Light-cured 3D (three-dimensional) printing photosensitive resin, preparation method thereof and application of resin

A 3D printing and photosensitive resin technology, applied in the field of 3D printing, can solve problems such as complicated procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

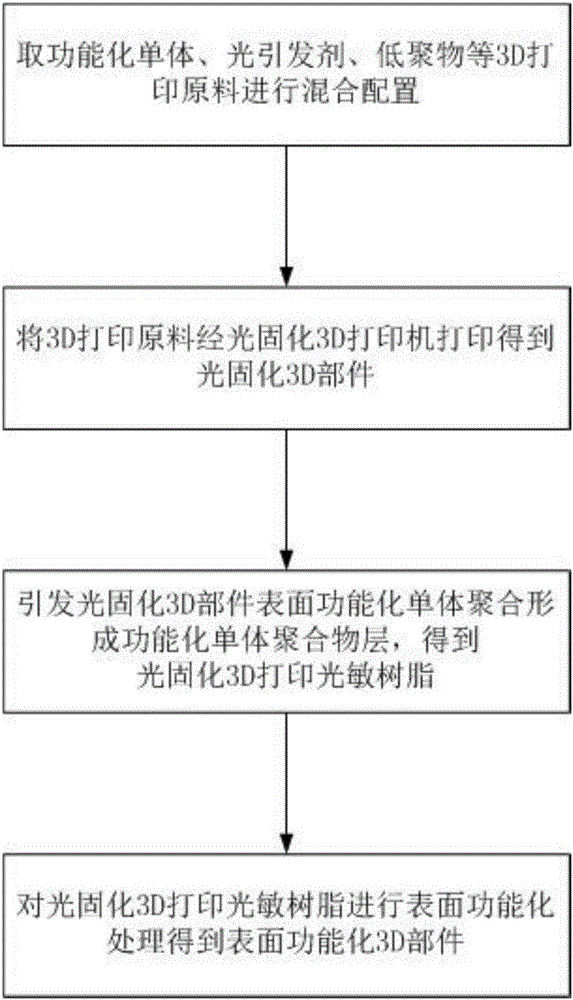

Method used

Image

Examples

Embodiment 1

[0048] A light-curing 3D printing photosensitive resin, which is made of the following components in parts by weight: 2 parts of functionalized monomers, 5 parts of photoinitiators, 40 parts of oligomers, 20 parts of reactive diluents and 1 part of additives . The functionalized monomer is catechol amine compound, specifically dopamine. The photoinitiator is (2,4,6-trimethylbenzoyl)diphenylphosphine oxide. The oligomer is epoxy acrylate. The reactive diluent is a vinyl ether monomer, specifically cyclohexyl-1,4-dimethanol monovinyl ether. Additives are pigments, stabilizers and surfactants. The pigment is an oily dye, the stabilizer is a light stabilizer, and the surfactant is a cationic surfactant.

Embodiment 2

[0050] A light-curing 3D printing photosensitive resin, made of the following components in parts by weight: 10 parts of functionalized monomers, 10 parts of photoinitiators, 50 parts of oligomers, 50 parts of reactive diluents and 30 parts of additives . The functionalized monomer is an amine compound of catechol, specifically 3,4-dihydroxy-β-phenethylamine hydrochloride. The photoinitiator is a diaryliodonium salt. The oligomer is urethane acrylate. The reactive diluent is an acrylate monomer, and the acrylate monomer is specifically:

[0051]

[0052] Among them, n is 1. The additives are pigments, stabilizers and surfactants. The pigment is an oily dye, the stabilizer is a light stabilizer, and the surfactant is an anionic surfactant.

Embodiment 3

[0054] A light-curing 3D printing photosensitive resin, which is made of the following components in parts by weight: 5 parts of functionalized monomers, 8 parts of photoinitiators, 45 parts of oligomers, 35 parts of reactive diluents and 15 parts of additives . The functionalized monomer is catechol amine compound, specifically L-3-(3,4-dihydroxyphenyl)alanine. The photoinitiator is isopropylthioxanthone. The oligomer is polyester acrylate. The reactive diluent is a vinyl ether monomer, specifically tri(ethylene glycol) divinyl ether. The additives are pigments, stabilizers and surfactants. The pigment is an oily dye, the stabilizer is a light stabilizer, and the surfactant is a nonionic surfactant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com