Backpressure and power matching hydraulic hybrid power control double-actuator system

A hydraulic actuator and hybrid power technology, which is applied to fluid pressure actuation system components, fluid pressure actuation devices, servo motors, etc., can solve the problems of increasing power source emissions and energy consumption, restricting popularization and application, and low efficiency , to achieve the effect of low emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

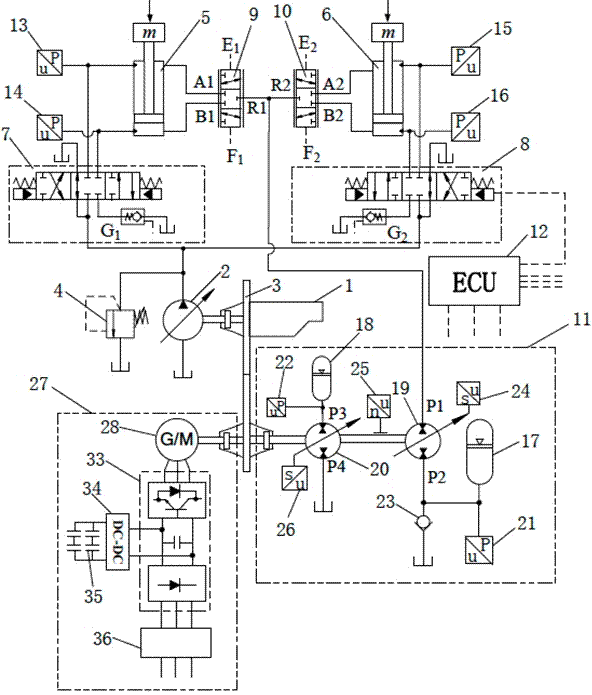

[0033] as attached figure 1 As shown, it is the embodiment 1 of the dual-actuator system for back pressure and power matching hydraulic hybrid control of the present invention, which includes an electric power control unit and a back pressure control unit connected to the transfer case, and controls the circuit principle of two hydraulic actuators . The system includes the power source 1 as an internal combustion engine, the main hydraulic pump 2 as a variable displacement hydraulic pump, the transfer case 3 as the main transmission torque, the speed ratio of each shaft is 1:1, and the set pressure of the safety valve 4 is 32 MPa , The first hydraulic actuator 5 is a hydraulic cylinder, the second hydraulic actuator 6 is a hydraulic cylinder, the first control valve 7, and the second control valve 8 are proportional multi-way valves with positive flow control. Its structural relationship is that a power control unit 27, a back pressure control unit 11 are further added, the c...

Embodiment 2

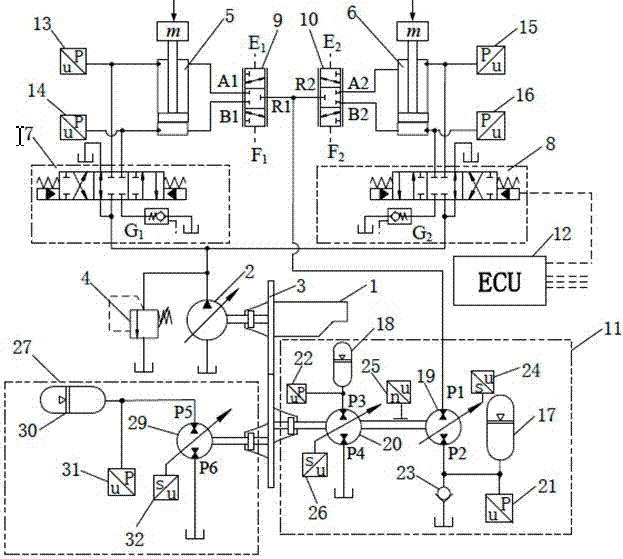

[0043] as attached figure 2 As shown, it is the embodiment 2 of the hydraulic hybrid control dual-actuator system for back pressure and power matching of the present invention, which includes a hydraulic power control unit and a back pressure control unit connected to the transfer case 3 to control the circuit principle of two hydraulic actuators .

[0044] The composition and connection relationship of this embodiment 2 are similar to those of embodiment 1, the difference is that the power regulation unit 27 adopts a hydraulic control method, and the power regulation unit 27 includes a power regulation hydraulic pump / motor 29, and an axial plunger structure is selected, Power regulation hydraulic accumulator 30 , seventh pressure sensor 31 , third displacement sensor 32 . The drive shaft of the power regulation hydraulic pump / motor 29 is directly connected to the transfer case 3, the oil port P5 of the power regulation hydraulic pump / motor 29 communicates with the working o...

Embodiment 3

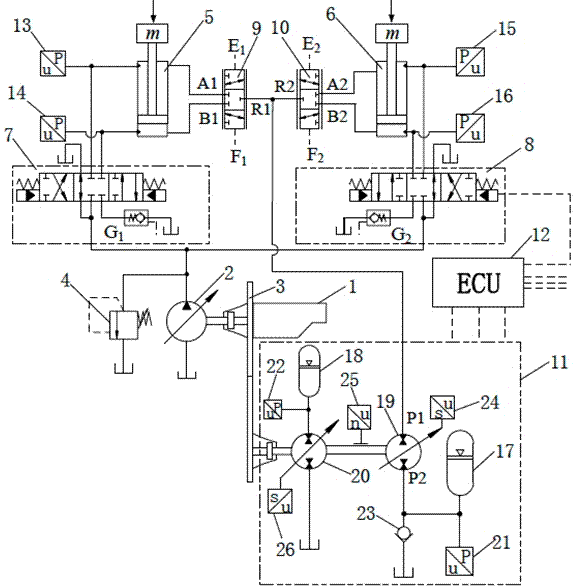

[0046] as attached image 3 Shown is the embodiment 3 of the back pressure and power matching hydraulic hybrid control dual actuator system of the present invention, which only uses the circuit principle of the back pressure control unit 11 connected to the transfer case 3 to control the two hydraulic actuators. The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the power control unit 27 is not included in the system, and the power source is an electric motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com