Self-cleaning type air filter membrane and manufacturing method thereof

An air filtration and self-cleaning technology, which is applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve problems such as difficult, high-efficiency, low-resistance, and filtration of ultrafine particles, and achieve low cost, simple preparation method, high-efficiency self-cleaning The effect of cleaning and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

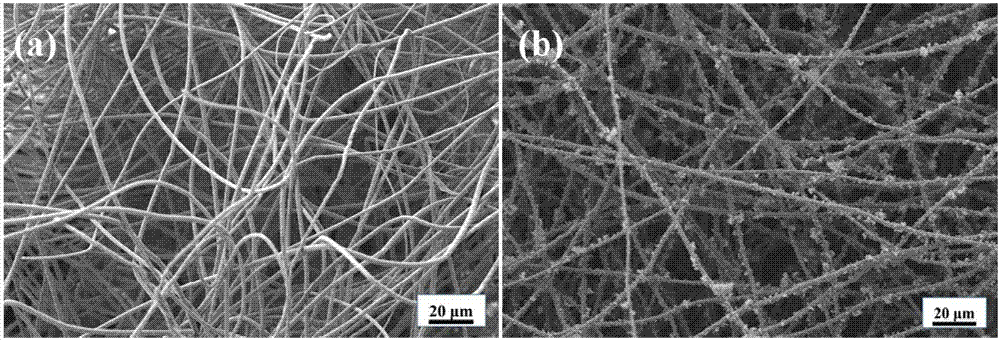

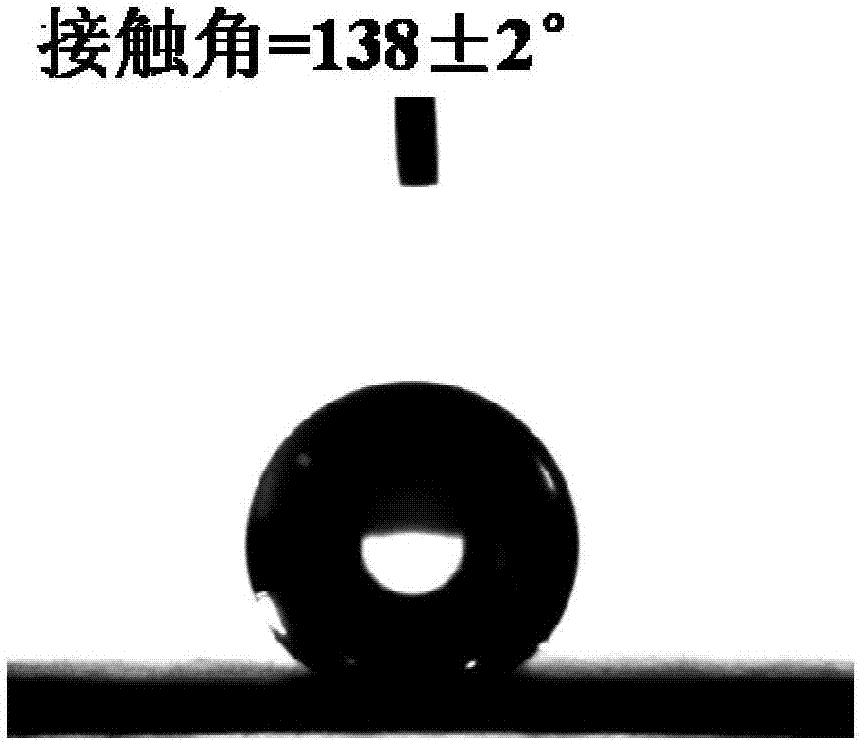

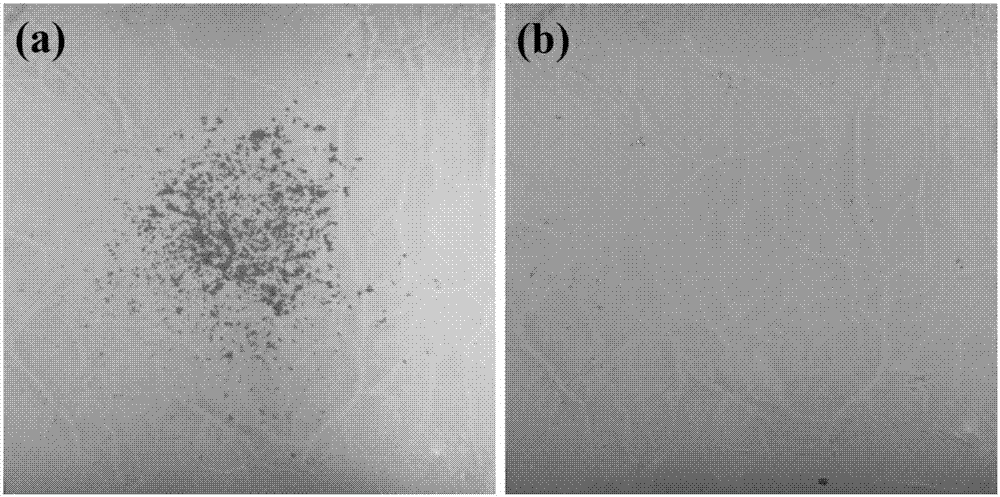

[0022] In this example, an electrospun polyacrylonitrile fiber membrane PAN was composited with dichlorodimethylsilane-modified silica nanoparticles to prepare a self-cleaning air filter membrane. Specific steps are as follows:

[0023] (1) Preparation of electrospun polyacrylonitrile fiber membrane:

[0024] Take polyacrylonitrile powder, dissolve it in the organic solvent N,N-dimethylformamide, stir sufficiently to dissolve the polyacrylonitrile, and prepare a transparent and clear polyacrylonitrile solution with a mass concentration of 11%;

[0025] The electrospun polyacrylonitrile fiber membrane was obtained by electrospinning electrospinning technology using polyacrylonitrile solution as the spinning solution. The optimal electrospinning process was as follows: the injection rate was 1.0mL / h, the electrospinning voltage was 13kV, and the collection distance was 15cm, aluminum foil as a conductive collection device;

[0026] (2) preparing silica nanoparticles modified w...

Embodiment 2

[0032] In this example, a self-cleaning air filter membrane was prepared by compounding electrospun polystyrene fiber membrane PS with dichlorodimethylsilane-modified silica nanoparticles. Specific steps are as follows:

[0033] (1) Preparation of electrospun polystyrene fiber membrane:

[0034] Take polystyrene particles, dissolve them in the organic solvent N,N-dimethylformamide, stir well to dissolve the polystyrene, and prepare a transparent and clear polystyrene solution with a mass concentration of 11%;

[0035] The polystyrene solution was used as the spinning solution to obtain the electrospun polystyrene fiber membrane by electrospinning technology. The optimal process of electrospinning is: the injection rate is 1.0mL / h, the electrospinning voltage is 14kV, and the collection distance is 22cm, copper mesh as a conductive collection device;

[0036] (2) preparing silica nanoparticles modified with dichlorodimethylsilane into an ethanol suspension with a mass concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com