Biochar based on nitric nitrogen adsorption in soil and preparation method

A technology of biochar and nitrate nitrogen, applied in the restoration of contaminated soil, chemical instruments and methods, and other chemical processes, can solve the problems of unsatisfactory results, low nitrate nitrogen adsorption or removal efficiency, etc., and achieve easy Achieved by carbonization, long-lasting effects, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

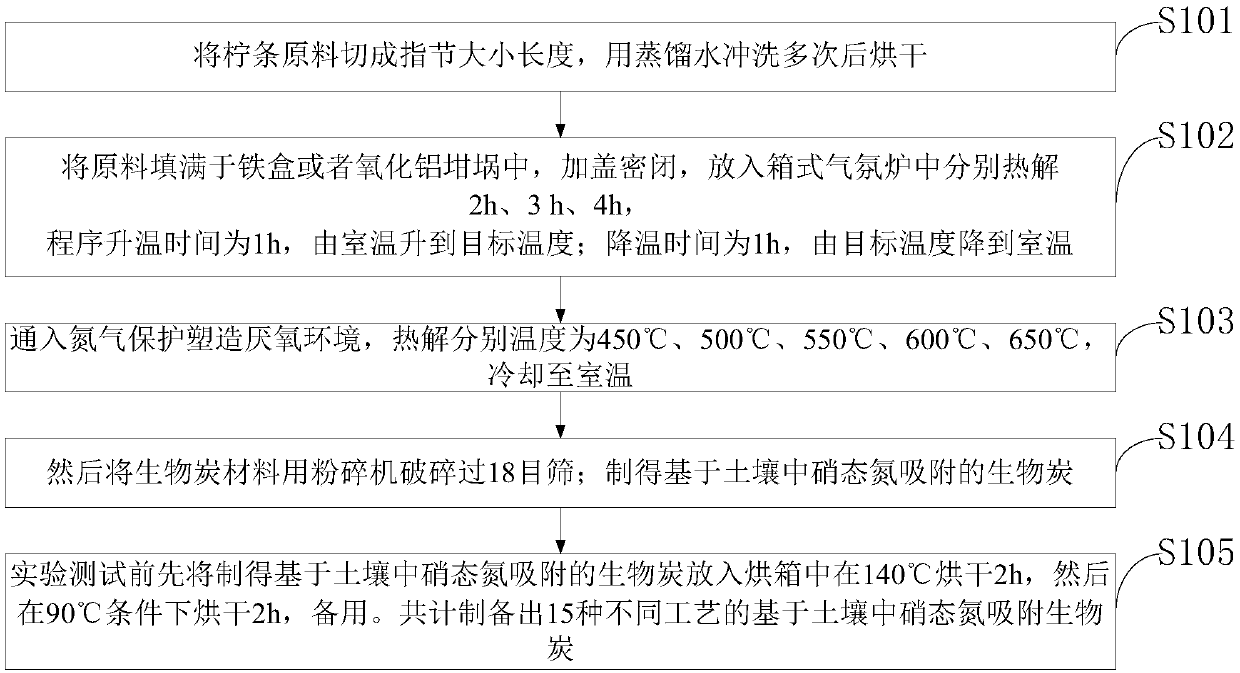

[0029] Such as figure 1 As shown, the preparation method of biochar based on the adsorption of nitrate nitrogen in soil provided by the embodiment of the present invention comprises the following steps:

[0030] S101: Cut the caragana raw material into knuckle-sized lengths, rinse with distilled water several times, and then dry;

[0031] S102: Fill the raw materials in an iron box or an alumina crucible, seal it with a cover, and put it into a box-type atmosphere furnace for pyrolysis for 2 hours, 3 hours, and 4 hours respectively. The programmed temperature rise time is 1 hour, from room temperature to the target temperature; cool down The time is 1h, from the target temperature to room temperature;

[0032] S103: Introduce nitrogen protection to create an anaerobic environment, pyrolysis temperature is 450°C, 500°C, 550°C, 600°C, 650°C respectively, and cool to room temperature;

[0033] S104: Then crush the biochar material with a pulverizer and pass through an 18-mesh s...

Embodiment 1

[0057] Wash, dry, crush, and extrude Caragana bar to obtain about 3cm caragana section; under the condition of nitrogen protection, put the above Caragana section in an alumina crucible, cover and seal it, and put it into a box-type atmosphere furnace In the process, heat up to 550°C at a rate of 8°C / min and pyrolyze for 1 hour, then cool to room temperature to obtain a crude product; crush the crude product and pass through a 18-mesh sieve to obtain biochar with a particle size of less than 1mm.

[0058] After adding 2 g / L of the prepared biochar into the water body with a pH of 7 and a nitrate nitrogen concentration of 50 ppm, immediately seal the water body, shake it on a constant temperature shaker at 25°C for 4 hours, filter it, and take the supernatant to measure the nitrate concentration. nitrogen content.

[0059] The specific surface area of the biochar in this embodiment, the percentage content of phenolic hydroxyl groups, and the removal rate of nitrate nitrogen i...

Embodiment 2

[0061] Wash, dry, crush and extrude caragana to obtain about 3cm caragana section; under the protection of argon, place the above caragana section in an alumina crucible, cover and seal it, and put it into a box-type atmosphere In the furnace, heat up to 600°C at a rate of 8°C / min and pyrolyze for 1 hour, cool to room temperature to obtain a crude product; crush the crude product and pass through a 18-mesh sieve to obtain biochar with a particle size of less than 1mm.

[0062] After adding 2 g / L of the prepared biochar into the water body with a pH of 7 and a nitrate nitrogen concentration of 50 ppm, immediately seal the water body, shake it on a constant temperature shaker at 25°C for 4 hours, filter it, and take the supernatant to measure the nitrate concentration. nitrogen content.

[0063] The specific surface area of the biochar in this embodiment, the percentage content of phenolic hydroxyl groups, and the removal rate of nitrate nitrogen in water are shown in Table 4....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Pyrolysis temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com