Preparation method of hexafluoroethane

A technology of hexafluoroethane and tetrafluoroethylene, applied in the field of preparation of hexafluoroethane, can solve problems such as affecting the service life of equipment, and achieve the effects of reducing production cost, easy control, and avoiding carbon bond breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

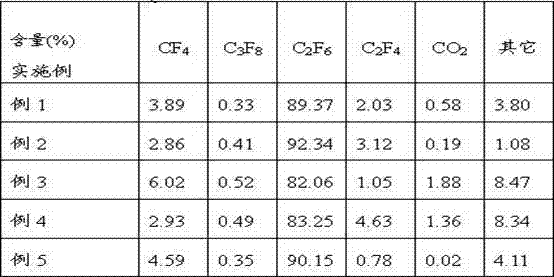

Examples

Embodiment 1

[0037] Put cobalt difluoride into the reactor (dimensions ¢57×3.5×560), then heat the reactor, use nitrogen to purge the reaction device during the temperature rise, after the internal temperature of the reactor rises to 250°C and the temperature is stable, put The fluorine gas is fed into the reactor to prepare the fluorinating agent. The outlet of the reactor is connected to the aftertreatment system to prevent the fluorine gas from leaking to the outside world. After the reaction, the reactor is replaced and vacuumized, and the reactor is heated to 300° C.; when the temperature is reached, tetrafluoroethylene is added for reaction. After the reaction and replacement, enter the next cycle and start the preparation of the fluorinating agent. In industrial continuous production, two or more reactors can be used for alternate production. The final product obtained is washed with 13% potassium hydroxide alkali, washed with water, adsorbed by molecular sieves, and then purified...

Embodiment 2

[0039] In this embodiment, the reaction temperature between the fluorinating agent and tetrafluoroethylene is set at 270° C., and the implementation steps and parameters are the same as those in Embodiment 1.

Embodiment 3

[0041] In this embodiment, the reaction temperature between the fluorinating agent and tetrafluoroethylene is set at 330° C., and the implementation steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com