A kind of processing method of whole fruit functional drink of lychee with shell

A processing method and functional technology, which is applied in the field of processing functional beverages with shelled lychee whole fruit, can solve the problems of loss of active ingredients, poor health care effect, backward processing technology, etc., and achieve short production cycle, easy control, and long-lasting fragrance. long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

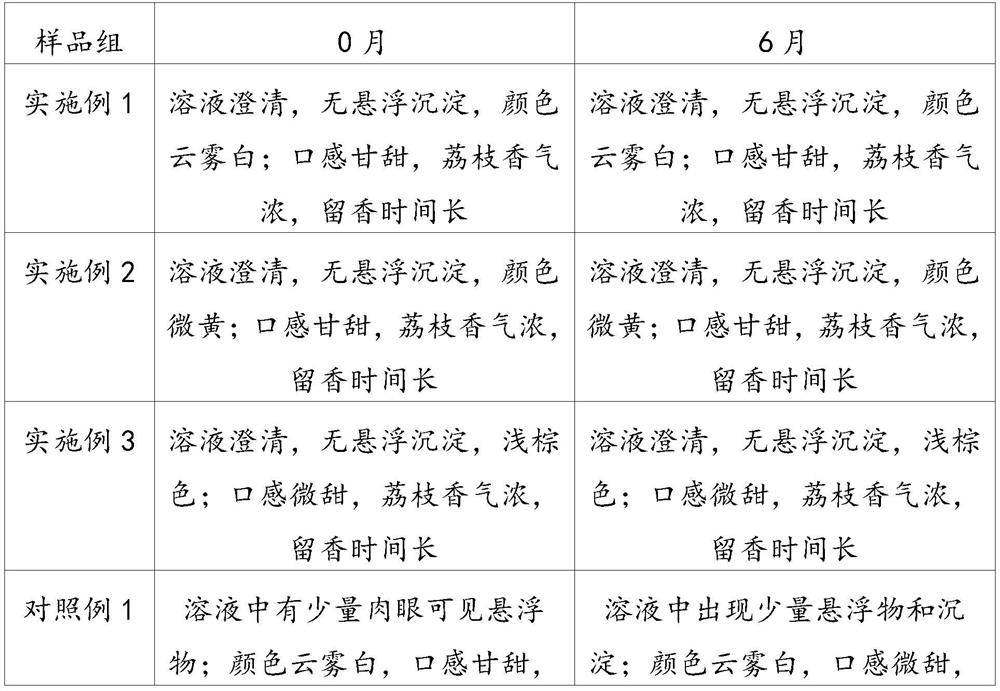

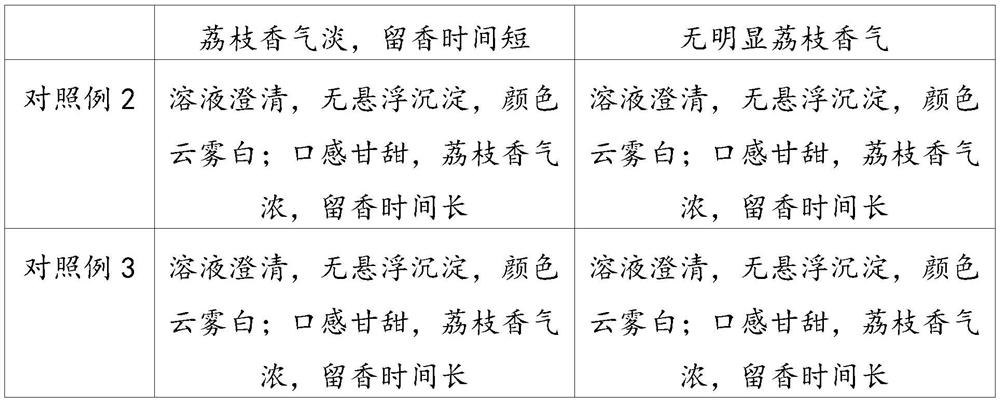

Examples

Embodiment 1

[0028] 1) After the fresh lychee is washed, divided, pitted and peeled mechanically crushed, add 4 times the volume of water, 0.01 times cellulase and pectinase (cellulase: pectin) according to the weight of the fruit after mechanical crushing. The ratio of enzyme is 1:1); Ultrasound-assisted low-speed squeezing and juicing for 80 minutes, ultrasonic power 300W, screw speed 80r / min; vacuum filtration to obtain the whole fruit liquid of litchi;

[0029] 2) Filter the obtained stock solution through a 0.45 μm microfiltration membrane at a transmembrane pressure of 0.2 MPa, and then filter through an ultrafiltration membrane with a molecular weight cut-off of 100 kDa at 0.3 MPa, then the permeate is evaporated and concentrated by thin film, and then added with water Set the volume to about 2 times the fruit volume (m:V=1:2), and then take it as 100%, add 0.2% inulin, 1% fructose syrup, 2% citric acid and 0.1% vitamin C in mass percentage;

[0030] 3) The obtained lychee beverage ...

Embodiment 2

[0032] 1) After the fresh lychee is washed, divided, pitted, and peeled mechanically mashed, add 2 times the volume of water, 0.008 times of cellulase and pectinase (cellulase: pectin) according to the weight of the fruit after mechanical mashing. The ratio of enzyme is 2:1); Ultrasound-assisted low-speed squeezing and juicing for 90 minutes, ultrasonic power 200W, screw speed 60r / min; vacuum filtration to obtain the whole fruit liquid of litchi;

[0033] 4) 2) Filter the obtained stock solution through a 0.45 μm microfiltration membrane at a transmembrane pressure of 0.2 MPa, then filter through an ultrafiltration membrane with a molecular weight cut-off of 50 kDa at 0.4 MPa, and then concentrate the permeate by thin film evaporation , add water to make up to about 2 times the fruit volume (m:V=1:2), and then take it as 100%, add 0.2% inulin, 1% fructose syrup, 2% citric acid and 0.1% vitamin C in mass percentage ;

[0034] 3) The obtained lychee beverage is placed in the tr...

Embodiment 3

[0036] 1) After the fresh lychee is washed, divided, pitted, and peeled mechanically mashed, add 1 times the volume of water, 0.005 times of cellulase and pectinase (cellulase: pectin) according to the weight of the fruit after mechanical mashing. The ratio of enzyme is 1:2); Ultrasound-assisted low-speed squeezing and juicing for 60 minutes, ultrasonic power 400W, screw speed 90r / min; vacuum filtration to obtain the whole fruit liquid of litchi;

[0037] 5) 2) Filter the obtained stock solution through a 0.22 μm microfiltration membrane at a transmembrane pressure of 0.4 MPa, then filter through an ultrafiltration membrane with a molecular weight cut-off of 20 kDa at 0.5 MPa, and then concentrate the permeate by thin film evaporation , add water to make up to about 2 times the fruit volume (m:V=1:2), and then take it as 100%, add 0.2% inulin, 1% fructose syrup, 2% citric acid and 0.1% vitamin C in mass percentage ;

[0038] 3) The obtained lychee beverage is placed in a trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com