Seawater well cementing slow release type fluid loss additive and preparation method and application thereof

A water loss reducer, slow-release technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the difficulty in meeting the requirements of cement slurry dispersion, difficult to control slurry fluidity, seawater performance inspection less problems, to alleviate the excessively retarded setting phenomenon, avoid compatibility problems, and improve the effect of fluid loss control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

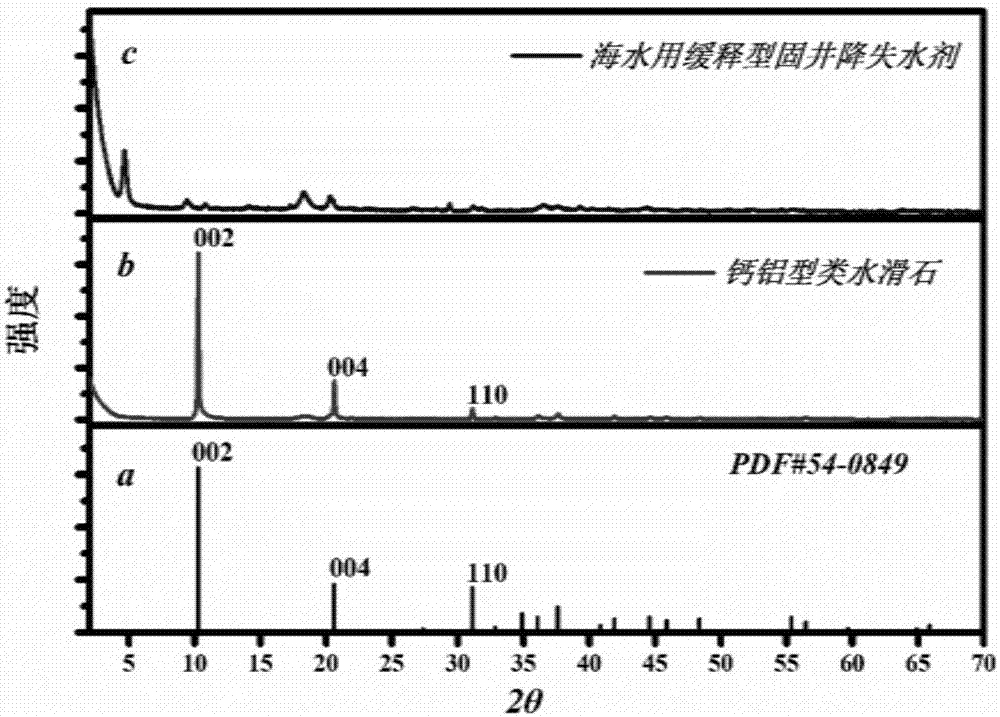

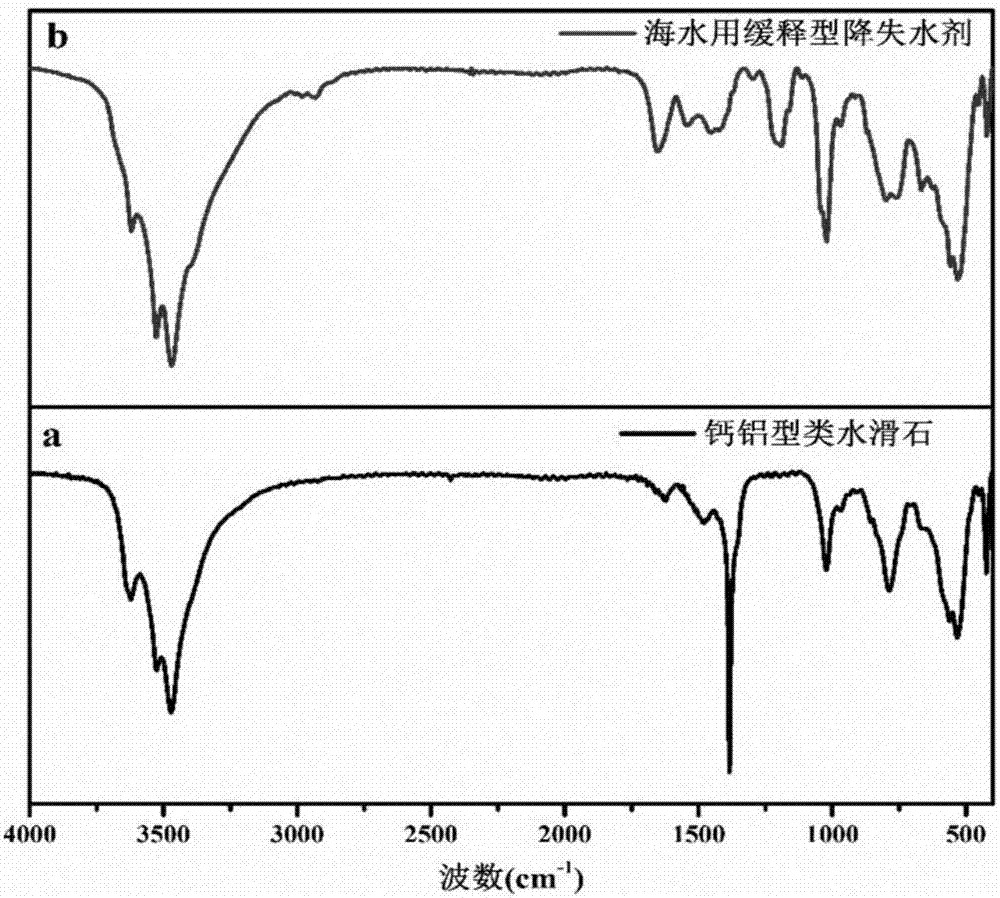

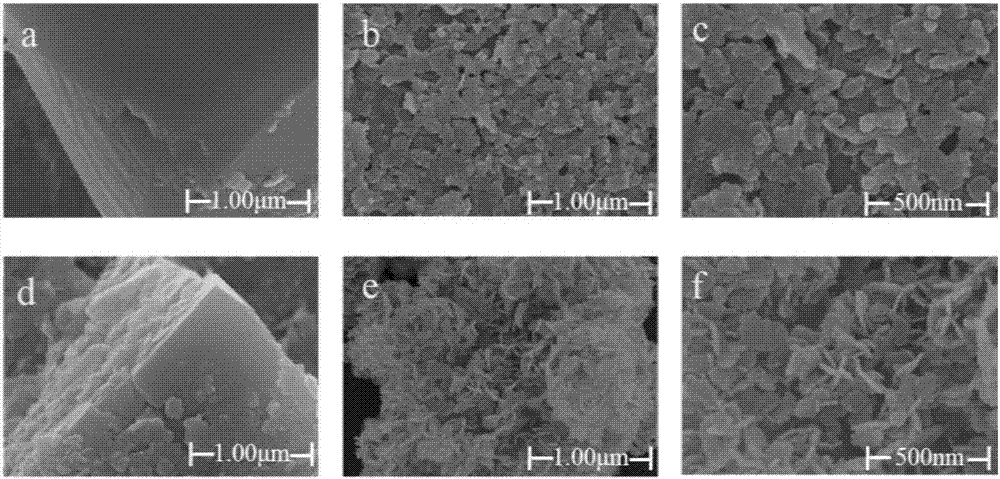

Method used

Image

Examples

preparation example Construction

[0036] A preparation method of a slow-release fluid loss reducer for seawater well cementing, comprising the steps of:

[0037] (1) Dissolve 25g of the monomer in 110mL of deionized water, stir well at room temperature, adjust the pH of the solution to 6 with sodium hydroxide; add ammonium persulfate accounting for 0.6% of the total mass of the monomer, and react under stirring at 70°C 4h, cooled to room temperature to obtain a quaternary anionic copolymer; the monomer is 78% by mass of 2-acrylamide-2-methylpropanesulfonic acid, 4% of maleic acid, N,N-dimethyl 15% acrylamide, 3% allyl polyethylene glycol;

[0038] The number average molecular weight of allyl polyethylene glycol is 600;

[0039] (2) Get 32g of mixed nitrates and dissolve them in 100mL deionized water to make solution A; the mixed nitrates are composed of Ca(N0 3 ) 2 .4H 2 0 and A1(N0 3 ) 3 .9H 2 0 composition; 15g of sodium mixture was dissolved in 100mL deionized water to form solution B; the sodium mix...

Embodiment 2

[0042] A preparation method of a slow-release fluid loss reducer for seawater well cementing, comprising the following steps:

