Preparation method for anti-aging polyester hot melt adhesive for electronic products

A technology for polyester hot melt adhesive and electronic products, which is applied in the directions of adhesives, polymer adhesive additives, rosin adhesives, etc. achieve good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

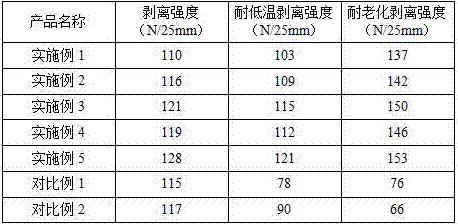

Examples

Embodiment 1

[0015] A method for preparing an aging-resistant polyester hot-melt adhesive for electronic products, comprising the following steps: (1) Weighing the following components by mass ratio: 15 parts of disproportionated rosin, 100 parts of toluene, 4 parts of thionyl chloride, triethylamine 3 parts, 0.01 part of hydroquinone, 12 parts of 2-ethylhexyl acrylate; (2) After dissolving disproportionated rosin with toluene, add thionyl chloride at the same time, react at 45°C for 8 hours, add triethylamine, Hydroquinone and 2-ethylhexyl acrylate were reacted at 70°C for 7 h, filtered, washed with water, and solvent removed to obtain a rosin tackifying resin; (3) Copolyester, rosin tackifying resin, α-Methylstyrene modified C 5 Petroleum resin, ethylene-vinyl acetate-vinyl alcohol terpolymer, and terpene resin were mixed according to the mass ratio of 40:24:10:8:12, stirred at 160°C at a speed of 60r / min for 10min, and extruded by a twin-screw Extrude and granulate to obtain polyester ...

Embodiment 2

[0017] A method for preparing an aging-resistant polyester hot-melt adhesive for electronic products, comprising the following steps: (1) Weighing the following components by mass ratio: 28 parts of disproportionated rosin, 40 parts of toluene, 12 parts of thionyl chloride, triethylamine 10 parts, 0.002 parts of hydroquinone, 6 parts of 2-ethylhexyl acrylate; (2) After dissolving disproportionated rosin with toluene, add thionyl chloride at the same time, react at 80°C for 3 hours, add triethylamine, Hydroquinone and 2-ethylhexyl acrylate were reacted at 85°C for 2 h, and the rosin tackifying resin was obtained after filtering, washing with water, and solvent removal; (3) copolyester, rosin tackifying resin, α-Methylstyrene modified C 5 Petroleum resin, ethylene-vinyl acetate-vinyl alcohol terpolymer, and terpene resin were mixed according to the mass ratio of 65:15:5:22:5, stirred at 160°C for 3 minutes at a speed of 100r / min, and extruded with a twin-screw Extrude and granu...

Embodiment 3

[0019] A method for preparing an aging-resistant polyester hot-melt adhesive for electronic products, comprising the following steps: (1) Weighing the following components by mass ratio: 18 parts of disproportionated rosin, 50 parts of toluene, 10 parts of thionyl chloride, triethylamine 5 parts, 0.008 parts of hydroquinone, 8 parts of 2-ethylhexyl acrylate; (2) After dissolving disproportionated rosin with toluene, add thionyl chloride at the same time, react at 55°C for 6 hours, add triethylamine, Hydroquinone, 2-ethylhexyl acrylate, react at 75°C for 6 hours, filter, wash with water, and remove solvent to obtain rosin tackifying resin; (3) Copolyester, rosin tackifying resin, α -Methyl styrene modified C 5 Petroleum resin, ethylene-vinyl acetate-vinyl alcohol terpolymer, and terpene resin were mixed at a mass ratio of 45:18:9:14:10, stirred at 160°C for 8 minutes at a speed of 70r / min, and extruded with a twin-screw Extrude and granulate to obtain polyester hot-melt granul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com