Underwater anti-impact coating with rapid curing function

A fast-curing, impact-resistant technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems that are not related to underwater structures and ship applications, are not suitable for large-scale promotion and application, and graphene increases the cost. To shorten the gel time, extend the time, improve the effect of tear resistance and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Fast-curing underwater impact-resistant coatings:

[0038] Prepare component A:

[0039] Take 100kg of polyoxypropylene ether glycol with a molecular weight of 1000, place it in a container with stirring, heating and vacuum, raise the temperature to 120°C under stirring, start vacuum dehydration at -0.095MPa, and maintain the temperature and pressure for 2 hours Finally, the pressure is released, the temperature drops below 60°C, and 126kg of MDI50 is added dropwise, and the temperature is kept below 60°C during the dropwise addition. After the dropwise addition, raise the temperature to 90~95°C and keep it for 2 hours, then lower the temperature, vacuumize and remove air bubbles, and then pack into barrels. The NCO content of this prepolymer is 15%.

[0040] Prepare B component:

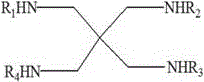

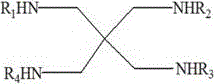

[0041] 61.3kg amino-terminated polyether D2000, 5kg amino-terminated polyether T403, 3.9kg amino-terminated polyether D400, 14kg liquid chain extender E100, 10kg liquid chain extender UNIL...

Embodiment 2

[0044] Prepare component A:

[0045]Take 90kg of polyoxypropylene ether glycol with a molecular weight of 2000 and 10kg of hydroxyl-terminated polybutadiene with a molecular weight of 1650 in a container with stirring, heating and vacuum, and raise the temperature to 110~120°C under stirring, and start at - Vacuum dehydration at 0.095MPa, maintain the temperature and pressure for 1~2 hours, release the pressure, the temperature drops below 60°C, add 143kg of MDI50 dropwise, and keep the temperature not exceeding 60°C during the dropping process. After the dropwise addition, raise the temperature to 90~100°C and keep it for 2 hours, then cool down, vacuumize and remove air bubbles, and then pack into barrels. The NCO content of this prepolymer is 18%.

[0046] Prepare B component:

[0047] 44.3kg of amino-terminated polyether D2000, 5.1kg of amino-terminated polyether T403, 30kg of liquid chain extender E300, 15.1kg of liquid chain extender UNILINK4200 and N-methyl-N 2 – Add...

Embodiment 3

[0050] Prepare component A:

[0051] Take 100kg of polytetrahydrofuran ether glycol with a molecular weight of 2000 in a container with stirring, heating and vacuum, raise the temperature to 115~120°C under stirring, start vacuum dehydration at -0.095MPa, and maintain the temperature and pressure for 1~2 Hours later, the pressure was released, the temperature dropped below 60°C, and 124.6kg of diphenylmethane-4,4 was added dropwise , -Diisocyanate and 53.4kg diphenylmethane-2,4 , - a mixture of diisocyanates, the temperature of which does not exceed 60°C during the dropwise addition. After the dropwise addition, raise the temperature to 90~100°C and keep it for 2 hours, then cool down, vacuumize and remove air bubbles, and then pack into barrels. The NCO content of this prepolymer is 20%.

[0052] Prepare B component:

[0053] 43.97kg amino-terminated polyether D2000, 3kg amino-terminated polyether T403, 4kg amino-terminated polyether D400, 26.9kg liquid chain extender E10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com