Solvothermal preparation method of regular-octahedral calcium sulfide particles

An octahedral and solvothermal technology, applied in the direction of magnesium/calcium/strontium/barium sulfide/polysulfide, etc., can solve the problems of harmful gas leakage, low purity of CaS, high reaction temperature, etc., and achieve uniform scale, high purity, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0041] (1) Prepare the solution: take 0.222g of calcium chloride through a 100-mesh sieve and place it in a conical flask, add 20ml of ethylenediamine to form the first solution; feed nitrogen into the conical flask, drain the air, and let it stand stand-by;

[0042] (2) Add chelating agent: add 0.606g of L-cysteine and 0.204g of EDTA respectively in the first solution, while constantly stirring, Ca 2+ Chelate with a chelating agent to obtain a second solution; feed nitrogen gas, and sonicate for 30 minutes at a power of 300W;

[0043] (3) Preparation of reaction solution: Add 0.064 g of sulfur element and 0.4 ml of hydrazine hydrate monohydrate into a conical flask containing 60 ml of ethylenediamine to obtain a third solution; then, sonicate for 30 min under 300 W ultrasonic conditions.

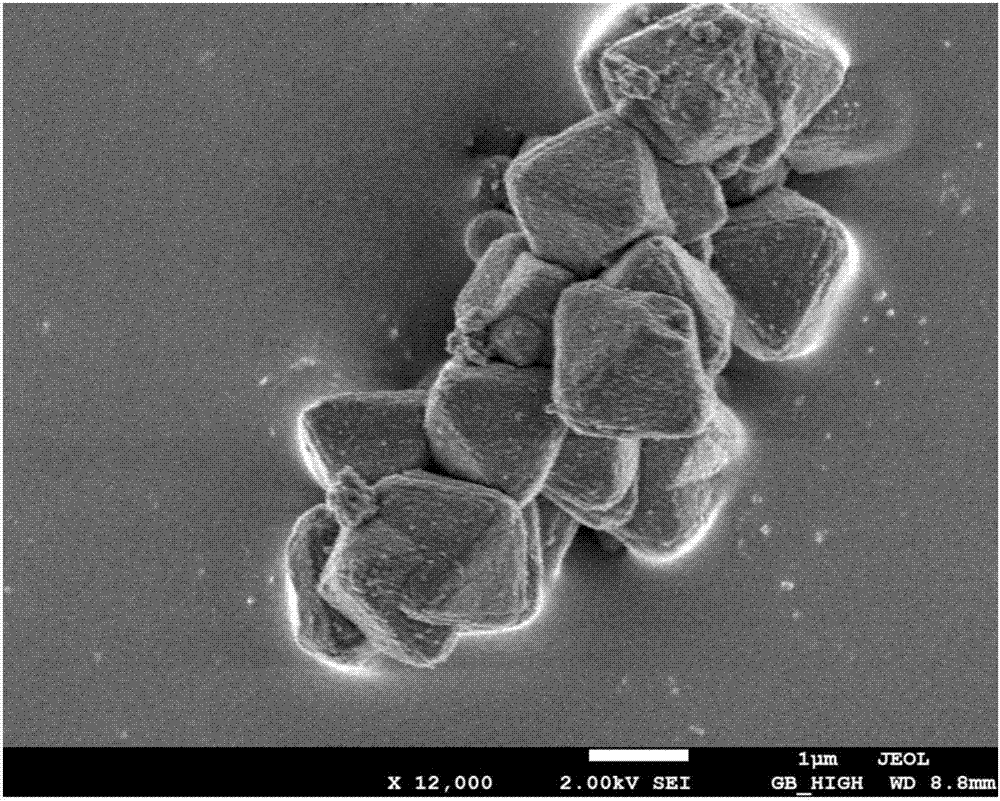

[0044] (4) Reaction: Pour the second solution and the third solution into a 100ml polytetrafluoroethylene lining at the same time, place the lining in the iron body at 180° C. for 72 hou...

comparative example 1

[0048] (1) Preparation of solution: Dissolve 0.222g of calcium chloride in 20ml of ethylenediamine; then pass nitrogen gas to isolate the contact with air; place the solution in an ultrasonic generator and ultrasonicate for 30min under the condition of 300W ultrasonic power to form a mixed solution.

[0049] (2) Preparation of reaction solution: Mix 0.064 g of sulfur element and 60 ml of ethylenediamine in a conical flask, then pass nitrogen gas again, and sonicate for 30 min under 300 W ultrasonic conditions.

[0050] (3) Reaction: Pour the above solution into a hydrothermal reaction kettle and keep it warm for 20 hours at 180° C., so as to observe the development process of CaS.

[0051] (4) Isolate the product: cool down the above solution naturally, open the reaction kettle by hand, collect the supernatant for later use, filter through absolute ethanol, wash, and dry to obtain a solid powder.

