Modified glass fiber reinforced PA6 composition and preparation method thereof

A composition and modification technology, applied in the field of modified glass fiber reinforced PA6 composition and its preparation, can solve the problems of affecting the performance of compression-resistant parts, affecting the appearance of PA parts, etc., to improve mechanical strength, increase Absorption and dissipation effect, effect of reducing glass fiber exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

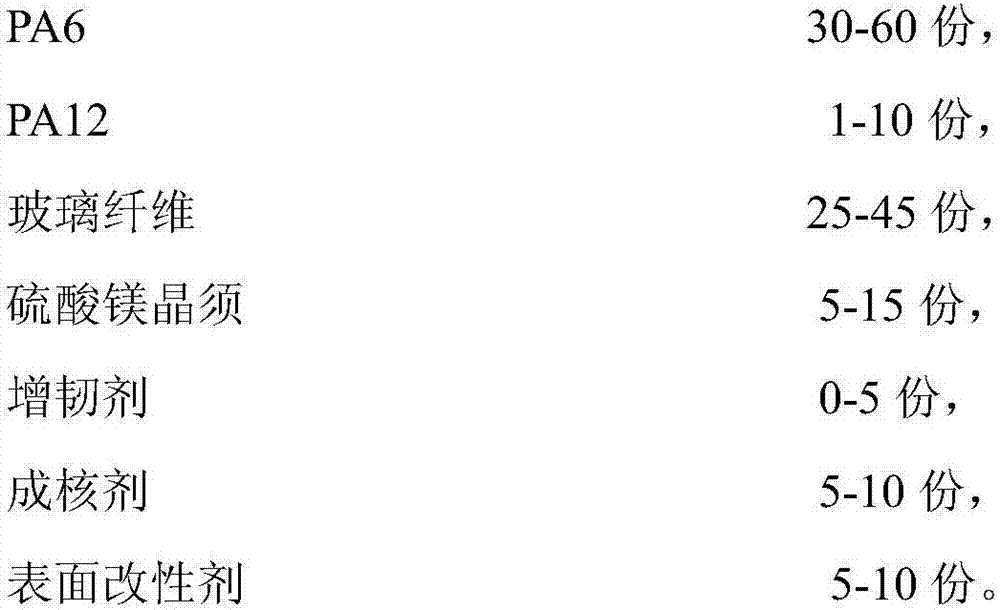

Method used

Image

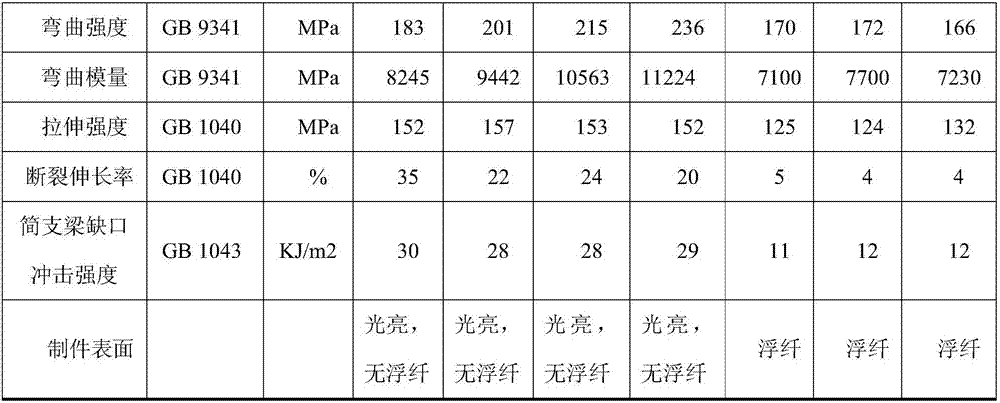

Examples

Embodiment 1

[0035] (1) Dry PA6 at 110°C for 4 hours; PA12 at 110°C for 4 hours;

[0036] (2) Weigh dry 60 parts of PA6, 1 part of PA12, 25 parts of glass fiber, 5 parts of magnesium sulfate whiskers, 5 parts of sodium benzoate, 5 parts of surface modifier (2 parts of modified B a mixture of bis fatty acid amide and 3 parts silicone);

[0037] (3) Stir the material weighed in the above step (2) in a high-speed mixer for 3 minutes;

[0038] (4) Then the above-mentioned uniformly mixed material is added to the feeding port of the twin-screw extruder;

[0039] (5) The material is melted and extruded by a twin-screw extruder, and granulated;

[0040] The processing technology of the twin-screw extruder is as follows: the temperature of the first zone of the twin-screw extruder is 230°C, the temperature of the second zone is 245°C, the temperature of the third zone is 255°C, the temperature of the fourth zone is 265°C, the temperature of the fifth zone is 260°C, and the temperature of the six...

Embodiment 2

[0042] (1) Dry PA6 at 140°C for 5 hours; PA12 at 120°C for 5 hours;

[0043] (2) take by weighing dry 40 parts of PA6, 10 parts of PA12, 30 parts of glass fiber, 5 parts of magnesium sulfate whiskers, 5 parts of toughening agent maleic anhydride grafted ethylene-octene copolymer, 10 parts The sodium benzoate of part, the surface modifier of 8 parts (the mixture of 3 parts of modified ethylene bis fatty acid amides and 5 parts of silicone);

[0044] (3) Stir the material weighed in the above step (2) in a high-speed mixer for 5 minutes;

[0045] (4) Then the above-mentioned uniformly mixed material is added to the feeding port of the twin-screw extruder;

[0046] (5) The material is melted and extruded by a twin-screw extruder, and granulated;

[0047] The processing technology of the twin-screw extruder is as follows: the temperature of the first zone of the twin-screw extruder is 220°C, the temperature of the second zone is 225°C, the temperature of the third zone is 235°C,...

Embodiment 3

[0049] (1) Dry PA6 at 120°C for 5 hours; PA12 at 120°C for 5 hours;

[0050] (2) Weigh dry 40 parts of PA6, 5 parts of PA12, 35 parts of glass fiber, 10 parts of magnesium sulfate whiskers, 3 parts of toughening agent ethylene-methyl acrylate copolymer, 2 parts of ethylene-acrylic acid Methyl ester-glycidyl methacrylate, 8 parts of sodium benzoate, 10 parts of surface modifier (a mixture of 5 parts of modified ethylene bis fatty acid amide and 5 parts of silicone);

[0051] (3) Stir the material weighed in the above step (2) in a high-speed mixer for 5 minutes;

[0052] (4) Then the above-mentioned uniformly mixed material is added to the feeding port of the twin-screw extruder;

[0053] (5) The material is melted and extruded by a twin-screw extruder, and granulated;

[0054] The processing technology of the twin-screw extruder is as follows: the temperature of the first zone of the twin-screw extruder is 240°C, the temperature of the second zone is 255°C, the temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com