Graphene nano silver-copper paste

A nano-silver and graphene technology, applied in the field of electronic information, can solve the problems of easy and irreversible stacking, poor dispersion, etc., and achieve the effects of strong adaptability, low cost, and avoiding electron migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

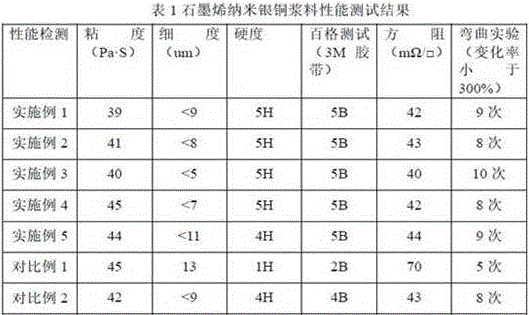

Examples

Embodiment 1

[0037] S1. Add 5mg / ml graphene, 10mg / ml nano-silver, 120mg / ml cetyltrimethylammonium bromide, KH550 coupling agent 30mg / ml into N,N-dimethylformamide, heat to 50°C, ultrasonic treatment for 2 hours to obtain a graphene nano-silver dispersion;

[0038] S2. Add 8 parts of epoxy resin to 33 parts of N,N-dimethylformamide, heat to dissolve, add 5 parts of graphene nano-silver dispersion, 30 parts of copper powder, 0.3 parts of nano-nickel powder and a mixture of nano-calcium carbonate , constant temperature and high-speed stirring, three-roll rolling mill rolling 5 times, and filtering through a 400-mesh sieve.

Embodiment 2

[0040] S1. Add 8mg / ml graphene, 12mg / ml nano-silver, 220mg / ml hexadecyltrimethylammonium bromide, KH550 coupling agent 40mg / ml into N,N-dimethylformamide, heat to 60°C, ultrasonic treatment for 2 hours to obtain a graphene nano-silver dispersion;

[0041] S2. 9 parts of epoxy resins are added in 45 parts of N,N-dimethylformamide, heat to dissolve, add 9 parts of graphene nano-silver dispersion liquid, 36 parts of copper powder, 0.5 part of nano-nickel powder and nano-calcium carbonate The mixture was stirred at constant temperature and high speed, rolled by a three-roll mill for 5 times, and filtered through a 400-mesh sieve.

Embodiment 3

[0043] S1. Add 11mg / ml graphene, 15mg / ml nano-silver, 330mg / ml hexadecyltrimethylammonium bromide, and 51mg / ml silane coupling agent into N,N-dimethylformamide, heat To 68 ° C, ultrasonic treatment for 2 hours, to obtain graphene nano-silver dispersion;

[0044] S2. Add 10 parts of epoxy resin to 51 parts of N,N-dimethylformamide, heat and dissolve, add 10 parts of graphene nano-silver dispersion, 40 parts of copper powder, 1 part of nano-nickel powder and nano-calcium carbonate The mixture was stirred at constant temperature and high speed, rolled by a three-roll mill for 8 times, and filtered through a 400-mesh sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com