[0043] (1) Dissolve 20g of the monomer in 110mL of deionized water, stir well at room temperature, adjust the pH of the solution to 7 with sodium hydroxide; add ammonium persulfate accounting for 0.4% of the total mass of the monomer, and react under stirring at 60°C 6h, cooled to room temperature to obtain a quaternary anionic copolymer; the monomer is 76% by mass of 2-acrylamide-2-methylpropanesulfonic acid, 5% of maleic acid, N,N-dimethyl 16% acrylamide, 3% allyl polyethylene glycol;

[0044] The number average molecular weight of allyl polyethylene glycol is 1200;

[0045] (2) Get 25g of mixed nitrates and dissolve them in 100mL deionized water to make solution A; the mixed nitrates are composed of Ca(N0 3 ) 2 .4H 2 0 and A1(N0 3 ) 3 .9H 2 0 composition; 10g of sodium mixture was dissolved in 100mL deionized water to form solution B; the so...

Embodiment 3

[0048] A preparation method of a slow-release fluid loss reducer for seawater well cementing, comprising the following steps:

[0049] (1) Dissolve 30 g of the monomer in 110 mL of deionized water, stir evenly at room temperature, adjust the pH of the solution to 4 with potassium hydroxide; add azobisisobutylamidine hydrochloride accounting for 0.8% of the total mass of the monomer, and 80°C, reacted for 2 hours under stirring, cooled to room temperature, and obtained a quaternary anionic copolymer; , composed of 14% N-dimethylacrylamide and 1% allyl polyethylene glycol;

[0050] The number average molecular weight of allyl polyethylene glycol is 1200;

[0051] (2) Get 40g of mixed nitrates and dissolve them in 100mL deionized water to make solution A; the mixed nitrates are composed of Ca(N0 3 ) 2 .4H 2 0 and A1(N0 3 ) 3 .9H 2 0 composition; 20g of sodium mixture was dissolved in 100mL deionized water to form solution B; the sodium mixture was composed of NaOH and NaNO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com