Method for preparing manganese ferrite spinel material by utilizing high-lead and high-phosphorus manganese resource, and additive

A technology of manganese ferrite spinel and lead high phosphorus manganese, which is applied in the fields of inorganic material magnetism, chemical instruments and methods, iron compounds, etc., can solve the problem of difficult separation of harmful elements and manganese minerals, and achieve enhanced deleading and dephosphorization , strengthen roasting, promote the effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

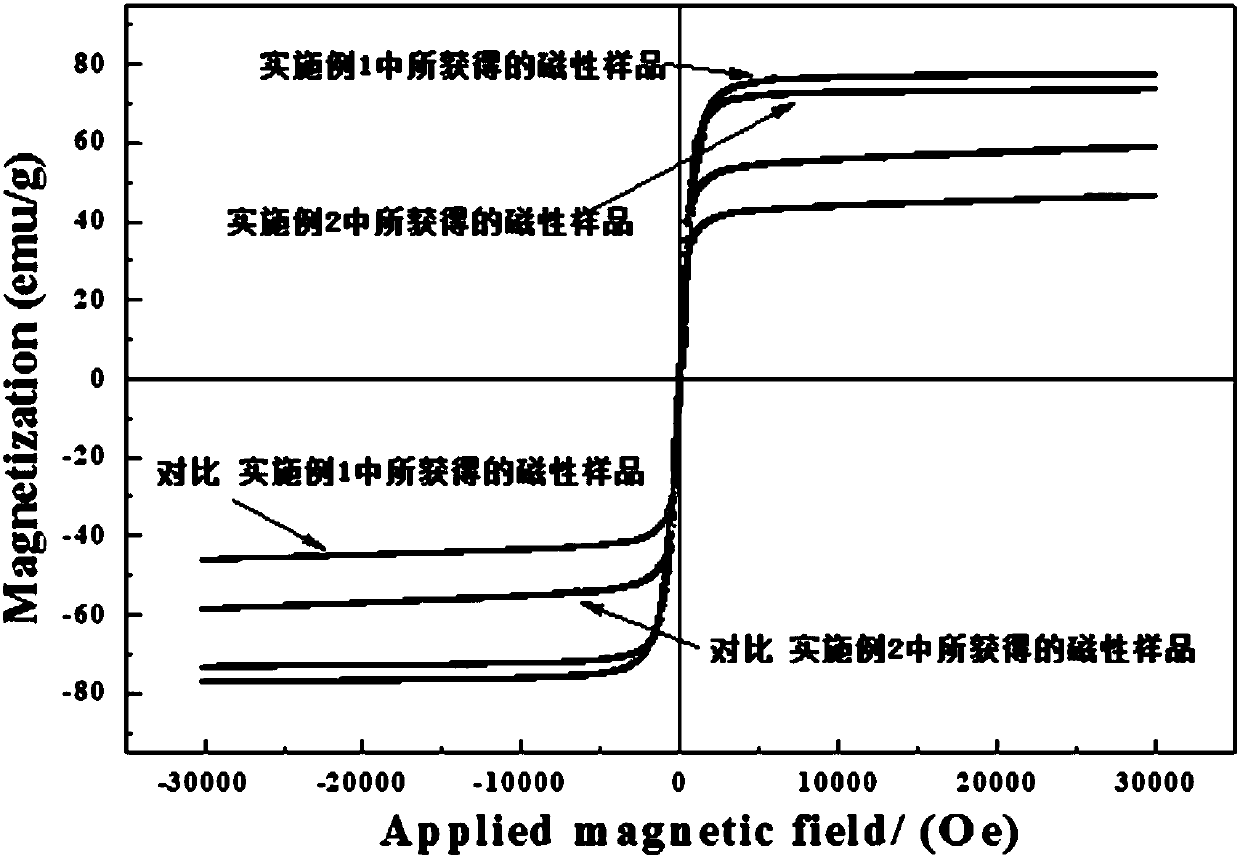

Embodiment 1

[0035] High phosphorus and high lead manganese resources (manganese anode slime TMn 40.4%, Pb 10.5%; ferromanganese ore TMn 20.6%, Pb 3.5%, P 1.0%), additives (60% iron resources: hematite, magnetite ; 30% calcium flux: quicklime; 10% sodium salt: 10% sodium carbonate+90% sodium oxalate) for batching, the composition of the mixture is TMn21%, TFe42%, (CaO+Na 2 O) / SiO 2 =0.05, the mass percentage of the mixture-325 mesh particle size is 95%, and the specific surface area is 2600cm 2 / g, add 0.25% bentonite and 8% water, make pellets, then dry, roast the dried samples in a muffle furnace, the roasting temperature is 1300°C, the roasting time is 2h, and grind the roasted samples after cooling The mass percentage of the particle size to -325 mesh is 99.5%, and the magnetic separation is carried out in a magnetic field with a magnetic field strength of 500Gs, and the obtained magnetic product is a multilayer manganese-ferro-spinel material. The magnetic properties of the magnetic...

Embodiment 2

[0037] High-phosphorus and high-lead manganese resources (manganese anode slime TMn 43.2%, Pb 9.6%; ferromanganese ore TMn 14.4%, Pb 2.8%, P 0.9%), additives (65% iron-containing resources: hematite, magnetite ; 25% calcium flux: quicklime; 10% sodium salt: 10% sodium sulfate+10% borax+80% sodium oxalate) for batching, the composition of the mixture is TMn16%, TFe40%, (CaO+Na 2 O) / SiO 2 =0.45, the mass percentage of the mixture-325 mesh particle size is 95%, and the specific surface area is 2500cm 2 / g, add 0.25% bentonite and 8% water, make pellets, then dry, roast the dried samples in a muffle furnace, the roasting temperature is 1200°C, the roasting time is 5h, and the roasted samples are ground after cooling The mass percentage of the particle size to -325 mesh is 100%, and the magnetic separation is carried out in a magnetic field with a magnetic field strength of 800Gs, and the obtained magnetic product is a multilayer manganese-ferro-spinel material. The magnetic prop...

Embodiment 3

[0039] High phosphorus and high lead manganese resources (manganese anode slime TMn 40.8%, Pb 8.3%; ferromanganese ore TMn 14.4%, Pb 2.8%, P 0.9%), additives (80% iron resources: high phosphorus oolitic hematite , magnetite; 10% calcium flux: quicklime, limestone; 10% sodium salt: 5% sodium sulfate+5% borax+90% sodium oxalate) for batching, the composition of the mixture is TMn20%, TFe31%, (CaO +Na 2 O) / SiO 2 =0.30, the mass percentage of the mixture-325 mesh particle size is 95%, and the specific surface area is 2650cm 2 / g, add 0.25% bentonite and 8% water to make pellets, then dry, roast the dried samples in a muffle furnace, the roasting temperature is 1250°C, and the roasting time is 5h, and the roasted samples are ground after cooling The mass percentage of the particle size to -325 mesh is 100%, and the magnetic separation is carried out in a magnetic field with a magnetic field strength of 700Gs, and the obtained magnetic product is a multilayer manganese-ferro-spine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com