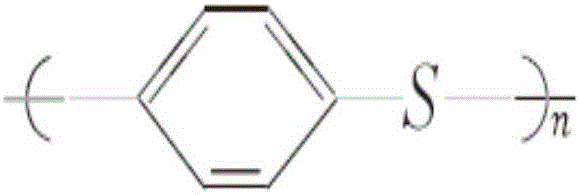

Polyphenylene sulfide compound for environment-friendly electroplating and preparation method thereof

A technology of polyphenylene sulfide and polyphenylene sulfide resin is applied in the field of environmentally friendly electroplating polyphenylene sulfide compound and its preparation, which can solve the problems of allergies, lasting environmental hazards, and no ABS in market applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

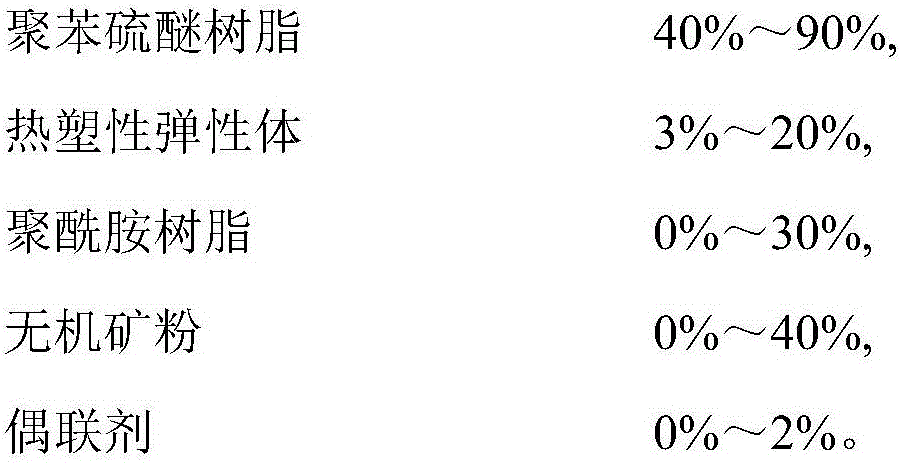

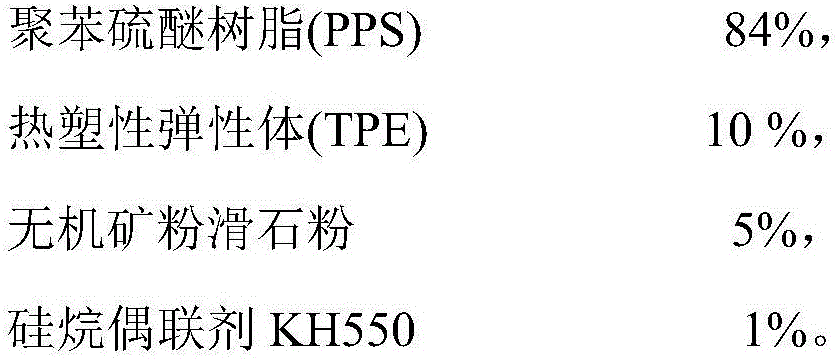

[0089] A polyphenylene sulfide compound used for environmentally friendly electroplating, including the following raw materials by weight percentage (the total weight of raw materials is 10KG):

[0090]

[0091] The above-mentioned preparation method of polyphenylene sulfide compound for environmental protection electroplating includes the following steps:

[0092] (1) PPS and TPE are added to the twin-screw extruder through the main feeder for melt polymerization, and the blend is obtained by drawing and pelletizing, which is ready for use;

[0093] (2) Add the inorganic mineral powder talc powder to the high-mixer, wait until the temperature of the inorganic mineral powder talc powder is increased to 105°C, then add the silane coupling agent KH550 for reaction, the reaction time is 10 minutes, take it out and set it aside;

[0094] (3) The blend obtained in step (1) is added to the twin-screw extruder through the main feeder, and the inorganic mineral powder talc treated in step (2) ...

Embodiment 2

[0096] A polyphenylene sulfide compound used for environmentally friendly electroplating, including the following raw materials by weight percentage (the total weight of raw materials is 10KG):

[0097]

[0098] The above-mentioned preparation method of polyphenylene sulfide compound for environmental protection electroplating includes the following steps:

[0099] (1) PPS and TPO are added to the twin-screw extruder through the main feeder for melt polymerization, and the blend is obtained by drawing and pelletizing, which is ready for use;

[0100] (2) Add the inorganic mineral powder alumina to the high mixer, wait until the temperature of the inorganic mineral powder alumina is increased to 110°C, then add the silane coupling agent KH550 to react, the reaction time is 15 minutes, take it out for use;

[0101] (3) The blend obtained in step (1) is added to the twin-screw extruder through the main feeder, and the inorganic mineral powder alumina processed in step (2) is added to the ...

Embodiment 3

[0103] A polyphenylene sulfide compound used for environmentally friendly electroplating, including the following raw materials by weight percentage (the total weight of raw materials is 10KG):

[0104]

[0105] The above-mentioned preparation method of polyphenylene sulfide compound for environmental protection electroplating includes the following steps:

[0106] (1) PPS, PA6 and TPU are added to the internal mixer through the main feeder for melt polymerization to obtain a blend for use;

[0107] (2) Add the inorganic mineral powdered silica to the high-mixer, wait until the temperature of the inorganic mineral powdered silica is increased to 105°C, then add the silane coupling agent KH550 for reaction, the reaction time is 20 minutes, take it out for use;

[0108] (3) The blend obtained in step (1) is added to the twin-screw extruder through the main feeder, and the inorganic mineral powder silica processed in step (2) is added to the side feeder at the same time, after mixing , T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com