Inductor, manufacturing method of inducer, and forming die for pressing inductor

A technology of pressing molding and manufacturing methods, which is applied in the manufacture of inductors/transformers/magnets, inductors, fixed inductors, etc., and can solve problems affecting the performance of inductors, affecting the magnetic induction performance of inductors, and mold ejection cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

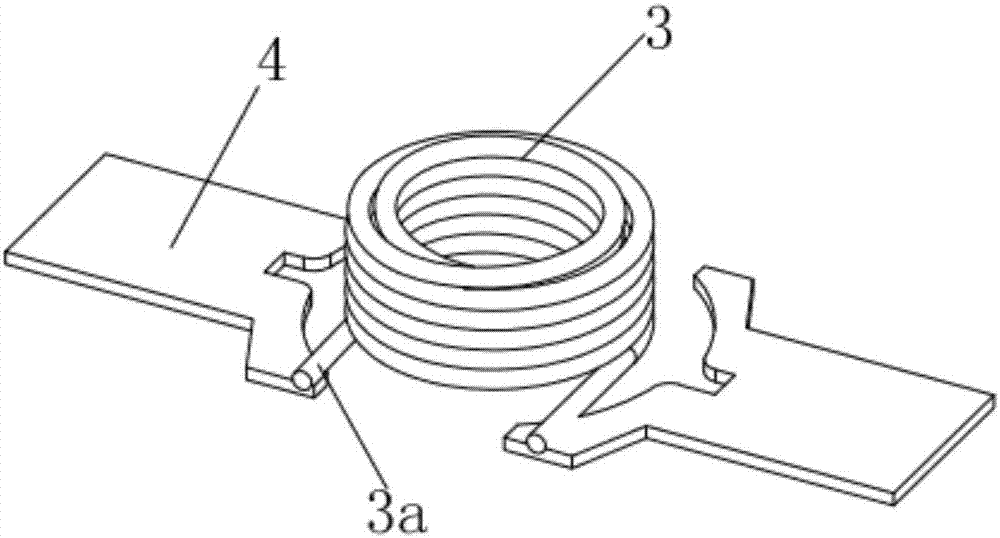

[0051] Such as Figure 10 As shown, an inductor includes a magnet and a coil 3, the magnet includes a magnet prefabricated part 2 and the magnet prefabricated part 2 nested with the coil 3 is placed in a molding die and added with a magnetic material and / or a non-magnetic material for compression molding The magnet press-molded part 1. In the present invention, the magnetic material and / or nonmagnetic material mixture includes carbonyl iron powder or alloy iron powder, resin and lubricant, wherein the weight of the carbonyl iron powder or alloy iron powder accounts for the weight of the magnetic material and / or nonmagnetic material mixture 95-97% of the total. In addition, the magnetic material and / or non-magnetic material can also be one of iron powder, sendust powder, high magnetic flux powder, permalloy powder, ferrite, amorphous and nanocrystalline alloy or any suitable material or Several kinds.

