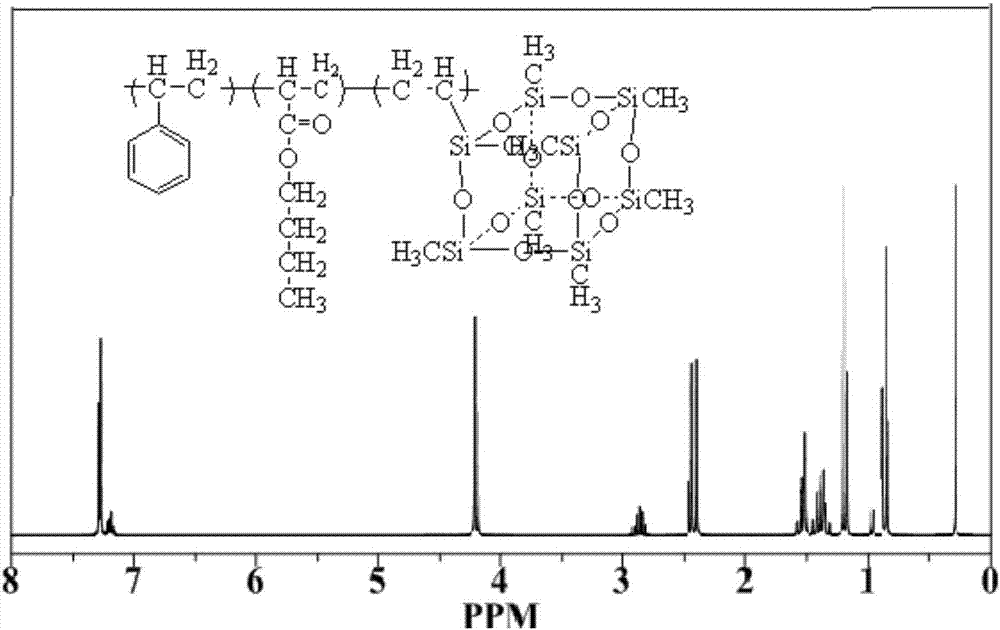

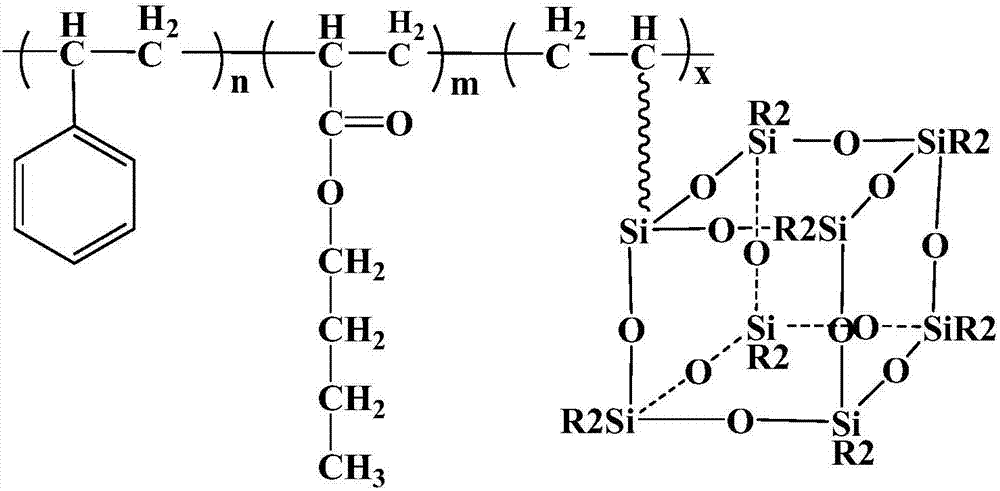

POSS modified styrene-acrylic emulsion copolymer, preparation method and application

A technology of styrene-acrylic emulsion and copolymer, applied in the direction of coating, etc., can solve the problems of pollution, not suitable for large-scale production, and the existence of solvent environment, etc., and achieve the effect of simple polymerization method, high production efficiency and strong self-cleaning property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Prepare a blank sample:

[0029] (1) Mix 25 parts of water, 10 parts of styrene, 10 parts of butyl acrylate, and 1.5-3 parts of emulsifier evenly at low speed (60-80 rpm), heat up to 75°C, and stir for 30 minutes ;

[0030] (2) Mix 1-2 parts of water-soluble initiator with ten times of water;

[0031] (3) Mix 25 parts of water, 10 parts of styrene, 10 parts of butyl acrylate, and 1.5 to 3 parts of emulsifier (OP-10);

[0032] (4) Add the mixture of step (2) and step (3) dropwise to the product of step (1) at the same time, control the dropwise addition in 2.5 hours, and keep the reaction temperature at 85°C;

[0033] (5) After the dropwise addition, the reaction was continued at 80°C for 1 hour, and when the temperature was lowered to 45°C, a pH value regulator was added to adjust the pH value to 7-8, and the material was discharged after cooling down.

