Preparation method of expansible thermoplastic graphene porous carbon material

A porous carbon material and graphene technology, applied in the field of materials, can solve the problems of increased thermal conductivity of sheet materials, and achieve the effects of high elasticity, strong practicability, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

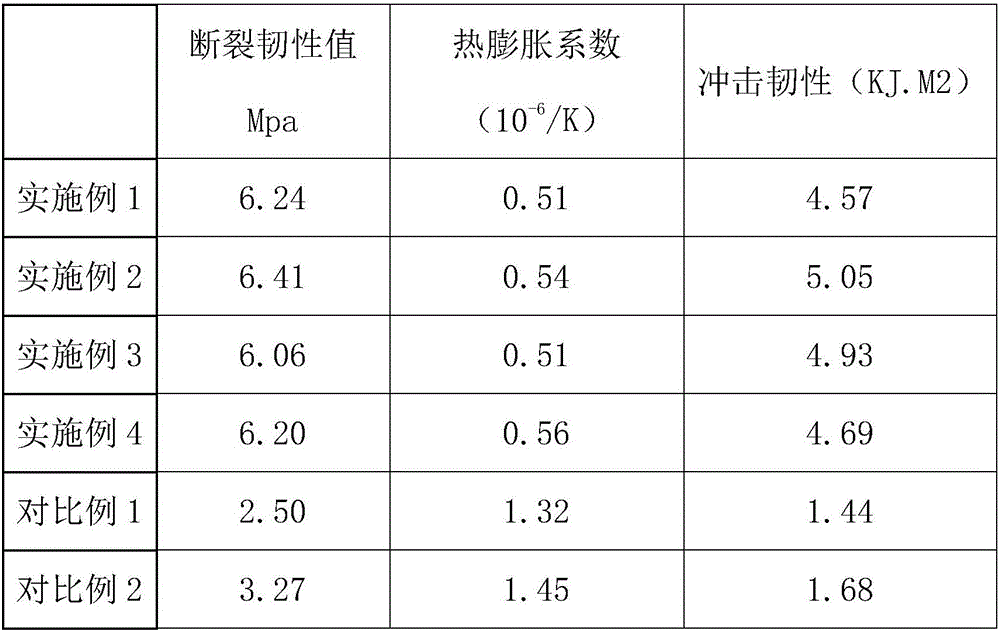

Examples

Embodiment 1

[0024] (1) Mix 20 parts of elastic polymer matrix and 1 part of vinyltrichlorosilane evenly and put them into a vacuum furnace for high-temperature kneading. The vacuum pressure in the furnace is 5*10-2Pa, and the reaction temperature is 780°C;

[0025] (2) Mix 7 parts of graphene and 1 part of dimethyl silicone oil, the ball-to-material ratio is 2:105, add it into a high-speed ball mill and mill it at a speed of 1800 rpm for 2 hours, sieve and sort, and the sieve aperture is 3000 mesh ;

[0026] (3) after the Graphene dispersion powder that step (2) obtains mixes with the metal powder mixture with the mass ratio of 15:1, for subsequent use;

[0027] (4) inject the elastic polymer solution prepared in step (1) into a twin-screw extruder, extrude, press mold, demold, and set aside, wherein the screw temperature is 220 ° C, and the screw speed is 1000 rpm;

[0028] (5) inject the graphene metal mixed powder in the step (3) into the pressure sprayer, be 20MPa with the spray pres...

Embodiment 2

[0031] (1) Mix 22 parts of elastic polymer matrix and 1 part of γ-chloropropyl trichlorosilane evenly and put them into a vacuum furnace for high-temperature kneading. The vacuum pressure in the furnace is 5*10-2Pa, and the reaction temperature is 800°C;

[0032] (2) Mix 9 parts of graphene and 2 parts of dimethyl silicone oil, the ball-to-material ratio is 2:105, add it to a high-speed ball mill and mill it at a speed of 1800 rpm for 2.5 hours, sieve and sort, and the sieve aperture is 3000 head;

[0033] (3) after the Graphene dispersion powder that step (2) obtains mixes with the metal powder mixture with the mass ratio of 15:1, for subsequent use;

[0034] (4) inject the elastic polymer solution prepared in step (1) into a twin-screw extruder, extrude, press mold, demold, and set aside, wherein the screw temperature is 230°C, and the screw speed is 1000 rpm;

[0035] (5) inject the graphene metal mixed powder in the step (3) into the pressure sprayer, be 20MPa with the sp...

Embodiment 3

[0038] (1) Mix 24 parts of the elastic polymer matrix and 2 parts of bis-(3-triethoxysilylpropyl)tetrasulfide evenly and add them to the vacuum furnace for high temperature mixing. The vacuum pressure in the furnace is 5*10-2Pa, and the reaction temperature is 820°C;

[0039] (2) Mix 11 parts of graphene and 3 parts of dimethyl silicone oil, the ball-to-material ratio is 2:105, add it into a high-speed ball mill and mill it at a speed of 1800 rpm for 3 hours, sieve and sort, and the sieve aperture is 3000 mesh ;

[0040] (3) after the Graphene dispersion powder that step (2) obtains mixes with the metal powder mixture with the mass ratio of 15:1, for subsequent use;

[0041] (4) inject the elastic polymer solution prepared in step (1) into a twin-screw extruder, extrude, press mold, demold, and set aside, wherein the screw temperature is 250°C, and the screw speed is 1000 rpm;

[0042] (5) inject the graphene metal mixed powder in the step (3) into the pressure sprayer, be 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com