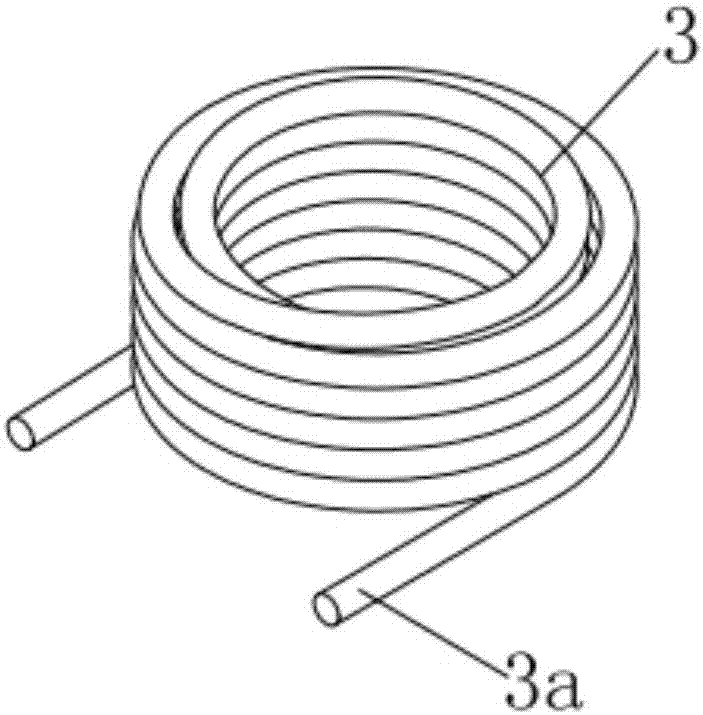

[0052] Such as figure 1 , figure 2As shown, the coil 3 is an air-core...

Embodiment 2

[0065] Such as Figure 11 As shown, an inductor includes a magnet and a coil 3, the magnet includes a magnet prefabricated part 2 and the magnet prefabricated part 2 nested with the coil 3 is placed in a molding die and added with a magnetic material and / or a non-magnetic material for compression molding The magnet press-molded part 1. In the present invention, the magnetic material and / or nonmagnetic material mixture includes carbonyl iron powder or alloy iron powder, resin and lubricant, wherein the weight of the carbonyl iron powder or alloy iron powder accounts for the weight of the magnetic material and / or nonmagnetic material mixture 95-97% of the total. In addition, the magnetic material and / or non-magnetic material can also be one of iron powder, sendust powder, high magnetic flux powder, permalloy powder, ferrite, amorphous and nanocrystalline alloy or any suitable material or Several kinds.

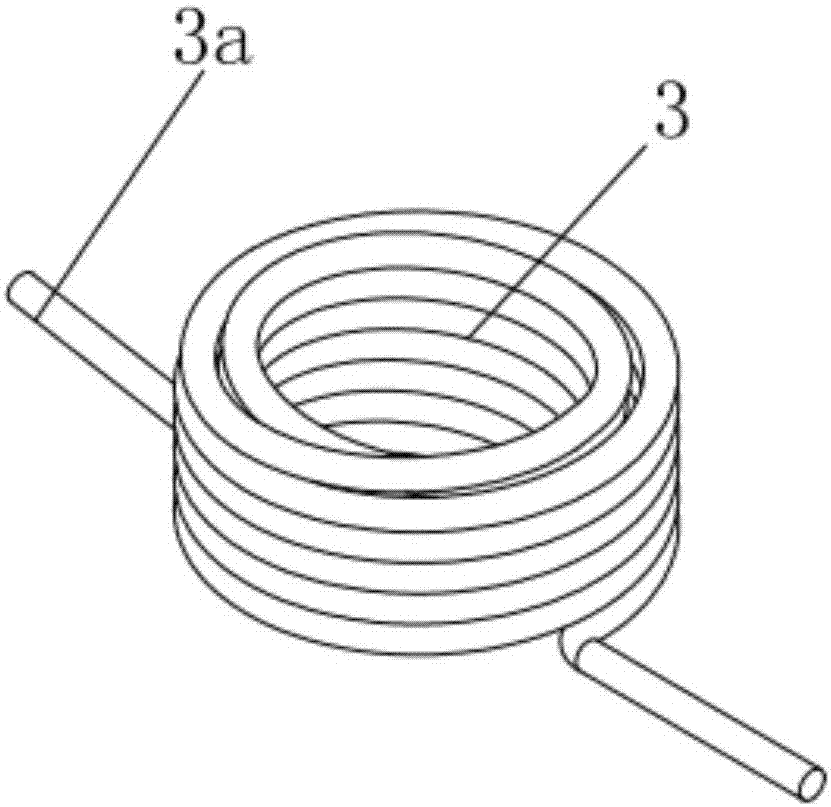

[0066] Such as image 3 , Figure 4 As shown, the coil 3 is an air-cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com