Preparation method of zirconium oxide-forsterite composite material with high strength and density

A technology of forsterite and composite materials, which is applied in the field of refractory materials, can solve problems affecting the application of forsterite, poor high-temperature performance of finished products, complicated preparation methods, etc., and achieve the effects of being conducive to industrial promotion, high refractoriness, and stable volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

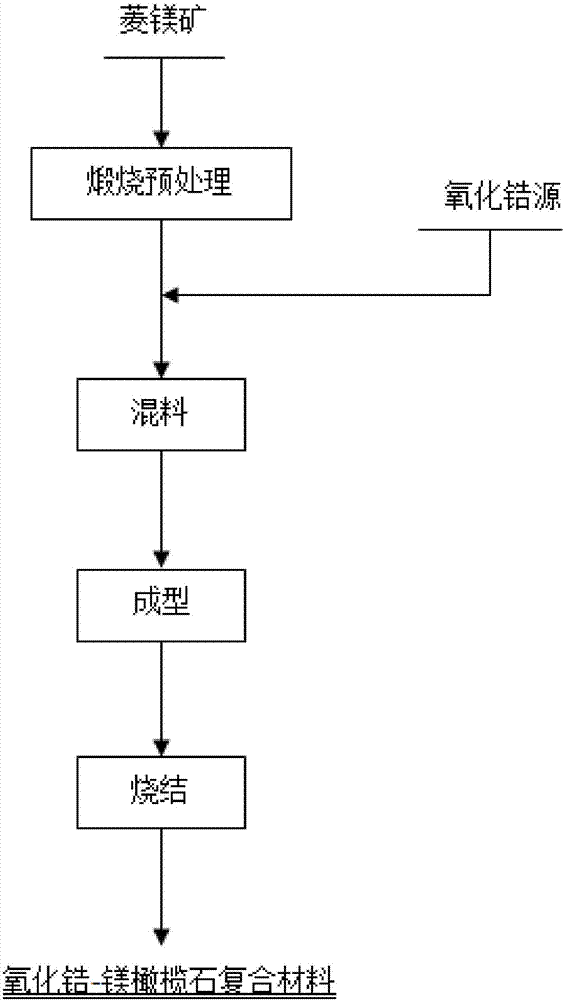

Method used

Image

Examples

Embodiment 1

[0035] (1) After fully crushing the magnesite, calcining at 750°C for 2 hours to obtain light-burned magnesia powder;

[0036] (2) Evenly mix light-burned magnesia and zircon by mass fraction 40%, 60%, and dry-mill in a ball mill for 10 hours;

[0037] (3) The raw material through ball milling is made into a green body under pressure at 150MPa for 5min;

[0038] (4) The green body is kept at 1300°C for 6 hours, and then cooled with the furnace to obtain the final product.

[0039] The performance parameters of the prepared zirconia-forsterite composite material are as follows: the apparent porosity is 14%, and the bulk density is 3.2 g cm -3 , The room temperature compressive strength is 163MPa.

Embodiment 2

[0041] (1) After fully crushing the magnesite, calcining at 750°C for 2 hours to obtain light-burned magnesia powder;

[0042] (2) Mixing light-burned magnesia and zircon by mass fraction 45%, 55%, dry grinding in a ball mill for 10h;

[0043] (3) The raw material through ball milling is made into a green body under pressure at 100MPa for 5min;

[0044] (4) The green body is kept at 1400°C for 4 hours, and then cooled with the furnace to obtain the final product.

[0045] The performance parameters of the prepared zirconia-forsterite composite material are as follows: the apparent porosity is 6%, and the bulk density is 3.7g cm -3 , The room temperature compressive strength is 188MPa.

Embodiment 3

[0047] (1) After the magnesite is fully crushed, it is calcined at 750°C for 2 hours to obtain lightly calcined magnesium oxide powder;

[0048] (2) Mixing light-burned magnesia and zircon by mass fraction 45%, 55%, dry grinding in a ball mill for 10h;

[0049] (3) The raw material through ball milling is made into a green body under pressure at 100MPa for 5min;

[0050] (4) The green body is kept at 1600°C for 4 hours, and the product is obtained by cooling with the furnace.

[0051] The performance parameters of the prepared zirconia-forsterite composite material are as follows: the apparent porosity is 3%, and the bulk density is 3.8 g cm -3 , The room temperature compressive strength is 245MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com