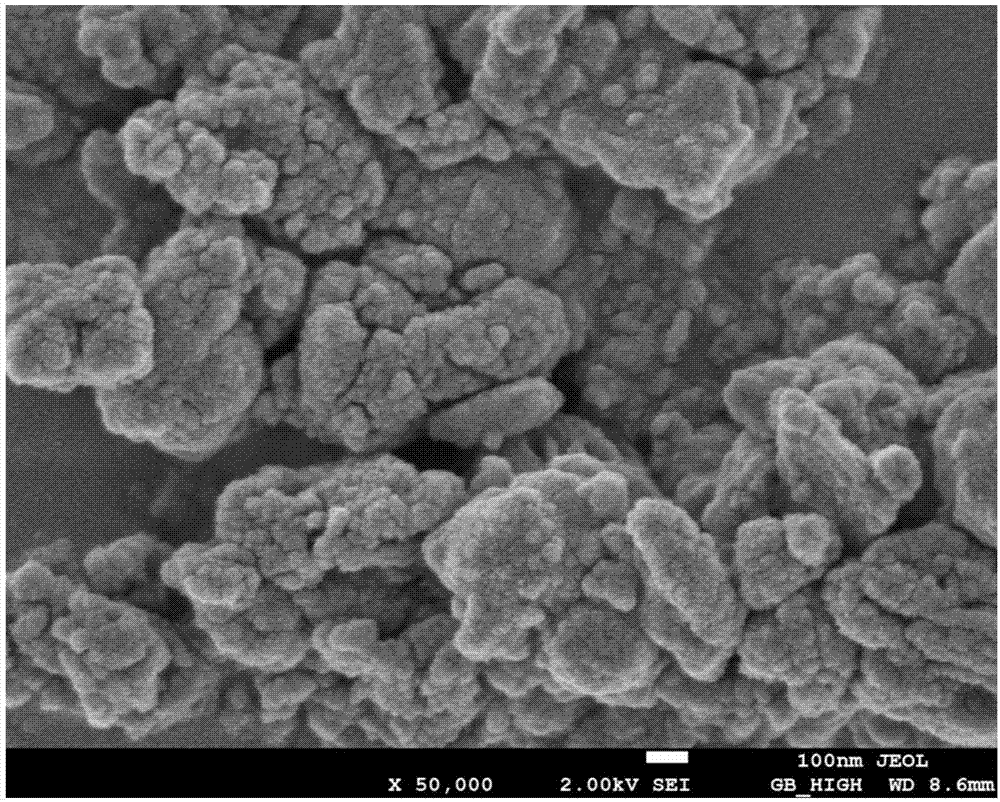

[0052] Scanning electron micrographs of CaS powders are shown in figure 2 , i...

comparative example 2

[0054] (1) Prepare the solution: add 20ml of ethylenediamine to the conical flask of 0.222g of calcium chloride crossing 100 mesh sieves; then, feed nitrogen to isolate the contact with the air; Ultrasonic 30min under the condition of 300W ultrasonic power, so that calcium chloride is uniformly dispersed in the solvent.

[0055] (2) Preparation of reaction solution: add 0.064g sulfur element to the conical flask containing 60ml ethylenediamine, the color of the solution changes, indicating that the sulfur element is converted into S 2- , Ultrasonic 30min under 300W ultrasonic conditions.

[0056] (3) Reaction: Pour the above two solutions into a hydrothermal reaction kettle, and keep the temperature at 180°C for 72 hours to make the reaction fully proceed.

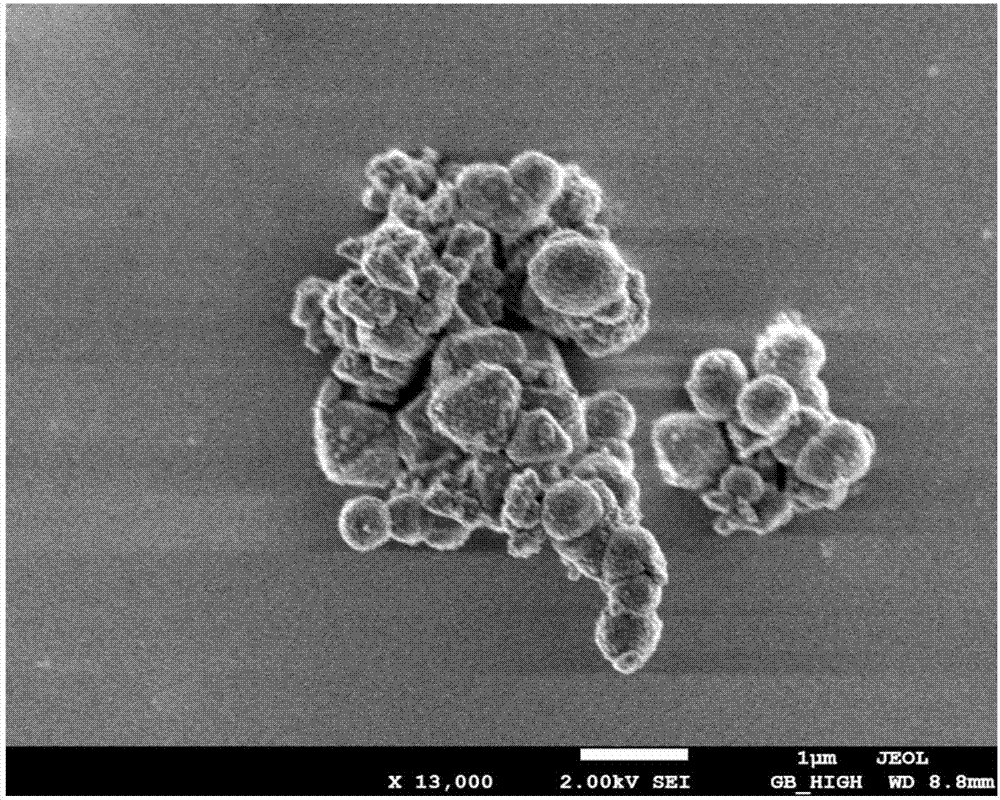

[0057] (4) Isolate the product: cool down the above solution naturally, pour the upper layer of ethylenediamine solution into a waste liquid bottle for recycling; filter and wash with absolute ethanol, and then dry it in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com