Preparation method of polymer foam-based multi-stage carbon nanocomposite pressure-sensitive material

A technology of carbon nanocomposite and pressure-sensitive materials, which is applied in the field of preparation of polymer foam-based multi-level carbon nanocomposite pressure-sensitive materials, can solve problems such as complex procedures, high requirements, and high costs, and achieve strong operation controllability and quality Lightweight, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

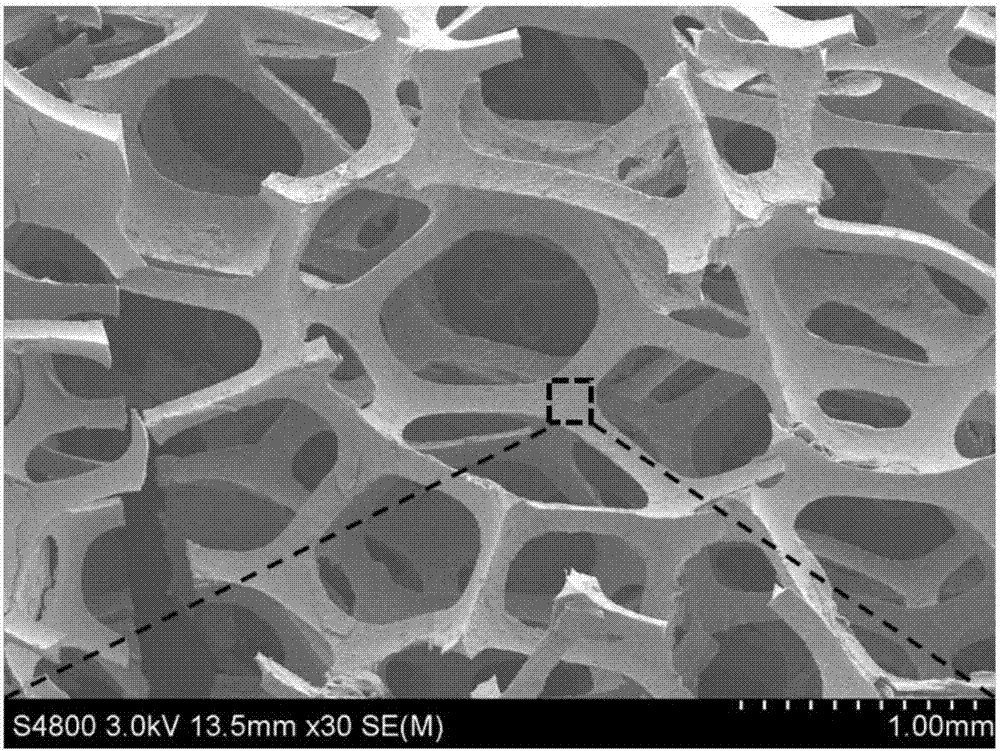

[0024] A method for preparing a polymer foam-based multi-stage carbon nanocomposite pressure-sensitive material of the present invention, specifically comprising the following steps:

