Pleated graphene fiber, graphene-fiber non-woven fabric and preparation methods of pleated graphene fiber and graphene-fiber non-woven fabric

A graphene fiber, non-woven technology, applied in the direction of chemical characteristics of fibers, textiles and papermaking, chemical post-processing of rayon, etc., can solve the problems that have not been reported, and achieve the effect of wide application prospect and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

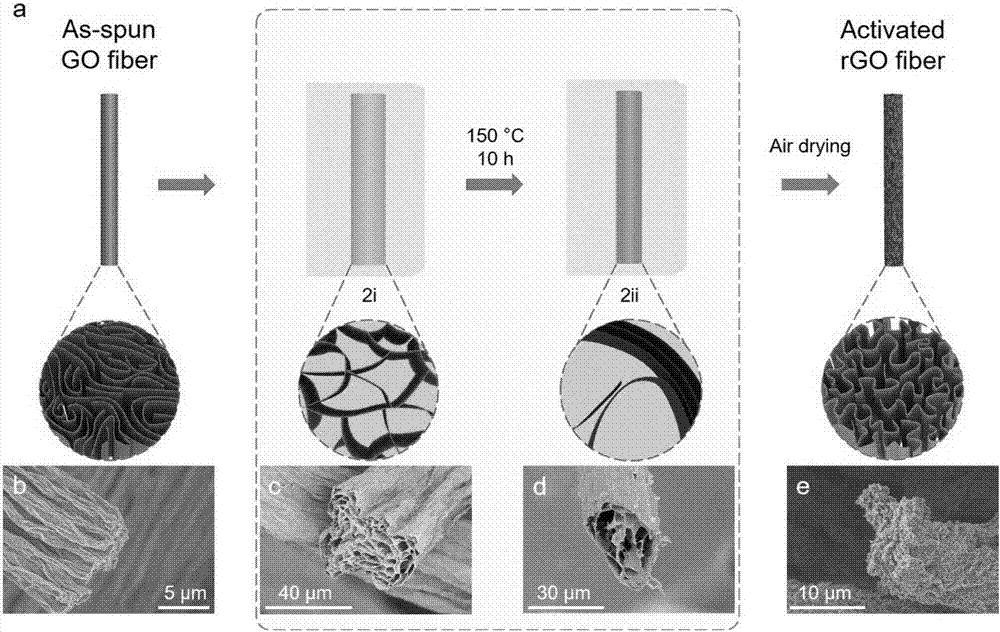

[0027] (1) The graphene oxide / water solution with a concentration of 5 mg / mL was used as the spinning solution, and the calcium chloride / water / ethanol mixture (mass ratio 20:300:100) was used as the coagulation bath for continuous wet spinning.

[0028] (2) The obtained graphene oxide fibers were left at room temperature for 12 hours, and then vacuum-dried at a temperature of 80° C. for 3 hours.

[0029] (3) Soak the fully dried graphene oxide fiber in a hydrothermal kettle filled with water for hydrothermal treatment, and the treatment condition is 200° C. for 12 hours.

[0030] (4) Obtain multi-fold graphene fibers after drying in air.

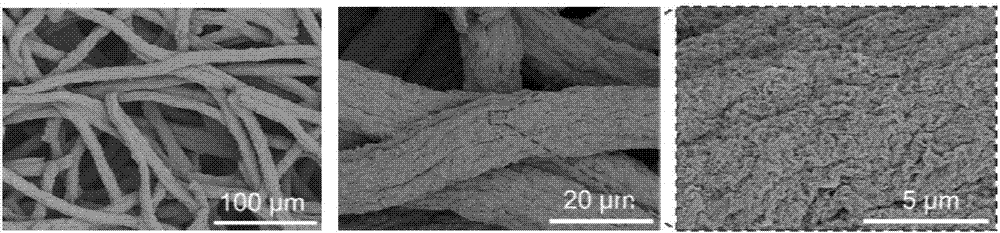

[0031] After the above steps, the obtained graphene fiber has an obvious wrinkled structure, the fiber strength is about 90MPa, and the conductivity is 102S / m.

Embodiment 2

[0033] (1) The graphene oxide / N, N-dimethylformamide solution with a concentration of 5 mg / mL was used as the spinning solution, and ethyl acetate was used as the coagulation bath for continuous wet spinning.

[0034] (2) The obtained graphene oxide fiber was placed at room temperature for 14 hours, and then vacuum-dried at 60° C. for 3 hours.

[0035] (3) Soak the fully dried graphene oxide fiber in a hydrothermal kettle filled with water for hydrothermal treatment, and the treatment condition is 150° C. for 12 hours.

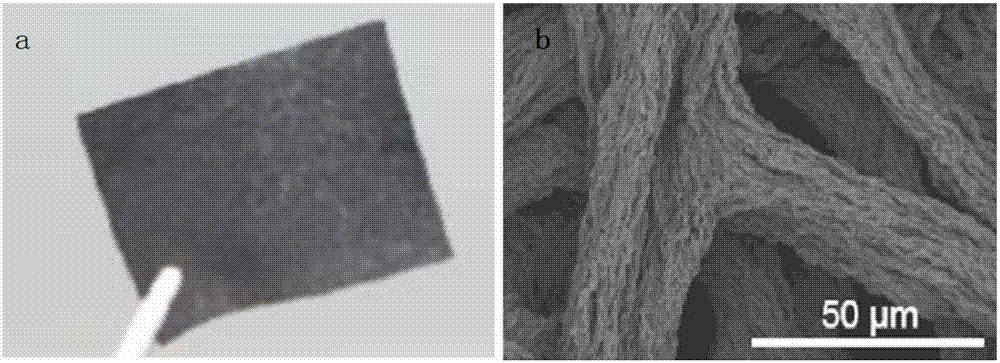

[0036] (4) Using a high-speed shear mixer with a rotating speed of 3000rpm, the graphene fibers after the hydrothermal treatment are crushed into short fibers with a length of 4 mm, deposited on a filter screen, and dried in the air to obtain a graphene fiber non-woven fabric.

[0037] After the above steps, the obtained graphene fiber non-woven fabric has a multi-level structure, the graphene fiber surface is rough, contains a large number of wrinkles and pro...

Embodiment 3

[0039] (1) The graphene oxide aqueous solution with a concentration of 15 mg / mL is used as the dispersion liquid, and the calcium chloride / water / ethanol mixture is used as the coagulation bath for continuous wet spinning.

[0040] (2) The obtained graphene oxide fiber was placed at room temperature for 15 hours, and then vacuum-dried at 100° C. for 3 hours.

[0041] (3) Soak the fully dried graphene oxide fiber in a hydrothermal kettle filled with water for hydrothermal treatment, and the treatment condition is 80° C. for 12 hours.

[0042] (4) Use a high-speed shear mixer to crush the graphene fibers after the hydrothermal treatment into short fibers at a speed of 5000rpm, and deposit them on a filter screen, and obtain a graphene fiber non-woven fabric with a multi-level structure after drying in the air.

[0043] (5) The dried graphene fiber non-woven fabric is further chemically reduced by using hydrazine hydrate.

[0044] After the above steps, the obtained graphene fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com