Preservative film and preparation method thereof

A technology of plastic wrap and barrier coating, which is applied in the field of plastic wrap and its preparation, can solve the problems of insufficient water vapor and air barrier ability, unfriendly human body and environment, poor compactness of plastic wrap, etc., and achieve good anti-mold and bactericidal effect, Guaranteed preservation effect, good ability to block water vapor and air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

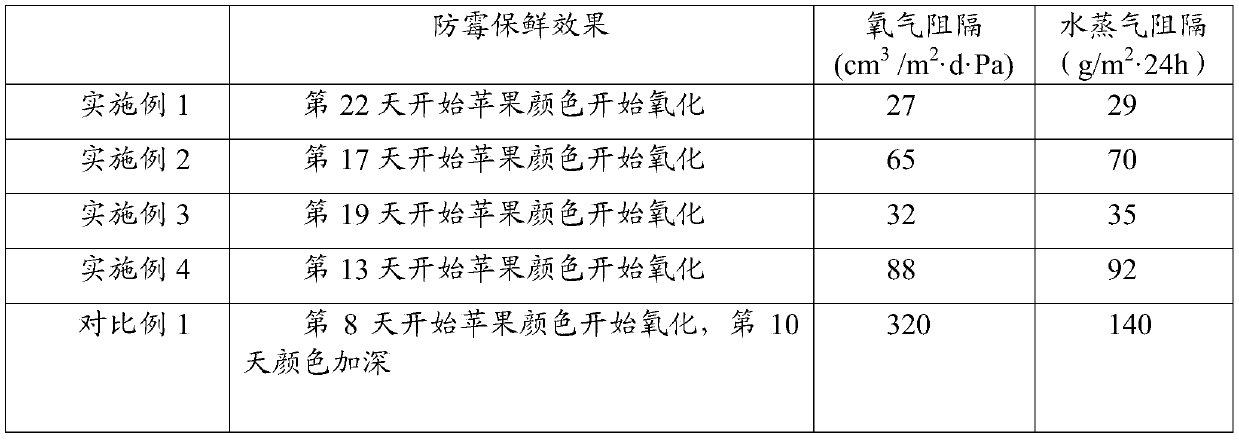

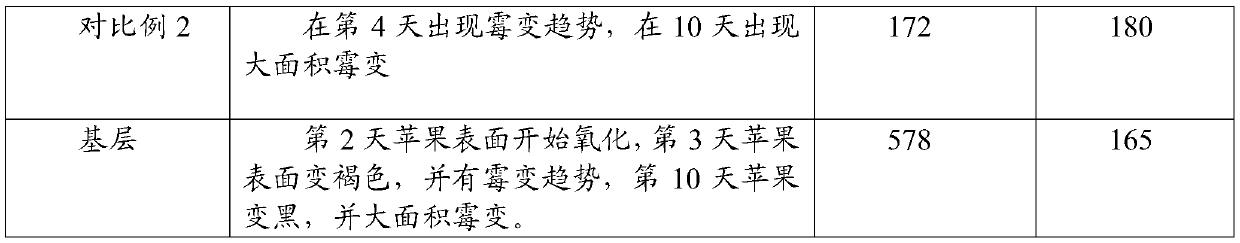

Examples

preparation example Construction

[0033] A method for preparing a fresh-keeping film according to an embodiment of the present invention includes the following steps S1-S3:

[0034] S1. Obtain the base layer, and the base layer includes the opposite first side and the second side;

[0035] S2, apply a mildew-proof coating on the first side.

[0036] S3. Coating a barrier coating on the second side to obtain a fresh-keeping film.

[0037] Optionally, the base layer is polyethylene terephthalate and / or polyamide, the antifungal coating comprises 65%-85% resin and 15%-35% antifungal agent, and the barrier coating comprises 5%-40%. % polyvinyl alcohol, 5% to 25% agar, 0.05% to 5% borax, 0.05% to 5% boric acid and 30% to 85% water. It can be understood that the specific types of the base layer, the anti-mildew coating and the barrier coating are not limited to this. applicable to the present invention.

[0038] Optionally, the resin in the anti-mildew coating is partially hydrolyzed ethylene-vinyl acetate copol...

Embodiment 1

[0066] A base layer is obtained, the base layer includes opposing first and second sides.

[0067] After the base layer goes through the unwinding step, the anti-mold coating is applied on the first side by forward coating, and the barrier coating is applied on the second side by reverse coating, and the dry coating amount is 2.2g / m2 2 , the coating speed is 100m / min.

[0068] Then use a smoothing brush to smooth the anti-mildew coating and the barrier coating, and the smoothing brush is perpendicular to the contact surface when it is in contact with the anti-mildew coating or the blocking coating, and the pressure of the smoothing brush is 3kg.

[0069] The anti-mildew coating and barrier coating on the surface of the base layer are dried with a suspension oven. The temperature field of the suspension oven from the inlet end to the outlet end is 45°C, 110°C, 140°C, 150°C, and 110°C.

[0070] The surface of the anti-mildew coating and the surface of the barrier coating are ho...

Embodiment 2

[0072] The preparation method is basically the same as that of Example 1, except that the first side and the second side are coated with a mildew-proof coating and a barrier coating respectively in a forward coating manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com