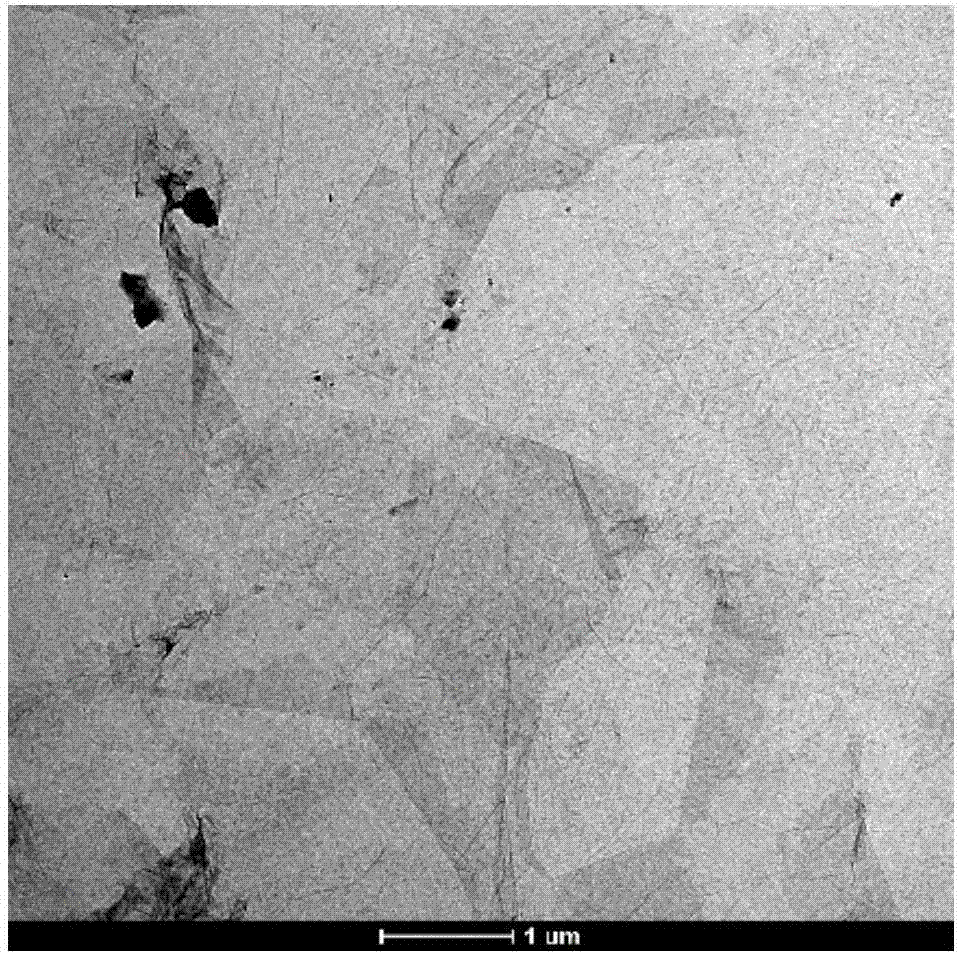

[0025] Step 1, dispersing graphene oxide (GO) into deionized water, and ultrasonically dispersing to obtain a negatively charged graphene aqueous dispersion;

[0026] The graphene oxide concentration in the graphene oxide aqueous dispersion in step 1 is 1.5-6 mg / mL.

