Low-viscosity, low-smoke and flame-retardant high-speed elevator balance compensating chain PVC sheath material and preparation method thereof

A low-smoke flame-retardant, balanced compensation technology, applied in the field of polymer composite material preparation, can solve the problems of fast coating speed, uneven elastic recovery, slow second coating speed, etc., and achieves easy extrusion molding processing. , Small change rate of tensile strength, good effect of smoke suppression and flame retardant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

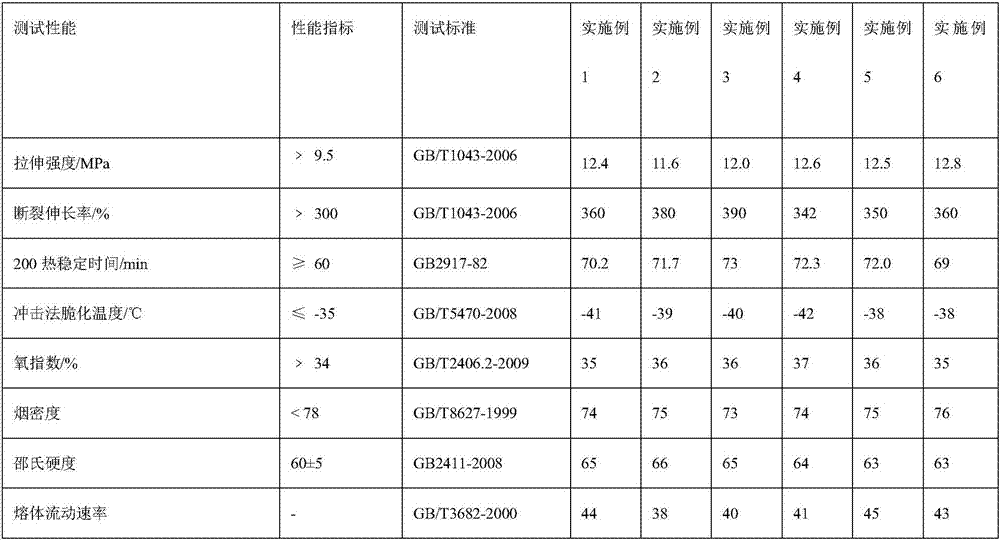

Examples

Embodiment 1

[0011] The special low-viscosity, low-smoke, flame-retardant PVC elastomer material for elevator balance compensation chain sheath of this embodiment is a blend system composed of PVC resin and other additives. Additives include plasticizers, stabilizers, lubricants, flame retardants, smoke suppressants, viscosity reducers and pigments. PVC is made by mixing two resins with a degree of polymerization of 800 and 2500 according to 1:1.5; there are two plasticizers, the first is dioctyl phthalate, the second is diphenyl monooctyl phosphate, o Dioctyl phthalate and diphenyl monooctyl phosphate are mixed in a weight ratio of 5-10:1 to form a mixed plasticizer. In the 238kg special PVC elastomer material for elevator balance compensation chain sheath, the components and contents are as follows: PVC resin 100kg, heat stabilizer non-toxic liquid calcium-zinc stabilizer 7kg, plasticizer dioctyl phthalate 70kg, diphenyl iso-octyl phosphate 10kg, lubricant zinc stearate 3.5kg, flame reta...

Embodiment 2

[0017] The rest of this embodiment is the same as embodiment 1, the difference is: in the 269kg of special PVC elastomer material for elevator balance compensation chain sheath, each component and corresponding content are as follows: PVC resin 100kg, no heat stabilizer Toxic liquid calcium-zinc stabilizer 7kg, plasticizer dioctyl phthalate 75kg, diphenyl iso-octyl phosphate 10kg, lubricant zinc stearate 3.5kg, pigment carbon black 0.3kg, flame retardant modification Micron hydrotalcite 50kg, smoke suppressant zinc borate 8.2kg, 15kg chlorinated paraffin (chlorine content 20-40%). Among them, PVC is a 1:1 mixture of two resins with a degree of polymerization of 800 and 2500.

[0018] In step ②, the weight of the various raw materials weighed corresponds to the content of the above-mentioned components, 100 kg of PVC mixed resin, 7 kg of heat stabilizer non-toxic liquid calcium-zinc stabilizer, and 75 kg of plasticizer dioctyl phthalate , Diphenyl iso-octyl phosphate 10kg, chlori...

Embodiment 3

[0020] The rest of this embodiment is the same as embodiment 1, the difference is: in the 274kg of special PVC elastomer material for elevator balance compensation chain sheath, the components and corresponding contents are as follows:: PVC resin 100kg, heat stabilizer Non-toxic liquid calcium-zinc stabilizer 7kg, plasticizer dioctyl phthalate 75kg, diphenyl iso-octyl phosphate 10kg, lubricant zinc stearate 3.5kg, pigment carbon black 0.3kg, flame retardant modification 50kg of natural micron hydrotalcite, 8.2kg of smoke suppressant zinc borate, 20kg of chlorinated paraffin (chlorine content 20-40%). Among them, PVC is made by mixing two resins with a degree of polymerization of 800 and 2500 according to 1:2.

[0021] In step ②, the weight of the various raw materials weighed corresponds to the content of the above-mentioned components, 100 kg of PVC mixed resin, 7 kg of heat stabilizer non-toxic liquid calcium-zinc stabilizer, and 75 kg of plasticizer dioctyl phthalate , Diphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com