[0034] (6) Take 30 parts of the above-prepared emulsion, add 0.5 part of film-forming aid, 3 g of pigment (such as...

Embodiment 2

[0036] (1) Under the condition of low speed, mix 25 parts of water, 10 parts of styrene, 10 parts of butyl acrylate, and 1.5-3 parts of emulsifier evenly, heat up to 75°C, and stir for 30 minutes;

[0037] (2) Mix 1-2 parts of water-soluble initiator with ten times of water;

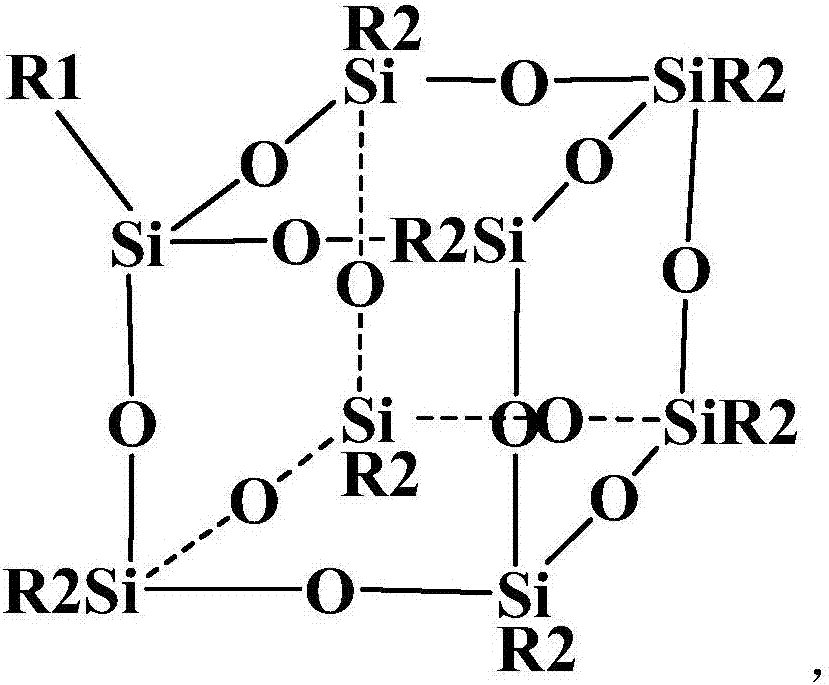

[0038] (3) Prepare 1 part of POSS (one vinyl heptamethyl POSS);

[0039] (4) Mix 25 parts of water, 10 parts of styrene, 10 parts of butyl acrylate, and 1.5 to 3 parts of emulsifier (OP-10);

[0040] (5) Add the mixture of step (2) and step (4) dropwise to step (1), control the dropwise addition in 2.5 hours, and keep the reaction temperature at 85°C;

[0041] (6) Add half of the POSS in step (3) after 1 hour of reaction for 10 to 30 minutes, and add the remaining half after 2 hours of reaction for 10 to 30 minutes;

[0042] (7) After the dropwise addition, continue to react at 80°C for 1 hour, add a pH value regulator when the temperature is lowered to 45°C, adjust the pH value to 7-8, cool down and d...

Embodiment 3

[0045] (1) Under the condition of low speed, mix 25 parts of water, 10 parts of styrene, 10 parts of butyl acrylate, and 1.5-3 parts of emulsifier evenly, heat up to 75°C, and stir for 30 minutes;

[0046] (2) Mix 1-2 parts of water-soluble initiator with ten times of water;

[0047] (3) 3 parts of POSS (one vinyl heptamethyl POSS);

[0048] (4) Mix 25 parts of water, 10 parts of styrene, 10 parts of butyl acrylate, and 1.5 to 3 parts of emulsifier (OP-10);

[0049] (5) Add the mixture of step (2) and step (4) dropwise to step (1) at the same time, control the dropwise addition in 2.5 hours, and keep the reaction temperature at 85°C;

[0050] (6) Add half of the POSS in step (3) after 1 hour of reaction for 10 to 30 minutes, and add the remaining half after 2 hours of reaction for 10 to 30 minutes;

[0051] (7) After the dropwise addition, continue to react at 80°C for 1 hour, add a pH value regulator when the temperature is lowered to 45°C, adjust the pH value to 7-8, cool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com