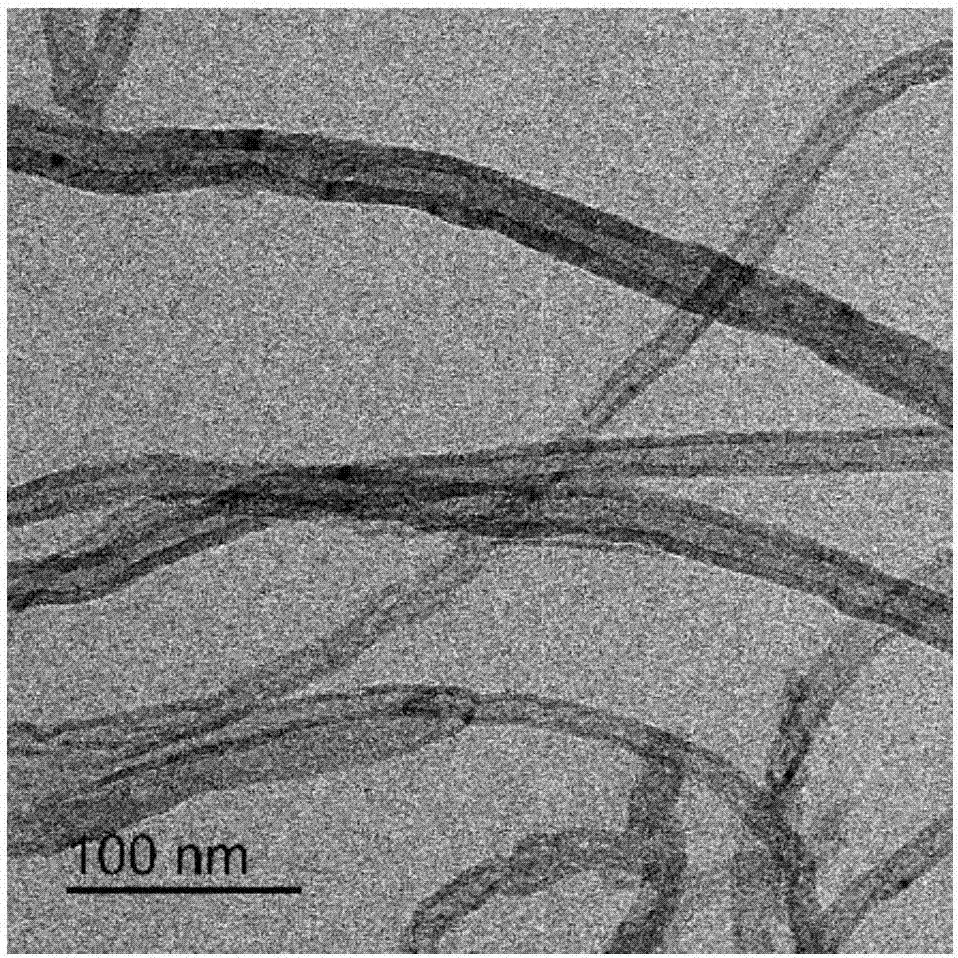

[0027] Step 2, using γ-aminopropyltriethoxysilane (AMEO) in a toluene solvent protected by a nitrogen atmosphere at 60-100°C for 12-24 hours under reflux reaction to carry out surface modification of hydroxylated carbon nanotubes (CNT-OH) Silane, centrifugally washed and freeze-dried, the obtained aminosilane-modified carbon nanotubes (AMEO-CNTs) were dispersed in deionized water, and hydrochloric acid solution was added dropwise to adjust the pH to 5-6 to obtain positively charged aminosilane-modified carbon nanotubes tube (AMEO-...

Embodiment 1

[0036]Weigh 0.045g graphene oxide (GO) and disperse it into 30mL deionized water, and ultrasonically disperse to obtain a negatively charged GO aqueous dispersion with a concentration of 1.5mg / mL; reflux reaction in toluene solvent at 60°C for 12 hours to modify the surface of hydroxylated carbon nanotubes with aminosilane, centrifuge washing and freeze-drying to obtain aminosilane-modified carbon nanotubes; weigh 0.045g of aminosilane-modified carbon nanotubes and disperse them into 30mL In deionized water, add hydrochloric acid solution to adjust the pH to 5 to obtain a positively charged aminosilane-modified carbon nanotube aqueous dispersion with a concentration of 1.5 mg / mL; immerse the polyurethane sponge in the graphene (GO) aqueous dispersion and gently Squeeze repeatedly, take it out after saturation, and dry it in an oven at 90°C; immerse the dried polyurethane sponge-based graphene (GO) composite material in the aqueous dispersion of aminosilane-modified carbon nanot...

Embodiment 2

[0038] Weigh 0.09g graphene oxide (GO) and disperse it into 30mL deionized water, and ultrasonically disperse to obtain a negatively charged GO aqueous dispersion with a concentration of 3.0mg / mL; Hydroxylated carbon nanotubes were surface-modified with aminosilane at 100°C for 24 hours in toluene solvent, washed by centrifugation and freeze-dried to obtain aminosilane-modified carbon nanotubes; weigh 0.09g AMEO-CNTs and disperse them into 30mL deionized water, drop Add hydrochloric acid solution to adjust the pH to 5, and obtain a positively charged AMEO-CNTs aqueous dispersion with a concentration of 3.0mg / mL; immerse the polyurethane sponge in the GO aqueous dispersion and squeeze it gently repeatedly, and take it out in an oven at 60°C after saturation Drying; the dried polyurethane sponge-based GO composite material was immersed in the AMEO-CNTs aqueous dispersion and squeezed repeatedly, and after saturation, it was taken out and dried in an oven at 90°C to obtain a layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com