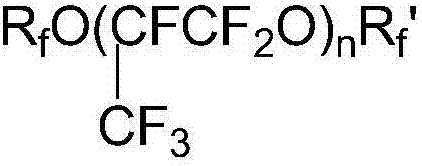

Perfluoropolyether and preparation method thereof

A perfluoropolyether and perfluoropolyether peroxide technology, which is applied in the field of perfluoropolyether preparation, can solve the problems of large losses of olefins, threats to safety processes, and complicated processes, and achieve huge economic benefits and Social benefits, low risk of explosion, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

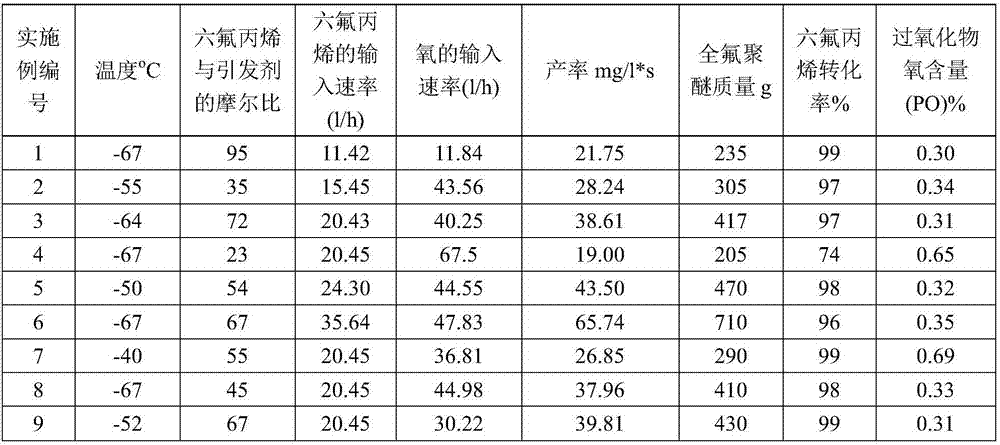

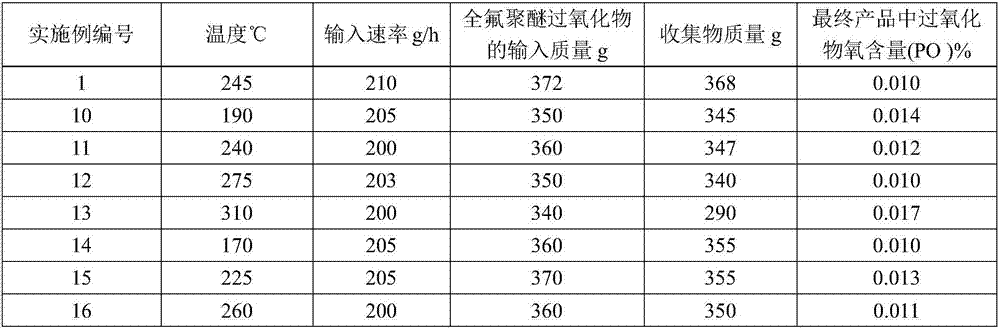

[0049] (1) Synthesis of perfluoropolyether peroxide:

[0050] 570g of liquid hexafluoropropylene is concentrated in a 1.0L reactor equipped with a mixer / stirrer. The mixture of oxygen and initiator is continuously fed into the reactor, and the reaction temperature is -67°C. The delivery rate of hexafluoropropylene is 11.42L / h, the rate of initiator fluorine is 0.12L / h, and the rate of oxygen is 11.84L / h. The temperature of the reactor is maintained at -67°C, and the reaction material containing the target product flows out of the reactor into the hot receiver. When the temperature of the receiver is 20-70°C, the reaction material is separated into hexafluoropropylene and acyl fluoride. The polyether of the group, the separated hexafluoropropylene is recovered and sent to the reactor again (and the obtained polyether product of the acyl fluoride group is directly put into the collector), reacted for 3 hours, and obtained containing active oxygen (PO) of 0.31 % Of 372g product.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com